Team:Heidelberg/Templates/Modelling/Ind-Production

From 2013.igem.org

m |

m |

||

| Line 2: | Line 2: | ||

<div class="container"><div class="row" style="float:left"><div class="col-sm-12"> | <div class="container"><div class="row" style="float:left"><div class="col-sm-12"> | ||

<h2 id="Challenge"> Challenge </h2> | <h2 id="Challenge"> Challenge </h2> | ||

| - | A challenge we had to face during the <a href="https://2013.igem.org/Team:Heidelberg/Project/Tag-Optimization"><u>characterization and optimization of indC</u></a> was to identify the production kinetics of | + | A challenge we had to face during the <a href="https://2013.igem.org/Team:Heidelberg/Project/Tag-Optimization"><u>characterization and optimization of indC</u></a> was to identify the production kinetics of indigoidine. |

| - | In order to disentangle the underlying mechanisms of bacterial growth and peptide synthesis, we decided to set up a mathematical model based on coupled ordinary differential equations (ODEs). Calibrated with our experimental time-resolved data, the mathematical model could potentially not only elucidate how | + | In order to disentangle the underlying mechanisms of bacterial growth and peptide synthesis, we decided to set up a mathematical model based on coupled ordinary differential equations (ODEs). Calibrated with <a class="fancybox fancyGraphical" href="https://static.igem.org/mediawiki/2013/3/38/Heidelberg_IndPD_Fig11.png" caption="<b>Figure 9: Indigoidine Production Varies Among Engineered Indigoidine Synthetases.</b> |

| + | The absorption spectrum of liquid cultures expressing engineered variants of the indC indigoidine synthetase were measured for 30 hours. The graphs show the OD590 of indigoidine in <i>E. coli</i> liquid cultures over time. The absorption of the cell suspension has been subtracted (see OD Measurement in the Methods section). The red graph relates to an <i>E. coli</i> TOP10 negative control, the green graph depicts the indigoidine production of an indC variant, in which the T-domain has been exchanged with our synthetic T-domain #3, whereas the blue graphs refers to synthetic T-domain #4. | ||

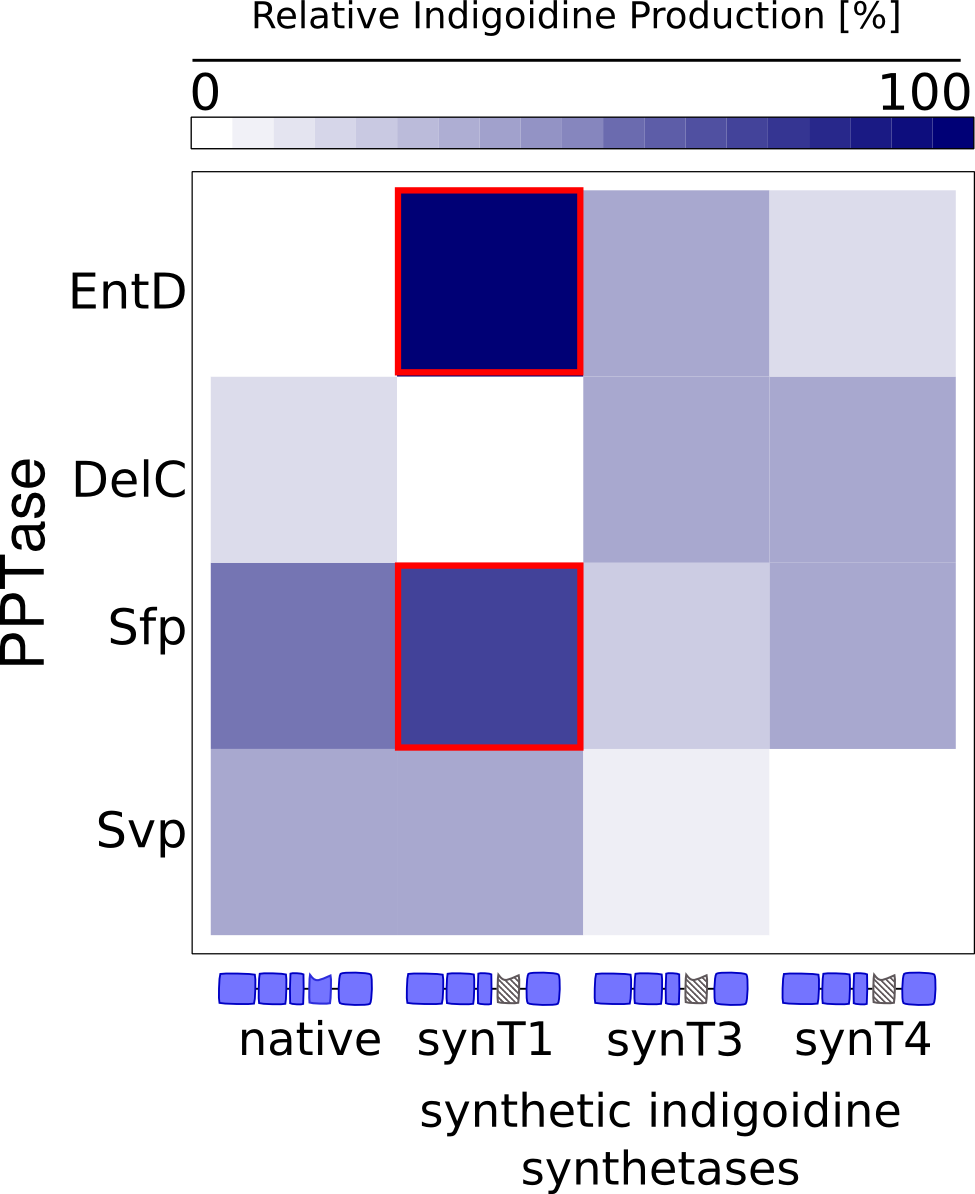

| + | The amount of indigoidine reaches a maximum before it drops again. This is due the instability of indigoidine, which is reduced to its fluorescent leuco-form under the influence of reducing agents, light and high temperature (Takahashi 2007). The local absorption maximum at 590 nm (keto-indigoidine) decreases after 15-25 hours, whereas the absorption maximum at 430 nm (leuco-indigoidine) increases (data not shown). Note that the maximum level of indigoidine differs among the engineered indigoidine synthetases.">our experimental time-resolved data</a>, the mathematical model could potentially not only elucidate how indigoidine production influences growth of bacteria but also provide a more quantitative understanding of the synthesis efficiency of <a class="fancybox fancyGraphical" href="https://static.igem.org/mediawiki/2013/4/4d/Heidelberg_IndPD_Fig10.png" caption="<b>Figure 8: Indigoidine Production Depend on Combination of T-domain and PPTase</b> | ||

| + | The absorption spectrum of liquid cultures expressing engineered variants of the indC indigoidine synthetase were measured for 30 hours. The graphs show the OD590 of indigoidine in <i>E. coli</i> liquid cultures over time. The absorption of the cell suspension has been subtracted (see OD Measurement in the Methods section). The left diagram shows the indigoidine production over time of a liquid culture expressing an engineered indigoidine synthetase with the synthetic T-domain #1 (synT1) and a PPTase, whereas each graph refers to a specific PPTase coexpressed. The diagram on the right shows the corresponding data for the indigoidine synthetase with the synthetic T-domain #3 (synT3). | ||

| + | The indigoidine production correlates to the combination of a T-domain with a respective PPTase and the PPTases vary in their ability to activate T-domains. For example, DelC is unable to activate synT 1 but activates synT3, whereas svp activates synT1 but is unable to activate synT3. Note also, that activation of synT3 by EntD results in the highest amount of indigoidine production among all the combinations shown.">the different T domains and PPTases</a> that were tested. | ||

<h2 id="Approach"> Approach </h2> | <h2 id="Approach"> Approach </h2> | ||

<p> | <p> | ||

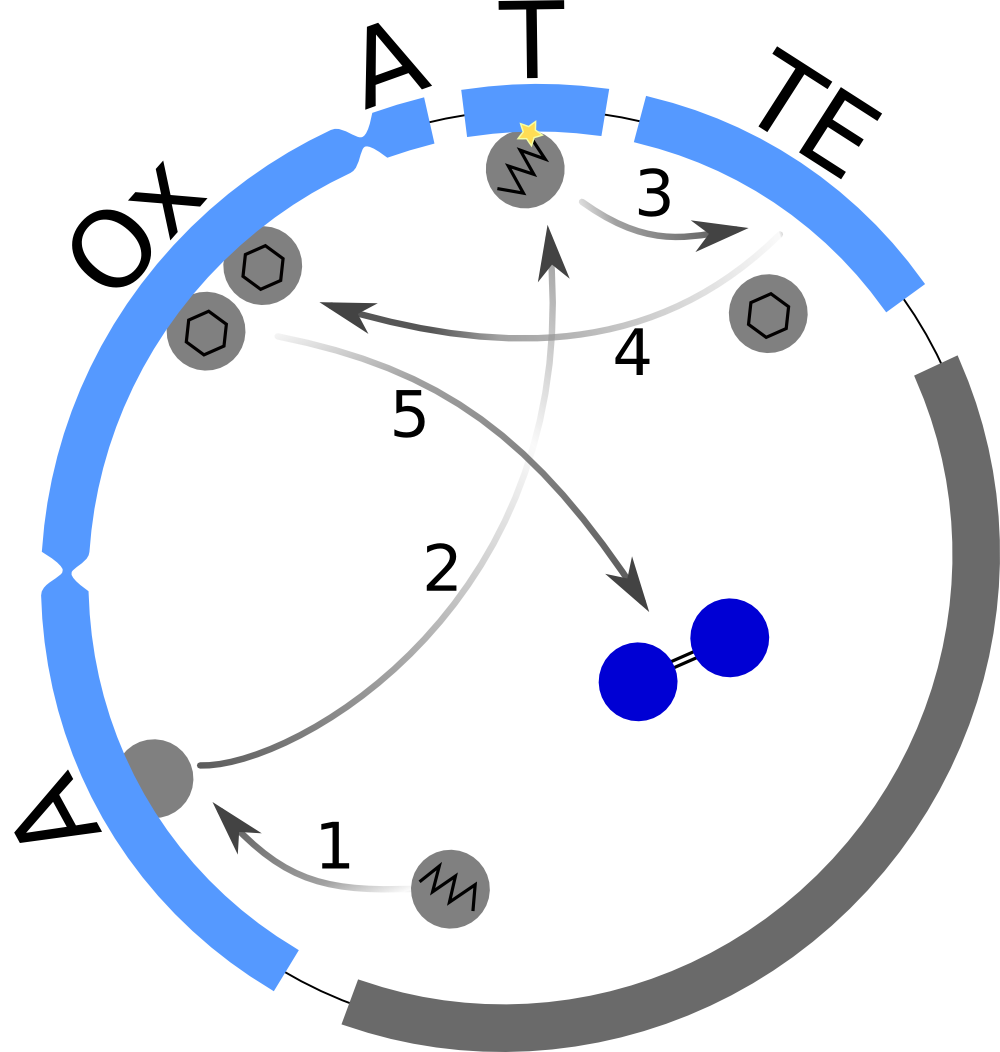

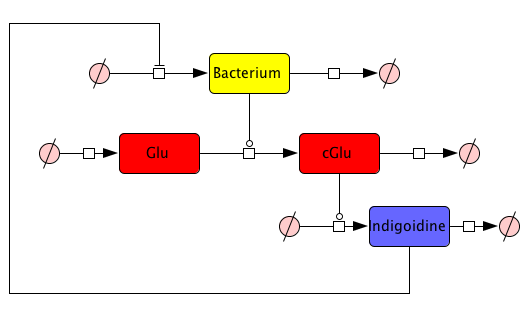

| - | First, we set up a mind model based on the fact that the functional | + | First, we set up a mind model based on the fact that the functional indigoidine dimer is produced from two glutamines (Glu) that are each cyclized (cGlu) ref[Brachmann, Alexander O, Kirchner, Ferdinand, Kegler, Carsten, Kinski, Sebastian C, Schmitt, Imke, Bode, Helge B: Triggering the production of the cryptic blue pigment indigoidine from Photorhabdus luminescens., J. Biotechnol. 157(1), 969, January 2012] (<a class="fancybox fancyFigure" href="/wiki/images/8/83/Heidelberg_IndSynthesis_scheme.png" title="<b>Figure 1: The indigoidine synthetase indC produces a blue pigment and is used for the indigoidine-tag</b>. After activation of L-glutamine by the A domain and its binding to the T domain, it is cyclized by the TE domain and oxidized by the Ox domain. Dimerization is thought to happen by air.">Fig. 1</a>), and our observation that indigoidine (Ind)-producing bacteria (Bac) <a class="fancybox fancyGraphical" href="https://static.igem.org/mediawiki/2013/c/cf/Heidelberg_IndPD_Fig6.png" caption="<b>Figure 3: Comparison between different <em>E. coli</em> strains and PPTases:</b> |

| + | <b>a)</b> Comparison of different <em>E. coli</em> strains examining growth and indigoidine production | ||

| + | The figure shows five different strains of <em>E. coli</em> that have been co-transformed with an indC expression plasmid and a sfp expression plasmid. The negative control is <em>E. coli</em> TOP10 without a plasmid. All transformants have been grown on LB agar for 48 hours at room temperature, cells were not induced. One can see that even without induction all strains express the indigoidine synthetase and produce the blue pigment indigoidine. However, the strains BAP1 and NEB Turbo grow faster in the first day, exhibiting a white phenotype (data not shown). Colonies on the plate of <em>E. coli</em> TOP10 are very small and dark blue/ black. Assuming that indigoidine production inhibits cell growth due to its toxicity, we concluded that TOP10 produced the most indigoidine among the strains we tested. We used <em>E. coli</em> TOP10 for the following experiments. | ||

| + | <b>b)</b> Comparison between different PPTases concerning overall indigoidine production | ||

| + | The Figure shows <i>E. coli</i> TOP10 cells co-transformed with indC and four different PPTases (sfp, svp, entD and delC), respectively. The image bottom left shows <i>E. coli</i> TOP10 cells without additional PPTase and the negative control is TOP10 without a plasmid. | ||

| + | ">grow slower</a> than mock controls. Those hypotheses resulted in a general model scheme depicting the interdependency between indigoidine synthesis and bacterial growth. With the mathematical model, we could then validate whether there is indeed a negative feedback from the indigoidine production to the growth of bacteria. | ||

</p> | </p> | ||

<center> | <center> | ||

| Line 16: | Line 25: | ||

</center> | </center> | ||

<p> | <p> | ||

| - | Since we had already established our quantitative | + | Since we had already established our quantitative indigoidine production assay (see <a href="https://2013.igem.org/Team:Heidelberg/Project/Tag-Optimization"><u>Tag-Optimization</u></a>) in a time-dependent manner, we wanted to further exploit these experimental data via quantitative dynamic modeling. The change of bacteria and Indigoidine with time was measured via <a class="fancybox fancyGraphical" href="https://static.igem.org/mediawiki/2013/6/64/Heidelberg_IndPD_Fig5.png" caption="<b>Figure 13: Quantification of dye in cellular culture by OD measurements at robust and sensitive wavelengths. </b>The contribution of the scattering by the cellular components at the sensitive wavelength, i.e. 590 nm for indigoidine has to be subtracted from the overall OD at this wavelength. For a detailed description of the calculation refer to text below. |

| - | Such ODEs contain parameters that characterize e.g. growth or synthesis rates for bacteria or | + | Figure adopted from [15] ">optical density</a> of the liquid cultures in a 96-well plate of a TECAN reader and can be described in ordinary differential equations (ODEs). |

| + | Such ODEs contain parameters that characterize e.g. growth or synthesis rates for bacteria or indigoidine, respectively. | ||

</p> | </p> | ||

<h3 id="ODEs">Ordinary Differential Equations (ODEs)</h3> | <h3 id="ODEs">Ordinary Differential Equations (ODEs)</h3> | ||

<p> | <p> | ||

| - | + | How to find proper equations for bacterial growth and indigoidine synthesis? | |

From our mind model (<a class="fancybox fancyFigure" href="/wiki/images/0/03/Network_native.png" title="<b>Figure 2: Schematic representation of a mathematical model describing bacterial Indigoidine synthesis</b>. ....">Fig. 2</a>), we derived ODEs based on mass-action kinetics <bib id="17118154"/>. However, bacterial growth curves cannot be sufficiently described by mass action, thus we adapted our ODE for the bacterial growth from equation (7) of Kenneth and Kamau, 1993 <bib id="pmid24123647"/>. | From our mind model (<a class="fancybox fancyFigure" href="/wiki/images/0/03/Network_native.png" title="<b>Figure 2: Schematic representation of a mathematical model describing bacterial Indigoidine synthesis</b>. ....">Fig. 2</a>), we derived ODEs based on mass-action kinetics <bib id="17118154"/>. However, bacterial growth curves cannot be sufficiently described by mass action, thus we adapted our ODE for the bacterial growth from equation (7) of Kenneth and Kamau, 1993 <bib id="pmid24123647"/>. | ||

Our ODE system is now given by the following 4 equations: | Our ODE system is now given by the following 4 equations: | ||

| Line 107: | Line 117: | ||

<p> | <p> | ||

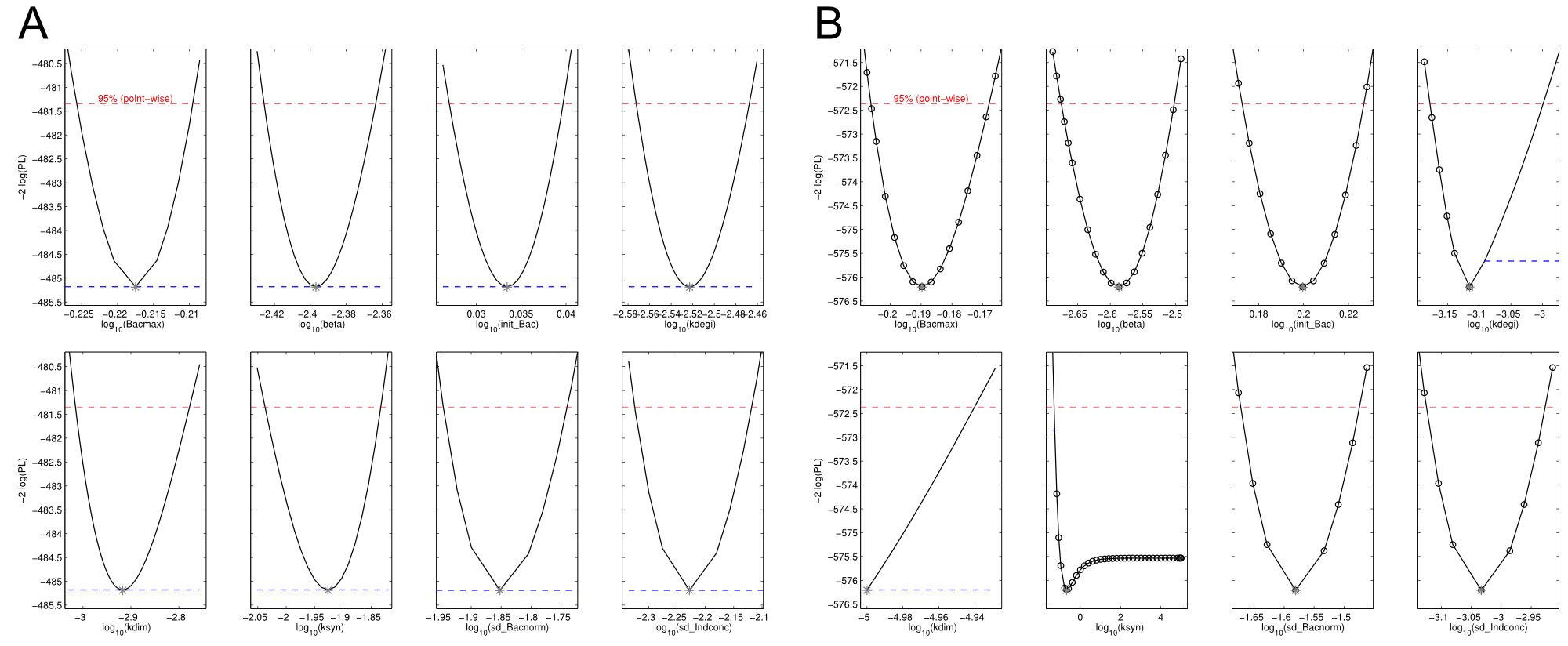

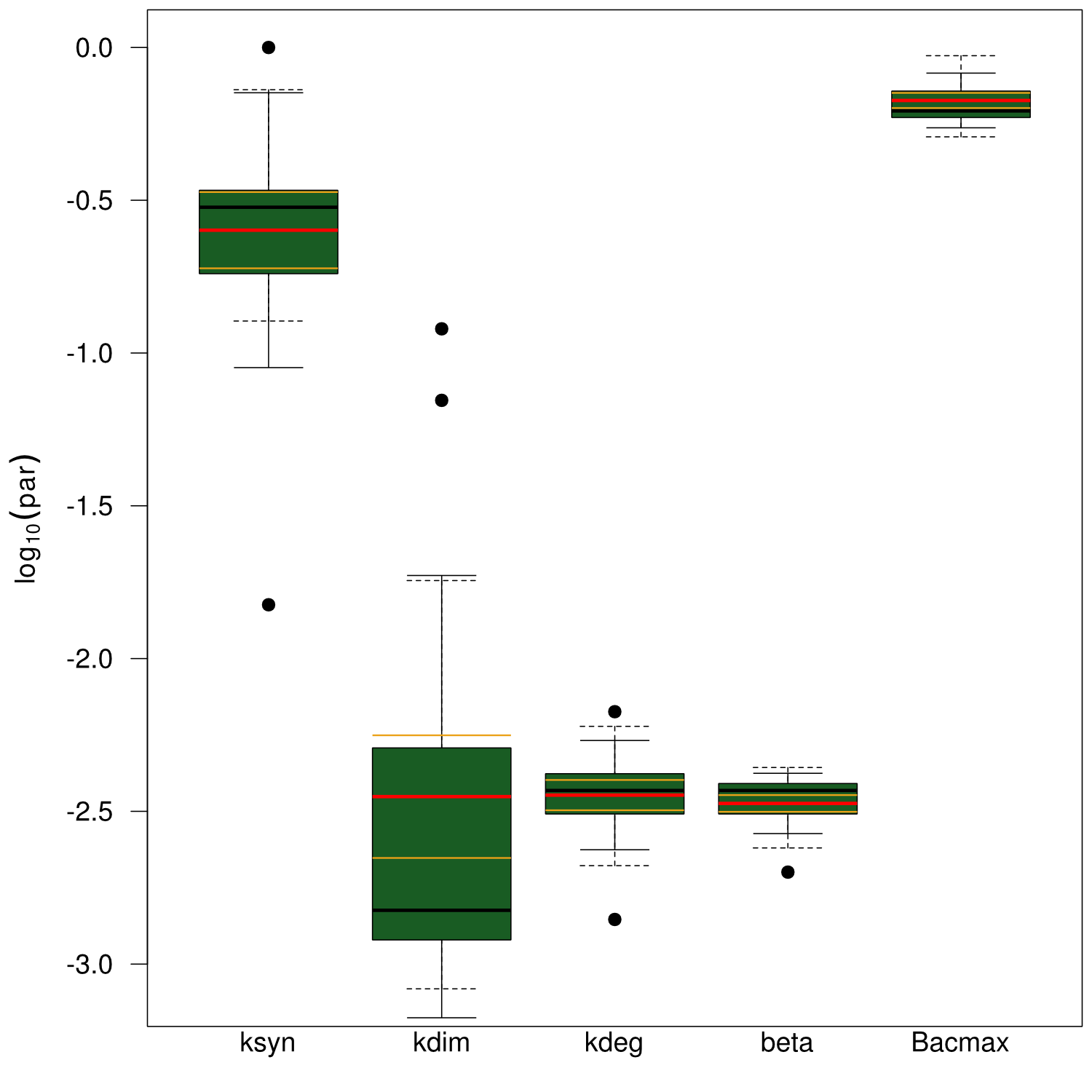

Interestingly, the bacterial growth rate beta and the maximum growth capacity Bacmax were very consistent. | Interestingly, the bacterial growth rate beta and the maximum growth capacity Bacmax were very consistent. | ||

| - | The parameters ksyn, kdim and kdegi contributed directly to indogoidine synthesis as it can be inferred from the above mentioned equations | + | The parameters ksyn, kdim and kdegi contributed directly to indogoidine synthesis as it can be inferred from the above mentioned equations \eqref{glu}, \eqref{cglu} and \eqref{ind}. |

The synthesis rate ksyn characterizes the cyclization of glutamine. The dimerization rate kdim reflects how two cyclized glutamine molecules form one indgoidine molecule. As such, ksyn and kdim represent the efficiency of the T domain of indC. | The synthesis rate ksyn characterizes the cyclization of glutamine. The dimerization rate kdim reflects how two cyclized glutamine molecules form one indgoidine molecule. As such, ksyn and kdim represent the efficiency of the T domain of indC. | ||

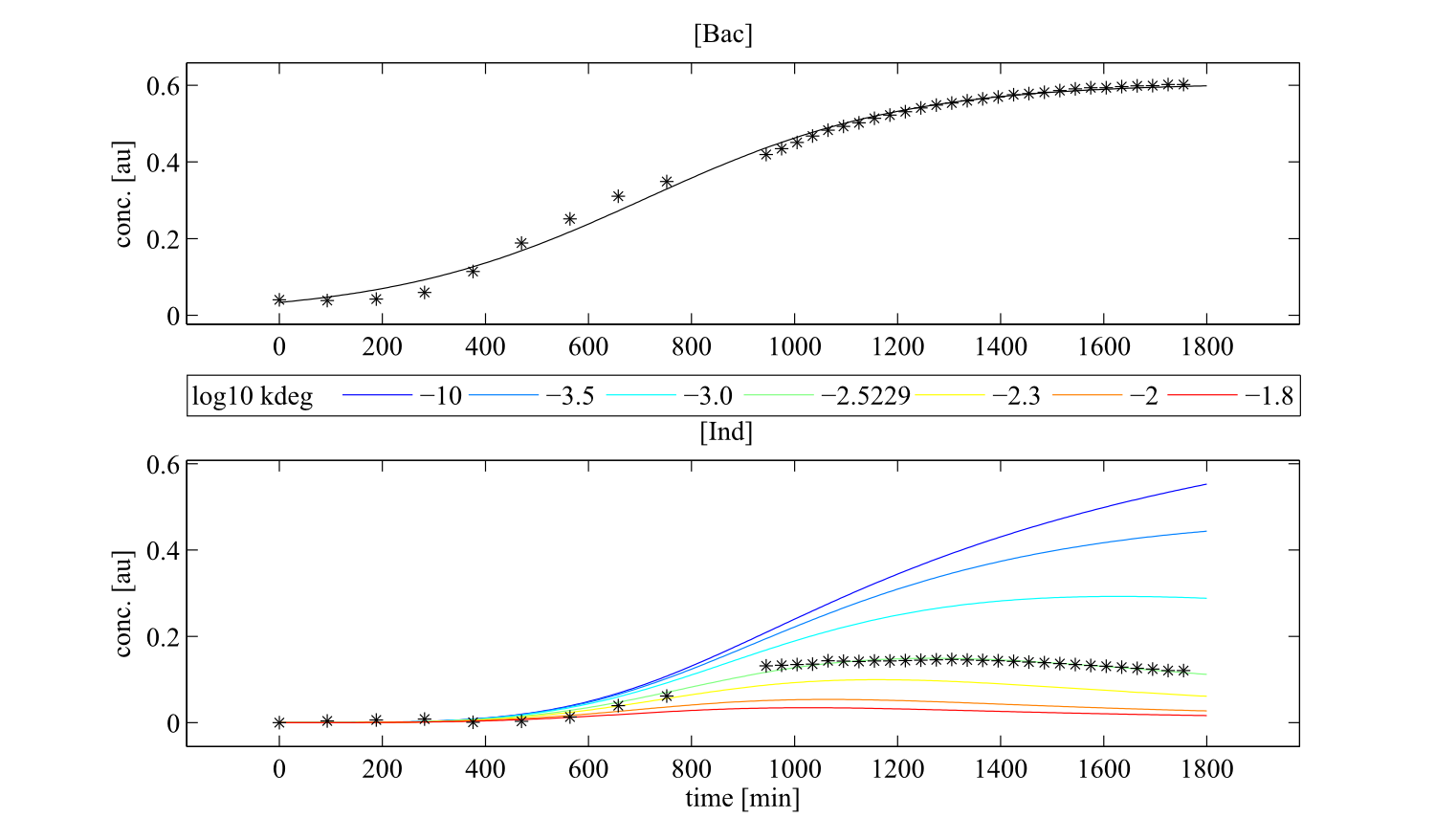

The degradation rate of indigoidine, kdegi, should be independent from the domain structure of the indigoidine synthetase as the stability of the peptide is not affected by the T domains or the PPTases that were tested. The rate did not vary widely and the diverse data sets could still be explained by the mathematical model. At first glance, kdegi seemed less important for our experimentally assessed conditions. To further investigate the role of kdegi for indigoidine production kinetics, we systematically varied this parameter and compared simulation results. | The degradation rate of indigoidine, kdegi, should be independent from the domain structure of the indigoidine synthetase as the stability of the peptide is not affected by the T domains or the PPTases that were tested. The rate did not vary widely and the diverse data sets could still be explained by the mathematical model. At first glance, kdegi seemed less important for our experimentally assessed conditions. To further investigate the role of kdegi for indigoidine production kinetics, we systematically varied this parameter and compared simulation results. | ||

| - | The synthesis of indigoidine was clearly affected by variation of kdegi (Fig. | + | The synthesis of indigoidine was clearly affected by variation of kdegi (<a class="fancybox fancyFigure" href="/wiki/images/7/7b/Heidelberg_kdeg_variation_nsfp.png" title="<b>Figure 7: Dependency of indigoidine production on the degradation constant.</b>">Fig. 7</a>). The [Ind] trajectory collapsed more than 3-fold increase of the degradation rate. On the contrary, improved peptide stability could yield much more indigoidine. For very low degradation rates (i.e. kdegi < 1e-3), synthesis would not even saturate within the observed time frame. |

</p> | </p> | ||

<center> | <center> | ||

| Line 121: | Line 131: | ||

<h3 id="SensitivityAnalysis"> Sensitivity analysis for optimized indigoidine production </h3> | <h3 id="SensitivityAnalysis"> Sensitivity analysis for optimized indigoidine production </h3> | ||

<p> | <p> | ||

| - | To perceive the role of kdegi for indigoidine synthesis, we have varied the parameter over a broad range and observed qualitatively distinct model trajectories. For a more quantitative understanding of how indigoidine yield changes with altering parameters of the system, we conducted a sensitivity analysis (REVIEW NEEDED). | + | To perceive the role of kdegi for indigoidine synthesis, we have varied the parameter over a broad range and observed <a class="fancybox fancyFigure" href="/wiki/images/7/7b/Heidelberg_kdeg_variation_nsfp.png" title="<b>Figure 7: Dependency of indigoidine production on the degradation constant.</b>">qualitatively distinct model trajectories</a>. For a more quantitative understanding of how indigoidine yield changes with altering parameters of the system, we conducted a sensitivity analysis (REVIEW NEEDED). |

Therefore, we first defined the variable IntInd, the integrated indigoidine reflecting production yield. The change of the indigoidine concentration with time is determined by the ODE (4) and its integral with time can be depicted as the area under the [Ind] curve, i.e. the amount of indigoidine produced by the bacteria with time. Now we were interested in the change of IntInd with the change of the different parameters of our system. | Therefore, we first defined the variable IntInd, the integrated indigoidine reflecting production yield. The change of the indigoidine concentration with time is determined by the ODE (4) and its integral with time can be depicted as the area under the [Ind] curve, i.e. the amount of indigoidine produced by the bacteria with time. Now we were interested in the change of IntInd with the change of the different parameters of our system. | ||

| - | Mathematically, this is expressed as the so called sensitivity $\frac{\partial \mathrm{X}}{\partial \mathrm{p}}, with X as our variable of interest (IntInd) and p as the parameter (beta, Bacmax, ksyn, kdim or kdegi, respectively). This partial derivative provides a measure of how much X changes with the change of p or how sensitive X is against small variations in p. Sensitivities can be scaled with the actual values of X and the respective p to fall in the range from -1 to +1. The higher the absolute value of the sensitivity, the more important is the parameter for the variable. A positive sensitivity means positive impact of the parameter on the variable whereas a sensitivity < 0 indicates reduction of X for subtle decrease in p. | + | Mathematically, this is expressed as the so called sensitivity $\frac{\partial \mathrm{X}}{\partial \mathrm{p}}$, with X as our variable of interest (IntInd) and p as the parameter (beta, Bacmax, ksyn, kdim or kdegi, respectively). This partial derivative provides a measure of how much X changes with the change of p or how sensitive X is against small variations in p. Sensitivities can be scaled with the actual values of X and the respective p to fall in the range from -1 to +1. The higher the absolute value of the sensitivity, the more important is the parameter for the variable. A positive sensitivity means positive impact of the parameter on the variable whereas a sensitivity < 0 indicates reduction of X for subtle decrease in p. |

We utilised our mathematical model and computed the sensitivities of IntInd against the change of all five kinetic parameters of our system and scaled them accordingly. The analysis confirmed that the kdegi was the only parameter of the system that exhibited a negative impact on the indigoidine production (Tab. 1). Slight increase of all the other parameters also augmented additional yield. | We utilised our mathematical model and computed the sensitivities of IntInd against the change of all five kinetic parameters of our system and scaled them accordingly. The analysis confirmed that the kdegi was the only parameter of the system that exhibited a negative impact on the indigoidine production (Tab. 1). Slight increase of all the other parameters also augmented additional yield. | ||

</p> | </p> | ||

Revision as of 03:20, 29 October 2013

Challenge

A challenge we had to face during the characterization and optimization of indC was to identify the production kinetics of indigoidine. In order to disentangle the underlying mechanisms of bacterial growth and peptide synthesis, we decided to set up a mathematical model based on coupled ordinary differential equations (ODEs). Calibrated with our experimental time-resolved data, the mathematical model could potentially not only elucidate how indigoidine production influences growth of bacteria but also provide a more quantitative understanding of the synthesis efficiency of the different T domains and PPTases that were tested.Approach

First, we set up a mind model based on the fact that the functional indigoidine dimer is produced from two glutamines (Glu) that are each cyclized (cGlu) ref[Brachmann, Alexander O, Kirchner, Ferdinand, Kegler, Carsten, Kinski, Sebastian C, Schmitt, Imke, Bode, Helge B: Triggering the production of the cryptic blue pigment indigoidine from Photorhabdus luminescens., J. Biotechnol. 157(1), 969, January 2012] (Fig. 1), and our observation that indigoidine (Ind)-producing bacteria (Bac) grow slower than mock controls. Those hypotheses resulted in a general model scheme depicting the interdependency between indigoidine synthesis and bacterial growth. With the mathematical model, we could then validate whether there is indeed a negative feedback from the indigoidine production to the growth of bacteria.

Since we had already established our quantitative indigoidine production assay (see Tag-Optimization) in a time-dependent manner, we wanted to further exploit these experimental data via quantitative dynamic modeling. The change of bacteria and Indigoidine with time was measured via optical density of the liquid cultures in a 96-well plate of a TECAN reader and can be described in ordinary differential equations (ODEs). Such ODEs contain parameters that characterize e.g. growth or synthesis rates for bacteria or indigoidine, respectively.

Ordinary Differential Equations (ODEs)

How to find proper equations for bacterial growth and indigoidine synthesis?

From our mind model (Fig. 2), we derived ODEs based on mass-action kinetics

\begin{align} \mathrm{d}\mathrm{[Bac]}/\mathrm{d}t &= \frac{\mathrm{[Bac]} \cdot \left(\mathrm{[Bac]} - \mathrm{Bacmax}\right) \cdot \mathrm{beta}}{\mathrm{Bacmax}}\label{bacgrowth}\\ \mathrm{d}\mathrm{[Glu]}/\mathrm{d}t &= - \mathrm{[Bac]} \cdot \mathrm{[Glu]} \cdot \mathrm{ksyn}\label{glu}\\ \mathrm{d}\mathrm{[cGlu]}/\mathrm{d}t &= - \mathrm{kdim} \cdot {\mathrm{[cGlu]}}^2 + \mathrm{[Bac]} \cdot \mathrm{[Glu]} \cdot \mathrm{ksyn}\label{cglu}\\ \mathrm{d}\mathrm{[Ind]}/\mathrm{d}t &= {\mathrm{[cGlu]}}^2 \cdot \mathrm{kdim} - \mathrm{[Ind]} \cdot \mathrm{kdegi}\label{ind} \end{align}

Initially, inhibition of bacterial growth by indigoidine and degradation of cyclic glutamine were also described by the model, using equations \eqref{bacgrowthinhib} and \eqref{cgludeg} instead of \eqref{bacgrowth} and \eqref{cglu}, respectively, however the degradation rate turned out to be non-identifiable for all data sets, converging to the lower bound, whereas the growth inhibition term led to frequent convergence failures, the inhibition constant being very low in cases where convergence was achieved. These two terms were thus removed from the model. \begin{align} \mathrm{d}\mathrm{[Bac]}/\mathrm{d}t &= \frac{\mathrm{[Bac]} \cdot \left(\mathrm{[Bac]} - \mathrm{Bacmax}\right) \cdot \left(\mathrm{beta} - \mathrm{ki} \cdot \mathrm{[Ind]}\right)}{\mathrm{Bacmax}}\label{bacgrowthinhib}\\ \mathrm{d}\mathrm{[cGlu]}/\mathrm{d}t &= - \mathrm{kdim} \cdot {\mathrm{[cGlu]}}^2 - \mathrm{kdegg} \cdot \mathrm{[cGlu]} + \mathrm{[Bac]} \cdot \mathrm{[Glu]} \cdot \mathrm{ksyn}\label{cgludeg} \end{align}

This system contains 4 dynamic variables: Bacteria (Bac), Glutamine (Glu), cyclized Glutamine (cGlu) and Indigoidine (Ind) that change with time t. Bacteria and Indigoidine was experimentally measured, we thus call Bac and Ind observables of our system. The equations are described by 5 kinetic parameters:

- Bacmax: maximum capacity for bacterial growth

- beta: maximum attainable growth rate

- ksyn: synthesis rate of cyclized glutamine from glutamine

- kdim: dimerization rate of two cyclized glutamines to an Indigoidine dimer

- kdegi: degradation rate of indigoidine

In addition, the experimental error for the observables was estimated with 2 error parameters and the initial concentration of the bacteria at t=0 was estimated. Data was otherwise normalized between 0 and 1, thus no scaling and offset parameters were required. In order to keep the model simple, it does not contain glutamine production, the initial glutamine concentration was arbitrarily set to 1. While this does not permit conclusions about absolute indigoidine synthesis rates, comparison of rates between the individual conditions is possible.

Framework

Parameters have to be estimated from experimental data. In order to implement our mathematical model and the wetlab data, we used an open-source software package allowing for comprehensive analysis (D2D Software). With this framework, we were able to calibrate the model and perform robust parameter estimations

Results

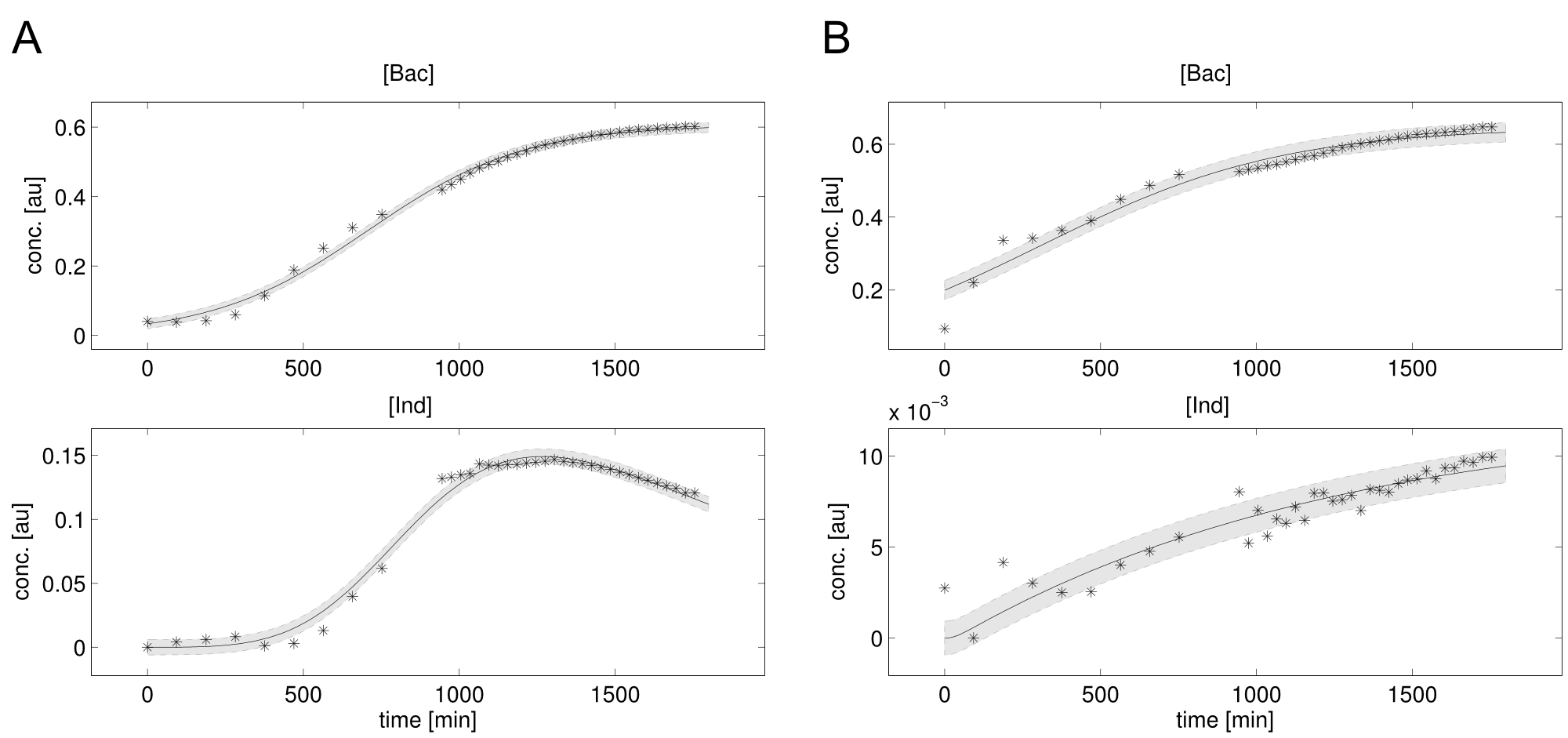

We received experimental data from the indigoidine team, who wanted to compare indigoidine synthesis rates between various T domains and PPTases. The model described above was thus fitted individually to each T domain / PPTase combination and simultaneously to all replicates. The data sets could be grouped into two types, those with a significant indigoidine production and those without. Although both types of data sets resulted in seemingly good fits (Fig. 4), identifiability analysis using a profile likelihood exploiting approach

Our mathematical model was able to describe most of our experimental data and was in those cases structurally and practically fully identifiable. We thus challenged the model to deduce additional facts on indigoidine synthesis. First, we had a look at the parameters that were estimated to describe our experimental data sets. For each parameter estimate, the lower boundary was set to 1e-5 and the upper boundary was set to 1e+5. Initial guesses for parameters during parameter estimations were generated via latin hypercube sampling to ensure broad coverage of all regions in the high-dimensional parameter space (http://www.jstor.org/stable/2346140). Nevertheless, some parameters exhibited broad variation among the best fits of the different data sets while other parameters were estimated in a narrow range (Fig. XXX).

Interestingly, the bacterial growth rate beta and the maximum growth capacity Bacmax were very consistent. The parameters ksyn, kdim and kdegi contributed directly to indogoidine synthesis as it can be inferred from the above mentioned equations \eqref{glu}, \eqref{cglu} and \eqref{ind}. The synthesis rate ksyn characterizes the cyclization of glutamine. The dimerization rate kdim reflects how two cyclized glutamine molecules form one indgoidine molecule. As such, ksyn and kdim represent the efficiency of the T domain of indC. The degradation rate of indigoidine, kdegi, should be independent from the domain structure of the indigoidine synthetase as the stability of the peptide is not affected by the T domains or the PPTases that were tested. The rate did not vary widely and the diverse data sets could still be explained by the mathematical model. At first glance, kdegi seemed less important for our experimentally assessed conditions. To further investigate the role of kdegi for indigoidine production kinetics, we systematically varied this parameter and compared simulation results. The synthesis of indigoidine was clearly affected by variation of kdegi (Fig. 7). The [Ind] trajectory collapsed more than 3-fold increase of the degradation rate. On the contrary, improved peptide stability could yield much more indigoidine. For very low degradation rates (i.e. kdegi < 1e-3), synthesis would not even saturate within the observed time frame.

Sensitivity analysis for optimized indigoidine production

To perceive the role of kdegi for indigoidine synthesis, we have varied the parameter over a broad range and observed qualitatively distinct model trajectories. For a more quantitative understanding of how indigoidine yield changes with altering parameters of the system, we conducted a sensitivity analysis (REVIEW NEEDED). Therefore, we first defined the variable IntInd, the integrated indigoidine reflecting production yield. The change of the indigoidine concentration with time is determined by the ODE (4) and its integral with time can be depicted as the area under the [Ind] curve, i.e. the amount of indigoidine produced by the bacteria with time. Now we were interested in the change of IntInd with the change of the different parameters of our system. Mathematically, this is expressed as the so called sensitivity $\frac{\partial \mathrm{X}}{\partial \mathrm{p}}$, with X as our variable of interest (IntInd) and p as the parameter (beta, Bacmax, ksyn, kdim or kdegi, respectively). This partial derivative provides a measure of how much X changes with the change of p or how sensitive X is against small variations in p. Sensitivities can be scaled with the actual values of X and the respective p to fall in the range from -1 to +1. The higher the absolute value of the sensitivity, the more important is the parameter for the variable. A positive sensitivity means positive impact of the parameter on the variable whereas a sensitivity < 0 indicates reduction of X for subtle decrease in p. We utilised our mathematical model and computed the sensitivities of IntInd against the change of all five kinetic parameters of our system and scaled them accordingly. The analysis confirmed that the kdegi was the only parameter of the system that exhibited a negative impact on the indigoidine production (Tab. 1). Slight increase of all the other parameters also augmented additional yield.

Sensitivity analysis for native_sfp:| Parameter | $$\left.\mathrm{[Bac]}\right|_{t=0}$$ | kdegi | kdim | beta | ksyn | Bacmax |

|---|---|---|---|---|---|---|

| $$\frac{\partial\int\!\mathrm{Ind}\,\mathrm{d}t}{\partial p}$$ | 0.784 | -0.7024 | 0.5117 | 0.3338 | 0.2919 | 0.1036 |

The initial concentration of bacteria represented the most crucial parameter for indigoidine production, which was intuitive since the amount of produced indigoidine depends on the amount of bacteria in culture that synthesise the peptide. The parameter kdegi exhibited a high impact on IntInd but did not vary so much among the experimental conditions. One would assume that the half-life of the peptide is not affected by different T domains or PPTases. Possibly, the arrangement of modules influences peptide stability as inter modular communication is a precondition for robust peptide assembly (REFERENCE). This links the peptide synthesis optimisation to our module shuffling project where modules of different hosts were combined for custom peptide synthesis. Indigoidine yield was also sensitive against small variations in beta and Bacmax. Culture conditions could be improved and metabolically more active strains could be chosen to further optimize performance in this respect. The parameters ksyn and kdim also determine peptide production.

The question is whether those rates could be altered by engineering the NRPS to advanced performance. To answer this question, we performed a multiple regression analysis (Fig. XXX+2). We regressed the alignment score of the synthetic T domains of the indigoidine synthase with the rates from the respective best fit. The score was calculated (http://www.ebi.ac.uk/Tools/msa/clustalw2/) by pairwise multiple sequence alignment of the amino acid sequences of the synthetic T domains with the native T domain of the indigoidine synthase as a template. The parameter values were obtained from parameter estimations of our mathematical model that has been calibrated with experimental data as described above.

"

"