Team:Imperial College/MAPLE

From 2013.igem.org

| (40 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

{{:Team:Imperial_College/Templates:header}} | {{:Team:Imperial_College/Templates:header}} | ||

| + | |||

| + | [[File:Maplelogotext.jpg|center|300px]] | ||

| + | |||

| + | [[File:FlowGraphic.png|FlowGraphic.png|1000px]] | ||

| + | |||

<html> | <html> | ||

| + | |||

| + | <script src="http://www.synbiuk.org/igem/jquery.flexslider-min.js" type="text/javascript"></script> | ||

| + | |||

| + | <link rel="stylesheet" href="http://www.synbiuk.org/igem/flexslider.css"> | ||

| + | |||

<style type="text/css"> | <style type="text/css"> | ||

| - | + | @charset "UTF-8"; | |

| - | + | #james-bond { | |

| - | + | text-align: center; | |

} | } | ||

| - | + | #james-bond h1, | |

| - | + | #james-bond h2, | |

| - | + | #james-bond h3, | |

| + | #james-bond h4, | ||

| + | #james-bond h5, | ||

| + | #james-bond h6 { | ||

| + | border: none; | ||

| + | } | ||

| + | #james-bond .bond-row.middle { | ||

| + | height: 100px; | ||

| + | position: relative; | ||

| + | } | ||

| + | #james-bond .bond-row.middle div { | ||

| + | position: absolute; | ||

| + | z-index: -1; | ||

| + | } | ||

| + | #james-bond .bond-row.middle #connector-1 { | ||

| + | background-image: url('https://static.igem.org/mediawiki/2013/b/b5/ImperialConnectorLeft.png'); | ||

| + | width: 165px; | ||

| + | height: 150px; | ||

| + | left: 80px; | ||

| + | top: -50px; | ||

| + | } | ||

| + | #james-bond .bond-row.middle #connector-2 { | ||

| + | background-image: url('https://static.igem.org/mediawiki/2013/b/b5/ImperialConnectorLeft.png'); | ||

| + | width: 165px; | ||

| + | height: 150px; | ||

| + | left: 327px; | ||

| + | top: -67px; | ||

| + | -webkit-transform: rotate(-15deg); | ||

| + | /* Chrome, Safari 3.1+ */ | ||

| - | + | -moz-transform: rotate(-15deg); | |

| + | /* Firefox 3.5-15 */ | ||

| - | + | -ms-transform: rotate(-15deg); | |

| + | /* IE 9 */ | ||

| - | + | -o-transform: rotate(-15deg); | |

| + | /* Opera 10.50-12.00 */ | ||

| - | + | transform: rotate(-15deg); | |

| + | /* Firefox 16+, IE 10+, Opera 12.10+ */ | ||

| - | + | } | |

| + | #james-bond .bond-row.middle #connector-3 { | ||

| + | background-image: url('https://static.igem.org/mediawiki/2013/6/6a/ImperialConnectorRight.png'); | ||

| + | width: 165px; | ||

| + | height: 150px; | ||

| + | right: 327px; | ||

| + | top: -67px; | ||

| + | -webkit-transform: rotate(15deg); | ||

| + | /* Chrome, Safari 3.1+ */ | ||

| - | + | -moz-transform: rotate(15deg); | |

| - | + | /* Firefox 3.5-15 */ | |

| - | + | -ms-transform: rotate(15deg); | |

| + | /* IE 9 */ | ||

| - | + | -o-transform: rotate(15deg); | |

| - | + | /* Opera 10.50-12.00 */ | |

| - | + | ||

| - | + | transform: rotate(15deg); | |

| - | + | /* Firefox 16+, IE 10+, Opera 12.10+ */ | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | } | |

| - | </ | + | #james-bond .bond-row.middle #connector-4 { |

| - | < | + | background-image: url('https://static.igem.org/mediawiki/2013/6/6a/ImperialConnectorRight.png'); |

| - | + | width: 165px; | |

| - | + | height: 150px; | |

| + | right: 80px; | ||

| + | top: -50px; | ||

| + | } | ||

| + | #james-bond .box { | ||

| + | cursor: pointer; | ||

| + | position: relative; | ||

| + | background: #36a9e1; | ||

| + | border: 2px solid #2b88b5; | ||

| + | box-shadow: 0 1px 4px rgba(0, 0, 0, 0.3); | ||

| + | z-index: auto; | ||

| + | width: 160px; | ||

| + | height: 160px; | ||

| + | display: inline-block; | ||

| + | margin-right: 16px; | ||

| + | } | ||

| + | #james-bond .box:last-of-type { | ||

| + | margin-right: 0; | ||

| + | } | ||

| + | #james-bond .box img { | ||

| + | width: 100%; | ||

| + | height: 100%; | ||

| + | position: relative; | ||

| + | z-index: 5; | ||

| + | } | ||

| + | x#james-bond .box:hover img { | ||

| + | -webkit-filter: grayscale(100%); | ||

| + | -moz-filter: grayscale(100%); | ||

| + | -ms-filter: grayscale(100%); | ||

| + | -o-filter: grayscale(100%); | ||

| + | filter: grayscale(100%); | ||

| + | filter: url("data:image/svg+xml;utf8,<svg xmlns=\'http://www.w3.org/2000/svg\'><filter id=\'grayscale\'><feColorMatrix type=\'matrix\' values=\'0.3333 0.3333 0.3333 0 0 0.3333 0.3333 0.3333 0 0 0.3333 0.3333 0.3333 0 0 0 0 0 1 0\'/></filter></svg>#grayscale"); | ||

| + | filter: gray; | ||

| + | /* IE 6-9 */ | ||

| - | + | } | |

| - | + | #james-bond .box .box-content { | |

| - | + | box-shadow: 0 1px 4px rgba(0, 0, 0, 0.3); | |

| - | + | position: absolute; | |

| - | + | z-index: 50; | |

| + | background-color: rgba(255, 255, 255, 0.75); | ||

| + | display: inline-block; | ||

| + | margin: 10px; | ||

| + | padding: 5px; | ||

| + | width: auto; | ||

| + | max-width: 60%; | ||

| + | border-left: 5px solid #008AC3; | ||

| + | top: 0; | ||

| + | left: 0; | ||

| + | opacity: 0.75; | ||

| + | } | ||

| + | #james-bond .box .box-content.right { | ||

| + | left: auto; | ||

| + | right: 0; | ||

| + | } | ||

| + | #james-bond .box .box-content * { | ||

| + | margin: 0; | ||

| + | padding: 0; | ||

| + | font-size: 100%; | ||

| + | } | ||

| + | #james-bond .box:hover:before, | ||

| + | #james-bond .box:hover:after { | ||

| + | -webkit-transition: all 300ms ease; | ||

| + | -moz-transition: all 300ms ease; | ||

| + | -ms-transition: all 300ms ease; | ||

| + | -o-transition: all 300ms ease; | ||

| + | transition: all 300ms ease; | ||

| + | } | ||

| + | #james-bond .box.right:after, | ||

| + | #james-bond .box.right:before { | ||

| + | border: solid transparent; | ||

| + | content: " "; | ||

| + | height: 0; | ||

| + | width: 0; | ||

| + | position: absolute; | ||

| + | pointer-events: none; | ||

| + | left: 75%; | ||

| + | opacity: 0; | ||

| + | } | ||

| + | #james-bond .box.right:hover:after, | ||

| + | #james-bond .box.right:hover:before { | ||

| + | left: 100%; | ||

| + | opacity: 1; | ||

| + | z-index: 2; | ||

| + | } | ||

| + | #james-bond .box.right:after { | ||

| + | border-color: rgba(54, 169, 225, 0); | ||

| + | border-left-color: #36a9e1; | ||

| + | border-width: 30px; | ||

| + | top: 50%; | ||

| + | margin-top: -30px; | ||

| + | } | ||

| + | #james-bond .box.right:before { | ||

| + | border-color: rgba(43, 136, 181, 0); | ||

| + | border-left-color: #2b88b5; | ||

| + | border-width: 33px; | ||

| + | top: 50%; | ||

| + | margin-top: -33px; | ||

| + | } | ||

| + | #james-bond .box.left:after, | ||

| + | #james-bond .box.left:before { | ||

| + | border: solid transparent; | ||

| + | content: " "; | ||

| + | height: 0; | ||

| + | width: 0; | ||

| + | position: absolute; | ||

| + | pointer-events: none; | ||

| + | right: 75%; | ||

| + | opacity: 0; | ||

| + | } | ||

| + | #james-bond .box.left:hover:after, | ||

| + | #james-bond .box.left:hover:before { | ||

| + | right: 100%; | ||

| + | opacity: 1; | ||

| + | } | ||

| + | #james-bond .box.left:after { | ||

| + | border-color: rgba(54, 169, 225, 0); | ||

| + | border-right-color: #36a9e1; | ||

| + | border-width: 30px; | ||

| + | top: 50%; | ||

| + | margin-top: -30px; | ||

| + | } | ||

| + | #james-bond .box.left:before { | ||

| + | border-color: rgba(43, 136, 181, 0); | ||

| + | border-right-color: #2b88b5; | ||

| + | border-width: 33px; | ||

| + | top: 50%; | ||

| + | margin-top: -33px; | ||

| + | } | ||

| + | #james-bond .box.top:after, | ||

| + | #james-bond .box.top:before { | ||

| + | border: solid transparent; | ||

| + | content: " "; | ||

| + | height: 0; | ||

| + | width: 0; | ||

| + | position: absolute; | ||

| + | pointer-events: none; | ||

| + | bottom: 75%; | ||

| + | opacity: 0; | ||

| + | } | ||

| + | #james-bond .box.top:hover:after, | ||

| + | #james-bond .box.top:hover:before { | ||

| + | bottom: 100%; | ||

| + | opacity: 1; | ||

| + | } | ||

| + | #james-bond .box.top:after { | ||

| + | border-color: rgba(54, 169, 225, 0); | ||

| + | border-bottom-color: #36a9e1; | ||

| + | border-width: 30px; | ||

| + | left: 50%; | ||

| + | margin-left: -30px; | ||

| + | } | ||

| + | #james-bond .box.top:before { | ||

| + | border-color: rgba(43, 136, 181, 0); | ||

| + | border-bottom-color: #2b88b5; | ||

| + | border-width: 33px; | ||

| + | left: 50%; | ||

| + | margin-left: -33px; | ||

| + | } | ||

| + | #james-bond .box.bottom:after, | ||

| + | #james-bond .box.bottom:before { | ||

| + | border: solid transparent; | ||

| + | content: " "; | ||

| + | height: 0; | ||

| + | width: 0; | ||

| + | position: absolute; | ||

| + | pointer-events: none; | ||

| + | top: 75%; | ||

| + | opacity: 0; | ||

| + | } | ||

| + | #james-bond .box.bottom:hover:after, | ||

| + | #james-bond .box.bottom:hover:before { | ||

| + | top: 100%; | ||

| + | opacity: 1; | ||

| + | } | ||

| + | #james-bond .box.bottom:after { | ||

| + | border-color: rgba(54, 169, 225, 0); | ||

| + | border-top-color: #36a9e1; | ||

| + | border-width: 30px; | ||

| + | left: 50%; | ||

| + | margin-left: -30px; | ||

| + | } | ||

| + | #james-bond .box.bottom:before { | ||

| + | border-color: rgba(43, 136, 181, 0); | ||

| + | border-top-color: #2b88b5; | ||

| + | border-width: 33px; | ||

| + | left: 50%; | ||

| + | margin-left: -33px; | ||

| + | } | ||

| + | #james-bond .box .more-info { | ||

| + | -webkit-transition: all 300ms ease; | ||

| + | -moz-transition: all 300ms ease; | ||

| + | -ms-transition: all 300ms ease; | ||

| + | -o-transition: all 300ms ease; | ||

| + | transition: all 300ms ease; | ||

| + | box-shadow: 0 1px 4px rgba(0, 0, 0, 0.3); | ||

| + | background: #36a9e1; | ||

| + | /* Old browsers */ | ||

| - | + | background: -moz-linear-gradient(top, #36a9e1 0%, #0099e0 100%); | |

| - | + | /* FF3.6+ */ | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | background: -webkit-gradient(linear, left top, left bottom, color-stop(0%, #36a9e1), color-stop(100%, #0099e0)); | |

| - | + | /* Chrome,Safari4+ */ | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | background: -webkit-linear-gradient(top, #36a9e1 0%, #0099e0 100%); | |

| + | /* Chrome10+,Safari5.1+ */ | ||

| - | + | background: -o-linear-gradient(top, #36a9e1 0%, #0099e0 100%); | |

| + | /* Opera 11.10+ */ | ||

| - | + | background: -ms-linear-gradient(top, #36a9e1 0%, #0099e0 100%); | |

| + | /* IE10+ */ | ||

| - | + | background: linear-gradient(to bottom, #36a9e1 0%, #0099e0 100%); | |

| - | + | /* W3C */ | |

| - | + | filter: progid:dximagetransform.microsoft.gradient(startColorstr='#36a9e1', endColorstr='#0099e0', GradientType=0); | |

| + | /* IE6-9 */ | ||

| + | padding: 10px; | ||

| + | text-align: justify; | ||

| + | cursor: auto; | ||

| + | border: 2px solid #2b88b5; | ||

| + | color: white; | ||

| + | opacity: 0; | ||

| + | overflow: hidden; | ||

| + | position: absolute; | ||

| + | visibility: hidden; | ||

| + | } | ||

| + | #james-bond .box:hover .more-info { | ||

| + | z-index: 100; | ||

| + | opacity: 1; | ||

| + | visibility: visible; | ||

| + | } | ||

| + | #james-bond .box#waste-issue { | ||

| + | width: 680px; | ||

| + | height: 402px; | ||

| + | } | ||

| + | #james-bond .box#waste-issue .box-content * { | ||

| + | margin: 0; | ||

| + | padding: 0; | ||

| + | font-size: 150%; | ||

| + | } | ||

| + | #xjames-bond .box#waste-issue .more-info { | ||

| + | top: 380px; | ||

| + | max-height: 0; | ||

| + | left: -150px; | ||

| + | width: 900px; | ||

| + | } | ||

| + | #xjames-bond .box#waste-issue:hover .more-info { | ||

| + | max-height: 500px; | ||

| + | } | ||

| + | #james-bond .box#landfill .more-info { | ||

| + | bottom: 214px; | ||

| + | width: 664px; | ||

| + | max-height: 0; | ||

| + | left: 104px; | ||

| + | } | ||

| + | #james-bond .box#landfill:hover .more-info { | ||

| + | max-height: 670px; | ||

| + | width: 660px; | ||

| + | } | ||

| + | #james-bond .box#incineration .more-info { | ||

| + | max-height: 0; | ||

| + | width: 660px; | ||

| + | left: -78px; | ||

| + | bottom: 214px | ||

| + | |||

| + | |||

| + | |||

| + | } | ||

| + | #james-bond .box#incineration:hover .more-info { | ||

| + | max-height: 500px; | ||

| + | } | ||

| + | #james-bond .box#gasification .more-info { | ||

| + | max-height: 0; | ||

| + | width: 660px; | ||

| + | bottom: 214px; | ||

| + | left: -262px; | ||

| + | } | ||

| + | #james-bond .box#gasification:hover .more-info { | ||

| + | max-height: 500px; | ||

| + | } | ||

| + | #james-bond .box#recycle .more-info { | ||

| + | left: -444px; | ||

| + | bottom: 214px; | ||

| + | max-height: 0; | ||

| + | width: 660px; | ||

| + | } | ||

| + | #james-bond .box#recycle:hover .more-info { | ||

| + | max-height: 670px; | ||

| + | } | ||

| + | |||

| + | #james-bond .box#home .more-info { | ||

| + | left: -627px; | ||

| + | bottom: 214px; | ||

| + | max-height: 0; | ||

| + | width: 660px; | ||

| + | } | ||

| + | #james-bond .box#home:hover .more-info { | ||

| + | max-height: 670px; | ||

| + | } | ||

| + | |||

| + | </style> | ||

| + | <p>We envision our M.A.P.L.E. system will develop across multiple scales as depicted on the graphic. The scales do not reflect temporal or geographic distribution of the technology.</p> | ||

| + | <br> | ||

| + | |||

| + | |||

| + | <h2>M.A.P.L.E. transforming waste into bioplastics</h2> | ||

| + | |||

| + | <h3>Product review, 11/10/2043</h3> | ||

| + | |||

| + | <p>M.A.P.L.E. (Modular And Plastic Looping <i>E.coli</i>) is the only range of appliances which run on rubbish and biologically transform it into new 3D printed, bioplastic objects. Since its launch in 2023, this technology has been deemed the ultimate in up-cycling and has played a major role in creating the greener and more sustainable world which we live in today. Over the years M.A.P.L.E. has been implemented in different ways, however, each device is solar-powered and comprised of a UV lamp to sterilise the waste, a shredder to mechanically break-up the rubbish, a bioreactor containing the engineered plastic-recycling bacteria and a 3D printer. This innovation has given people the freedom to design and print objects that are specifically tailored to their needs. The plastics produced are biocompatible as well as strong and durable. When they have fulfilled their purpose they can simply be fed back into the device and printed into something else.</br></p> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | <script type="text/javascript"> | ||

| + | $(function(){ | ||

| + | SyntaxHighlighter.all(); | ||

| + | }); | ||

| + | $(window).load(function(){ | ||

| + | $('.flexslider').flexslider({ | ||

| + | animation: "slide", | ||

| + | start: function(slider){ | ||

| + | $('body').removeClass('loading'); | ||

| + | } | ||

| + | }); | ||

| + | }); | ||

| + | </script> | ||

| + | |||

| + | <div id="james-bond"> | ||

| + | <div class="bond-row top"> | ||

| + | <div class="box xbottom" id="waste-issue"> | ||

| + | <div class="flexslider"> | ||

| + | <ul class="slides"> | ||

| + | <li> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/9/9c/Maple_comm.png" /> | ||

| + | </li> | ||

| + | <li> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/a/a7/3D_Maple_comm.png"/> | ||

| + | </li> | ||

| + | <li> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/5/51/Maple_mobile.png" /> | ||

| + | </li> | ||

| + | <li> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/1/13/Maple_house.png" /></li> | ||

| + | </ul> | ||

| + | </div> | ||

| + | <div class="xmore-info"> | ||

| + | |||

| + | </div> | ||

| + | </div> | ||

| + | </div> | ||

| + | |||

| + | <div style="height:50px;"> | ||

| + | |||

| + | </div> | ||

| + | |||

| + | <div class="bond-row bottom"> | ||

| + | <div class="box top" id="landfill"> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/7/7e/Maplebioreactors.png"> | ||

| + | <div class="box-contentx"> | ||

| + | |||

| + | </div> | ||

| + | <div class="more-info"> | ||

| + | <p>The vision of M.A.P.L.E. began in 2013 with the Plasticity project at Imperial College London. The team were driven to address the issues of the accumulation of the world’s waste and the need for renewable resources to produce materials, created by the consumerist, disposable culture of the past. Their work demonstrated how bacteria could be engineered to break down non-recyclable waste into its constitutive parts and reassemble the organic monomers into the bioplastic, polyhydroxybutyrate, which could also be biologically recycled.</p> | ||

| + | </div> | ||

| + | </div> | ||

| + | <div class="box top" id="incineration"> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/9/94/Industrialmaple.png"> | ||

| + | <div class="box-contentx"> | ||

| + | |||

| + | </div> | ||

| + | <div class="more-info"> | ||

| + | <p>It took 5 years for the system to be optimised and implemented at an industrial scale, producing bioplastic in huge bioreactors situated at existing recovery plants. Instead of sending non-recyclable mixed waste for incineration, it was immediately fed into the Plasticity bioreactors. This enabled large-scale production of bioplastic, supplying multiple manufacturers with material for processing.</p> | ||

| + | </div> | ||

| + | </div> | ||

| + | <div class="box top" id="gasification"> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/4/4f/Communitymaple.png"> | ||

| + | <div class="box-contentx"> | ||

| + | |||

| + | </div> | ||

| + | <div class="more-info"> | ||

| + | <p>The progression of technology enabled this system to be scaled down and address the issues on a local scale. The first M.A.P.L.E. device was installed on campus at Imperial College in 2023 and soon after could be found in close communities across the globe. This biorecycling, 3D printing tower operates by recording the mass and type of material waste deposited by each user. When a given user has collected enough rubbish to make their desired object, they send their CAD design to M.A.P.L.E. and watch in awe as it is printed out for them.</p> | ||

| + | </div> | ||

| + | </div> | ||

| + | <div class="box top" id="recycle"> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/6/6d/Bikemaple.png"> | ||

| + | <div class="box-contentx"> | ||

| + | |||

| + | </div> | ||

| + | <div class="more-info"> | ||

| + | <p>The idea of people using the rubbish they generate directly as a feedstock for manufacturing became very popular. Soon people were starting up their own businesses, buying rubbish from others and selling on the goods they had printed. To make life easier for these people, the next incarnation of M.A.P.L.E. was mobile, enabling traders to travel large distances to make sales.</p> | ||

| + | |||

| + | </div> | ||

| + | </div> | ||

| + | |||

| + | <div class="box top" id="home"> | ||

| + | <img src="https://static.igem.org/mediawiki/2013/4/40/Homemaple.png"> | ||

| + | <div class="box-contentx"> | ||

| + | |||

| + | </div> | ||

| + | <div class="more-info"> | ||

| + | <p>The latest M.A.P.L.E. device has been scaled down to fit onto your desk. This appliance is ideal for design and technology enthusiasts, who wish to create their own beautiful bioplastic objects, from household waste, in the comfort of their own homes.</p> | ||

| + | |||

| + | </div> | ||

| + | </div> | ||

| + | |||

| + | |||

| + | </div> | ||

| + | </div> | ||

| + | <br><br> | ||

| + | Take a look at our open source Community M.A.P.L.E. bin design <a href="https://static.igem.org/mediawiki/2013/8/88/MAPLE_With_STL2.zip">here</a>. | ||

| + | </html> | ||

{{:Team:Imperial_College/Templates:footer}} | {{:Team:Imperial_College/Templates:footer}} | ||

Latest revision as of 22:42, 28 October 2013

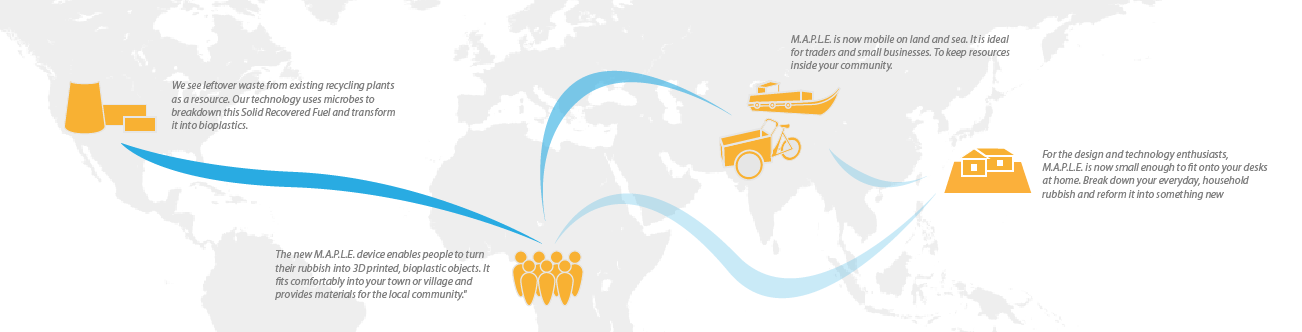

We envision our M.A.P.L.E. system will develop across multiple scales as depicted on the graphic. The scales do not reflect temporal or geographic distribution of the technology.

M.A.P.L.E. transforming waste into bioplastics

Product review, 11/10/2043

M.A.P.L.E. (Modular And Plastic Looping E.coli) is the only range of appliances which run on rubbish and biologically transform it into new 3D printed, bioplastic objects. Since its launch in 2023, this technology has been deemed the ultimate in up-cycling and has played a major role in creating the greener and more sustainable world which we live in today. Over the years M.A.P.L.E. has been implemented in different ways, however, each device is solar-powered and comprised of a UV lamp to sterilise the waste, a shredder to mechanically break-up the rubbish, a bioreactor containing the engineered plastic-recycling bacteria and a 3D printer. This innovation has given people the freedom to design and print objects that are specifically tailored to their needs. The plastics produced are biocompatible as well as strong and durable. When they have fulfilled their purpose they can simply be fed back into the device and printed into something else.

The vision of M.A.P.L.E. began in 2013 with the Plasticity project at Imperial College London. The team were driven to address the issues of the accumulation of the world’s waste and the need for renewable resources to produce materials, created by the consumerist, disposable culture of the past. Their work demonstrated how bacteria could be engineered to break down non-recyclable waste into its constitutive parts and reassemble the organic monomers into the bioplastic, polyhydroxybutyrate, which could also be biologically recycled.

It took 5 years for the system to be optimised and implemented at an industrial scale, producing bioplastic in huge bioreactors situated at existing recovery plants. Instead of sending non-recyclable mixed waste for incineration, it was immediately fed into the Plasticity bioreactors. This enabled large-scale production of bioplastic, supplying multiple manufacturers with material for processing.

The progression of technology enabled this system to be scaled down and address the issues on a local scale. The first M.A.P.L.E. device was installed on campus at Imperial College in 2023 and soon after could be found in close communities across the globe. This biorecycling, 3D printing tower operates by recording the mass and type of material waste deposited by each user. When a given user has collected enough rubbish to make their desired object, they send their CAD design to M.A.P.L.E. and watch in awe as it is printed out for them.

The idea of people using the rubbish they generate directly as a feedstock for manufacturing became very popular. Soon people were starting up their own businesses, buying rubbish from others and selling on the goods they had printed. To make life easier for these people, the next incarnation of M.A.P.L.E. was mobile, enabling traders to travel large distances to make sales.

The latest M.A.P.L.E. device has been scaled down to fit onto your desk. This appliance is ideal for design and technology enthusiasts, who wish to create their own beautiful bioplastic objects, from household waste, in the comfort of their own homes.

Take a look at our open source Community M.A.P.L.E. bin design here.

"

"