Team:Gaston Day School/Project

From 2013.igem.org

Overall Project

|

Serious health problems arise throughout the world due to the common water contaminants, heavy metals. The Agency for Toxic Substances and Disease registry released a Priority List of Hazardous Substances (ASTDR) of which heavy metals accounted for almost half of the top 10 substances. These substances can ultimately cause cancer along with other symptoms in affected systems like the lungs, blood, digestive system, and nervous system. Therefore, our 2012 team constructed a set of sensors that detect heavy metal contaminants in water. Among our Arsenic, Lead and Cadmium Sensors, we decided to improve the sensitivity of the Cadmium Sensor to provide more accurate and medically relevant levels of detection. This sensor previously paired a promoter responsive to Cadmium with GFP as a reporter. To improve this sensor, it was combined with an activator and a stronger promoter to amplify the signal as it reached the GFP reporter. Use of the detector could potentially save lives around the world through earlier detection of the contamination. The kit will include all necessary components for running the test and then decontaminating the resulting growth to prevent release of the engineered bacteria into the environment. We will include a very simple mechanism for killing or denaturing the bacteria in our detector kit – bleach. Bleach is highly effective at killing bacteria and is readily available to the average person. |

Project Details

We began building the improved Cadmium Sensor using NEB's BioBrick Construction Kit and created intermediate parts to form the final construct.

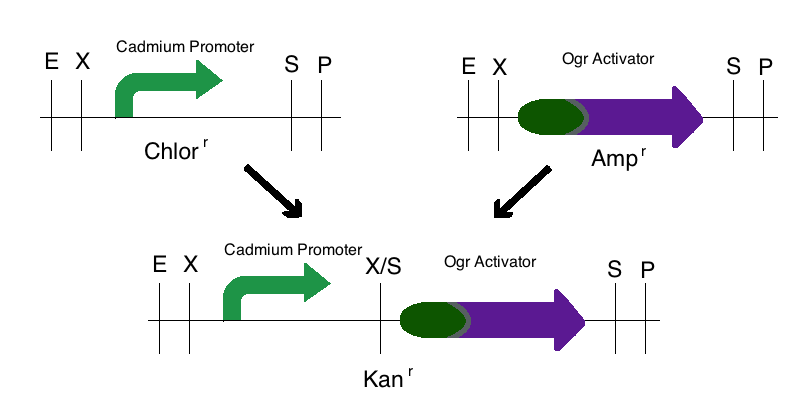

Step 1: We digested the promoter responsive to Cadmium (BBa_K174015) with EcoRI and SpeI and digested an activator (either ogr activator, BBa_I746350, or the delta activator, BBa_I746352) with XbaI and PstI. These parts were then ligated to a Kanamycin vector that was digested at EcoRI and PstI. This created two intermediate parts that were selectively grown on Kanamycin plates.

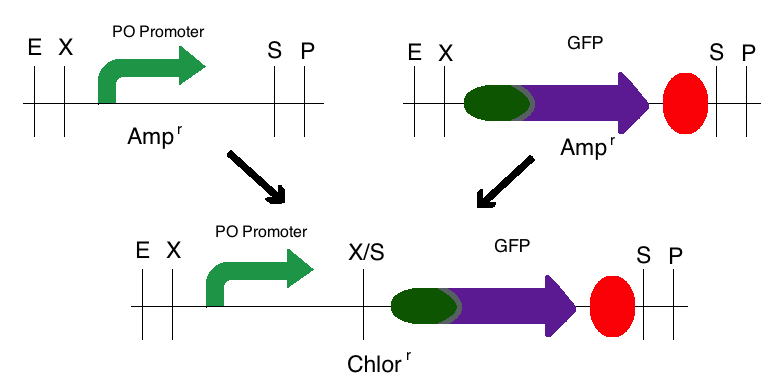

Step 2: The same process was used for the second intermediate part in which the PO Promoter (BBa_I746361) was the upstream part and the GFP plasmid (BBa_I13401) was the downstream part. However, these digested fragments were transferred to a Chloramphenicol vector. This produced one intermediate that was selectively grown on a Chloramphenicol plate.

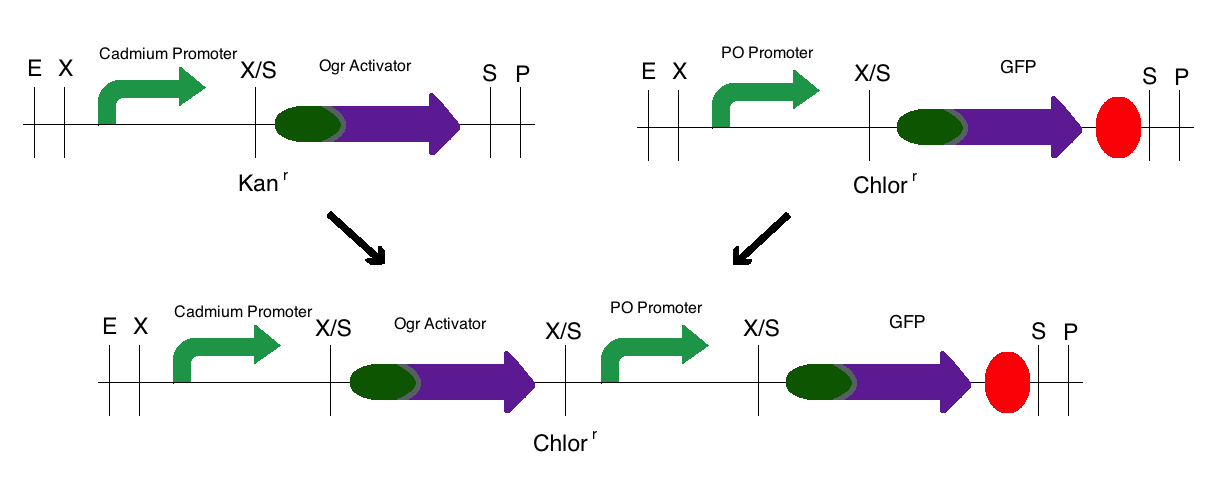

Step 3: The final construct was made in the same process where the intermediates of step 1 became upstream parts and the intermediate of step 2 became the downstream part. These parts were then mixed and ligated to the provided, linearized pSB1C3 plasmid. The resulting colonies were tested for responsive GFP production from the addition of Cadmium. Modeling of the process is shown below.

Note: The same methods were used for constructing a sensor with a delta activator instead of an ogr activator. The images below also model that part.

The Experiments

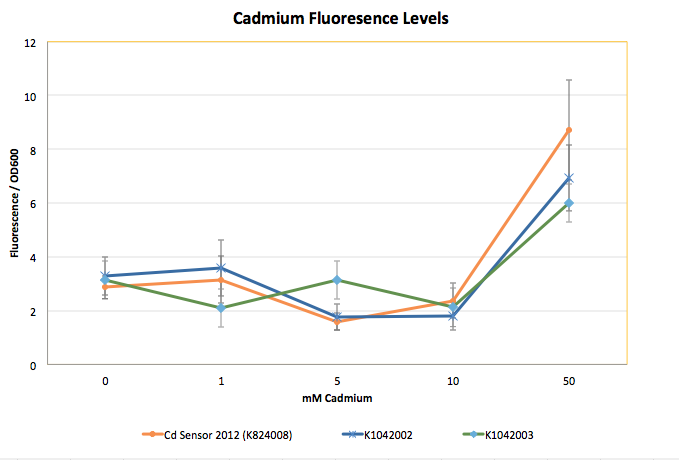

We tested out detectors (protocol can be found here) and measured the sensitivity using a spectrophotometer. We measured in Flu./OD which is the amount of fluorescence per OD (at 600nm). At first, we encountered many problems. We noticed that all of our dilutions, including the control were approximately the same. We realized that LB (Luria Broth, our growth medium) fluoresces naturally; hence, it masked the effects of the GFP. To solve this problem, we grew our bacteria in LB, centrifuged it, then resuspend in PBS (phosphate buffer solution). Lastly, our spectrophotometer still continued to show the same fluorescence reading for most samples except the control. We then realized that the readings had maxed. Serial dilutions were used to determine accurate measurements.

"

"