Team:Bielefeld-Germany/Project/MFC Efficiency

From 2013.igem.org

MFC Efficiency

Overview

- MFC efficiency calculation and feasibility study for better evaluation of the MFC.

Efficiency calculation

Feasibility study for MFC in sewage and waste treatment

To assess the usability of our MFC regarding potential applications, we considered a feasibility study and compared it to our results. It shows, that our currently achieved efficiencies have the potential for efficient energy production in real world applications.

The study

Feasibility study for the application of a Microbial Fuel Cell in sewage and waste treatment (AZ 26580-31)

Funded by the ‘Deutschen Bundesstiftung Umwelt – Osnabrück‘

Reporting period: 16.12.2008 – 31.08.2010

Author:

- Prof. Dr.-Ing. Michael Sievers1

- Dr. Ottmar Schläfer1

- Dipl.-Ing. Hinnerk Bormann1

- Dipl.-Ing. Michael Niedermeiser1

- Prof. Dr. Detlef Bahnemann2

- Dr. Ralf Dillert2

- 1 Clausthaler Umwelttechnik-Institut GmbH – CUTEC-Institut GmbH

- 2 Leibniz Universität Hannover

Summary

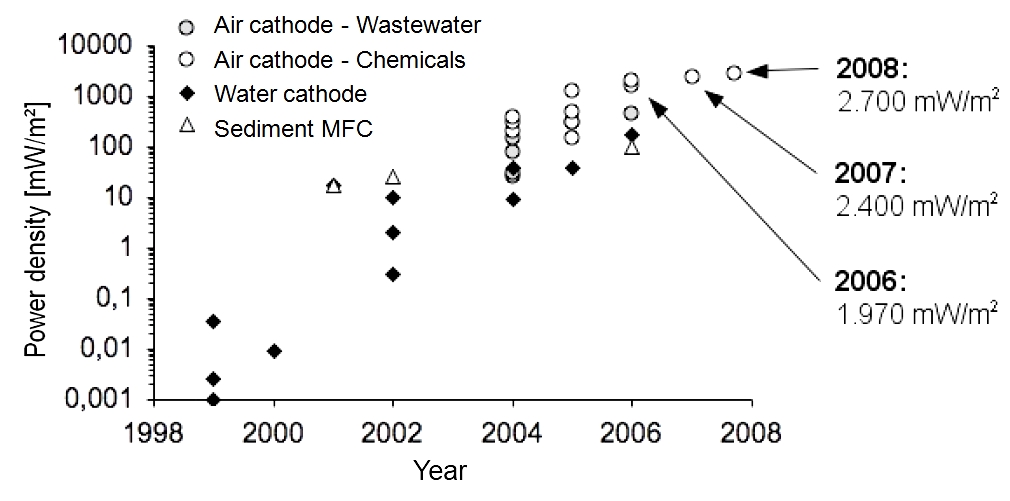

- Since the first investigations on mediatorless MFCs in 1999, the maximum power densities increased from 0.05 mW/m2 in 1999 to 2700 mW/m2 in 2008. Therefore, this feasibility study refers to a power density of 2 W/m2.

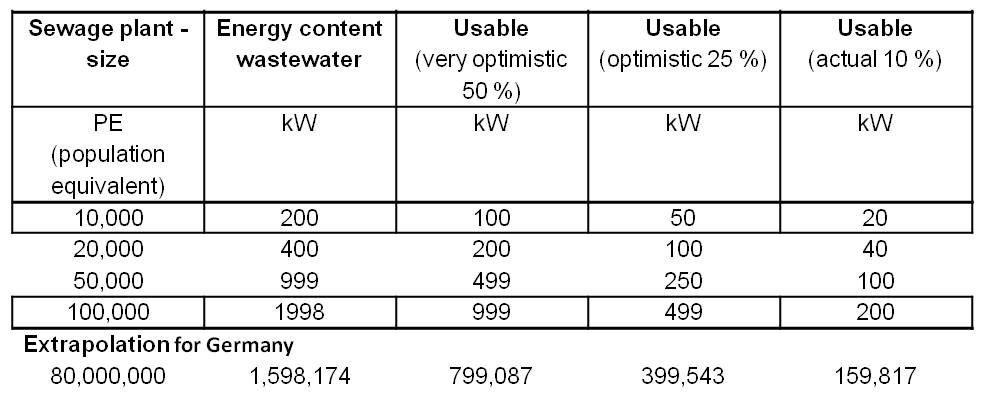

- An estimation of the power generation potential shows, that the usage of an MFC could produce around 20 kW for a 10,000 PE (population equivalent) sewage treatment plant. The integration of an MFC would generate an electricity production and saving potential, which provides the opportunity to enable nearly energy self-sufficient sewage treatment plants. This is based on a low cost production with low cost materials of the MFC. Especially electrode and membrane materials have to be cost-saving.

Previous development of the maximal achieved power densities with MFCs

- Since the first investigations on mediatorless MFCs in 1999, the maximum power densities increased. Figure 1 (Logan, 2008) shows the development of the power density from 0.05 mW/m2 in 1999 to 2700 mW/m2 in 2008.

- Pure chemicals (glucose or glycerol) are much better usable than organic wastewater components. Furthermore, the conductivity of the organic liquid is usually much higher. Consequently, power densities achieved with wastewater tests are lower. On closer examination of the cathode, we can observe a higher power density for air cathodes (wastewater treatment) in comparison to water cathodes (degradation of pure chemicals). Air cathodes are additionally fumigated.

Assessment of the potential for applications

- The energy content of waste water is about 20 W per population equivalent (PE). Therefore, a 10,000 PE plant could generate a power of 20 kW. Table 1 shows an overview of the electricity production potential for various wastewater treatment plant sizes with an extrapolation for 80 million people (Number of inhabitants of Germany). The energy content of the water is defined by the COD (Chemical oxygen demand). COD is commonly used to indirectly measure the amount of organic compounds in water.

- Table 2 overviews the electricity savings potential for various wastewater treatment plant sizes with an extrapolation for 80 million people (Number of inhabitants of Germany).

- In comparison, a fully optimized plant for 100,000 inhabitants has an average power consumption of 285 kW. The integration of an MFC would generate an electricity production potential and electricity savings potential of up to total 246 kW. Thus, the Microbial Fuel Cell provides the opportunity to enable energy self-sufficient sewage treatment plants.

Assessment of our Microbial Fuel Cell

- With our self-designed and constructed Microbial Fuel Cell we achieved a power density of 231 mW/m2. (Calculation of the power density). In contrast to the assumed power density for the feasibility study, which was 2000 mW/m2, we have still a ten times lower power density. That means the total electricity saving potential would be 25 kW, which shows a reduction for the required energy of 8% for a fully optimized sewage plant for 100,000 inhabitants with an average power consumption of 285 kW.

References

- Logan BE (2008): Microbial Fuel Cells. John Wiley & Sons Inc., New Jersey.

Contents |

"

"