Team:Imperial College/BioPlastic Recycling: PLA

From 2013.igem.org

Iain Bower (Talk | contribs) |

|||

| (5 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

{{:Team:Imperial_College/Templates:header}} | {{:Team:Imperial_College/Templates:header}} | ||

| - | + | __TOC__ | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

<h1>Recycling PLA</h1> | <h1>Recycling PLA</h1> | ||

<h3 id="overview">Overview</h3> | <h3 id="overview">Overview</h3> | ||

| + | </html> | ||

| + | |||

| + | <p> The bioplastic recycling module will look at closing the loop on bioplastics before they even begin to gain traction as a viable and more desirable plastic. We will be looking at degrading and synthesising polylactic acid (PLA) and poly-3-hydroxybutyrate (P3HB) using a fully biological system. The byproducts from the breakdown of our bioplastics will be separated then purified in order to allow them to be reused in industry</p> | ||

| + | |||

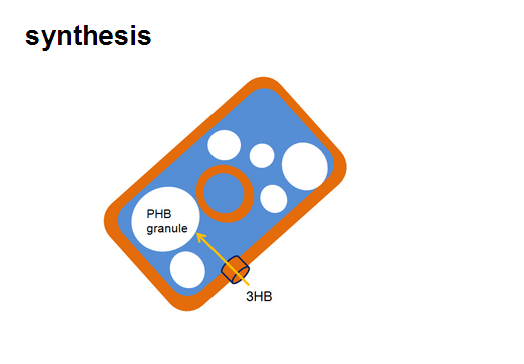

| + | [[File:SynthesisIC.jpg|thumbnail|left|600px|A diagrammatic representation of our P3HB recycling system]] | ||

| + | |||

| + | <p>Polylactic acid (PLA) is for the most part, a chemically derived aliphatic polyester. PLA can be moulded into a product and is used as a feedstock in 3D printing. The bioplastic has high strength and is a thermoplastic. It represents a growing market within the plastic industry, one which will inevitably require degradation at a recycling plant [http://naldc.nal.usda.gov/download/4048/PDF]. Currently only tentative pilot studies have been made towards engineering a biological mechanism to enhance degradation. We thus intend to use shredded PLA as a feedstock to breakdown this bioplastic, with enzymes capable of breaking both L- and D- enantiomeric bonds.</p> | ||

| + | |||

| + | |||

| + | |||

| + | <b>References</b> | ||

| + | <p>[1] http://naldc.nal.usda.gov/download/4048/PDF </p> | ||

<p></p> | <p></p> | ||

| Line 25: | Line 20: | ||

<h2 id="specification">Specification</h2> | <h2 id="specification">Specification</h2> | ||

| - | <p> </p> | + | <p>Our bacteria should be able to resist any potential toxicities that are associated with PLA or L-Lactic Acid</p> |

| + | <p>Our bacteria should be able to degrade PLA</p> | ||

<h2 id="modelling">Modelling</h2> | <h2 id="modelling">Modelling</h2> | ||

| Line 31: | Line 27: | ||

<p></p> | <p></p> | ||

| - | <h2 id=" | + | <h2 id="design">Design</h2> |

<p></p> | <p></p> | ||

| Line 44: | Line 40: | ||

<h2 id="safety">Safety</h2> | <h2 id="safety">Safety</h2> | ||

| + | |||

| + | MSDS sheets for relevant compounds e.g. L-Lactic acid | ||

| - | + | <html> | |

</div> | </div> | ||

</div> | </div> | ||

Latest revision as of 23:22, 23 September 2013

Contents |

Recycling PLA

Overview

</html>

The bioplastic recycling module will look at closing the loop on bioplastics before they even begin to gain traction as a viable and more desirable plastic. We will be looking at degrading and synthesising polylactic acid (PLA) and poly-3-hydroxybutyrate (P3HB) using a fully biological system. The byproducts from the breakdown of our bioplastics will be separated then purified in order to allow them to be reused in industry

Polylactic acid (PLA) is for the most part, a chemically derived aliphatic polyester. PLA can be moulded into a product and is used as a feedstock in 3D printing. The bioplastic has high strength and is a thermoplastic. It represents a growing market within the plastic industry, one which will inevitably require degradation at a recycling plant [http://naldc.nal.usda.gov/download/4048/PDF]. Currently only tentative pilot studies have been made towards engineering a biological mechanism to enhance degradation. We thus intend to use shredded PLA as a feedstock to breakdown this bioplastic, with enzymes capable of breaking both L- and D- enantiomeric bonds.

References

[1] http://naldc.nal.usda.gov/download/4048/PDF

Specification

Our bacteria should be able to resist any potential toxicities that are associated with PLA or L-Lactic Acid

Our bacteria should be able to degrade PLA

Modelling

Design

Results

Protocols

Safety

MSDS sheets for relevant compounds e.g. L-Lactic acid

"

"