Team:Edinburgh/Modeling/Waste treatment model

From 2013.igem.org

Hristianita (Talk | contribs) (Created page with "{{Team:Edinburgh/Menu}} {{Team_Edinburgh/Modelling_side_menu}} <div class='content'> Check back soon for updates. Thanks for visiting our site. </div> {{Team:Edinburgh/Foo...") |

Hristianita (Talk | contribs) |

||

| (2 intermediate revisions not shown) | |||

| Line 4: | Line 4: | ||

<div class='content'> | <div class='content'> | ||

| + | === Waste treatment model === | ||

| + | Once we had a whole cell model working on our chosen simulation platform, we had to extend it with a specific circuit module of the waste water treatment system the biology team was making. | ||

| - | + | Because the ethanol producing part of the project was far ahead of the metal binding one and there was much more data available for it, we decided to concentrate on modeling the ethanol production circuit. | |

| - | + | We added to the model two other variables c’ and p’ which represented the length of the extra DNA inserted and the amount of ethanol producing enzyme synthesized. The production of p’ and the replication of c’ also drew on system resources in a way similar to the rest of the proteins and DNA in the model. We then trained our system with parameters we received from the biology team – the length of the plasmid inserted into the cell, the average plasmid copy number, as well as the measured productivity (experimentally measured amount of p’) in a given nutrient environment. We used the plasmid length and copy to specify the total length of extra DNA inserted in the cell. We used the p’ number to determine the expressivity of the ethanol producing gene. | |

| + | |||

| + | In the end, we had a very simple whole cell model running on the platform, with an inserted very simple genetic circuit which simply produced one gene product at a given rate. We used this model to make some predictions about the growth rate of the modified cell in different nutrient environemnts. | ||

</div> | </div> | ||

{{Team:Edinburgh/Footer}} | {{Team:Edinburgh/Footer}} | ||

Latest revision as of 02:14, 5 October 2013

Waste treatment model

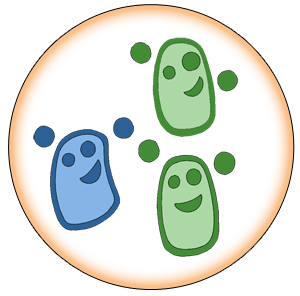

Once we had a whole cell model working on our chosen simulation platform, we had to extend it with a specific circuit module of the waste water treatment system the biology team was making.

Because the ethanol producing part of the project was far ahead of the metal binding one and there was much more data available for it, we decided to concentrate on modeling the ethanol production circuit.

We added to the model two other variables c’ and p’ which represented the length of the extra DNA inserted and the amount of ethanol producing enzyme synthesized. The production of p’ and the replication of c’ also drew on system resources in a way similar to the rest of the proteins and DNA in the model. We then trained our system with parameters we received from the biology team – the length of the plasmid inserted into the cell, the average plasmid copy number, as well as the measured productivity (experimentally measured amount of p’) in a given nutrient environment. We used the plasmid length and copy to specify the total length of extra DNA inserted in the cell. We used the p’ number to determine the expressivity of the ethanol producing gene.

In the end, we had a very simple whole cell model running on the platform, with an inserted very simple genetic circuit which simply produced one gene product at a given rate. We used this model to make some predictions about the growth rate of the modified cell in different nutrient environemnts.

|

| | | |

|

| This iGEM team has been funded by the MSD Scottish Life Sciences Fund. The opinions expressed by this iGEM team are those of the team members and do not necessarily represent those of MSD | |||||

"

"