Team:Edinburgh/Human Practices/Industries/Whisky

From 2013.igem.org

| (4 intermediate revisions not shown) | |||

| Line 7: | Line 7: | ||

| - | Dixit Dr. Chris French for Biotechnology 3 students of the University of Edinburgh: | + | Dixit Dr. Chris French for Biotechnology 3 students of the University of Edinburgh (circa 2013 A.D.): |

| Line 24: | Line 24: | ||

'''Figure 1.''' Glenkinchie distillery is located in the rural area of East Lothian. | '''Figure 1.''' Glenkinchie distillery is located in the rural area of East Lothian. | ||

| + | |||

| + | |||

Before the guided tour we have wandered around the site and admired the industrial architecture (Figure 2). | Before the guided tour we have wandered around the site and admired the industrial architecture (Figure 2). | ||

| Line 31: | Line 33: | ||

'''Figure 2.''' Aleksandra explores the premises of the Glenkinchie distillery. | '''Figure 2.''' Aleksandra explores the premises of the Glenkinchie distillery. | ||

| + | |||

| + | |||

During the guided tour we have learned how the whisky production process is performed. It struck us that the industry is deeply traditional (figure 3). Successful creation of the final product is dependent on years of experience of staff members and their dedication. | During the guided tour we have learned how the whisky production process is performed. It struck us that the industry is deeply traditional (figure 3). Successful creation of the final product is dependent on years of experience of staff members and their dedication. | ||

| Line 43: | Line 47: | ||

<h3> Waste treatment in the whisky industry </h3> | <h3> Waste treatment in the whisky industry </h3> | ||

| + | |||

While visiting the premises of the distillery we have tried to get as much information as possible on the way that waste products are being processed. Following a discussion with a staff member we have obtained following information: | While visiting the premises of the distillery we have tried to get as much information as possible on the way that waste products are being processed. Following a discussion with a staff member we have obtained following information: | ||

* Primary solid waste products which are left following first step of distillation are used as a pasture for pigs. Apparently the heavy metal ion content is too high to use those to feed poultry or cows. | * Primary solid waste products which are left following first step of distillation are used as a pasture for pigs. Apparently the heavy metal ion content is too high to use those to feed poultry or cows. | ||

* The liquid leftover from both stages of distillation is passed via the water treatment facility located on site (figure 4) | * The liquid leftover from both stages of distillation is passed via the water treatment facility located on site (figure 4) | ||

| + | |||

[[File:Whisky4.png]] | [[File:Whisky4.png]] | ||

| Line 52: | Line 58: | ||

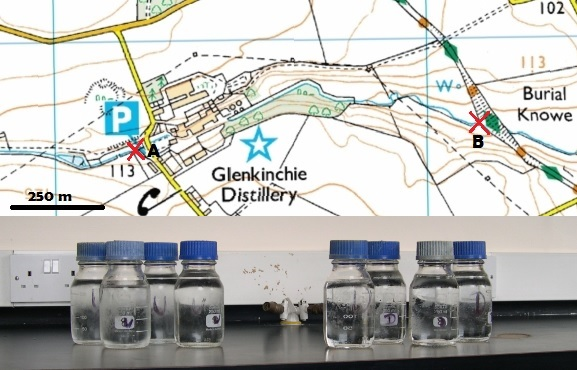

In order to evaluate the potential environmental impact on the environment we have collected water samples from upstream and downstream of the distillery (figure 5). | In order to evaluate the potential environmental impact on the environment we have collected water samples from upstream and downstream of the distillery (figure 5). | ||

| + | |||

| + | |||

| + | |||

| Line 61: | Line 70: | ||

| + | |||

| + | |||

| + | |||

[[File:Whisky6.png]] | [[File:Whisky6.png]] | ||

| Line 72: | Line 84: | ||

Primarily, the organic compounds that are currently fed into an anaerobic fermentor could be used to feed bacterial cells producing ethanol using our [[Team:Edinburgh/Project/Results/Bioethanol Results|fusion enzyme]]. This could generate a valuable product that could be distilled on site and potentially used as a fuel additive. There is no need to exchange any of the existing systems to achieve that – the only required thing would be to introduce different bacterial culture to already present bioreactor. | Primarily, the organic compounds that are currently fed into an anaerobic fermentor could be used to feed bacterial cells producing ethanol using our [[Team:Edinburgh/Project/Results/Bioethanol Results|fusion enzyme]]. This could generate a valuable product that could be distilled on site and potentially used as a fuel additive. There is no need to exchange any of the existing systems to achieve that – the only required thing would be to introduce different bacterial culture to already present bioreactor. | ||

| - | Additionally, we have noticed that within currently used system there is no dedicated method of heavy metal ion removal. Presence of those in distillery waste is substantial (Tripathi et al., 2011) and the amount that is released to the environment is affecting places where patent stills are used on a large scale such as India and Brazil . | + | Additionally, we have noticed that within currently used system there is no dedicated method of heavy metal ion removal. Presence of those in distillery waste is substantial (Tripathi et al., 2011) and the amount that is released to the environment is affecting places where patent stills are used on a large scale such as India and Brazil . The introduction of bacterial metal capture system downstream of the currently used devices would be beneficial to both environment and the industry itself that could gain additional revenues from selling isolated metals. |

| + | |||

| + | [https://2013.igem.org/Team:Edinburgh/Human_Practices/Industries/Whisky Back to top] | ||

<h2>References:</h2> | <h2>References:</h2> | ||

Latest revision as of 02:19, 5 October 2013

Contents |

Whisky industry and its importance in Scotland

Dixit Dr. Chris French for Biotechnology 3 students of the University of Edinburgh (circa 2013 A.D.):

Spirits such as whisky have a much higher alcohol concentration than beer, which is achieved by distillation. This is essentially a process of heating the liquid so that it forms a vapour phase enriched in ethanol (the more volatile component) and a liquid phase enriched in water. The alcohol-rich vapour is removed and condensed to give a liquid of higher alcohol content.

In the traditional process used to make malt whisky, the first step is to use malted barley to produce an unhopped beer of about 10% v/v alcohol. This is then distilled using copper pot stills in a batch process. Usually two stills in series are used. The beer is placed in the wash still and heated to produce an enriched fraction of 21% v/v alcohol called low wines. This is transferred to the spirit still, where it is further distilled to around 57% v/v alcohol. This raw spirit is then matured in used wine casks for several years (a minimum of three years in Scotland, but malt whiskies are matured for at least 3 years and often much longer), during which some compounds are absorbed into the wood and others extracted. Grain whiskies are made in a similar way, but some cheaper unmalted grain is added along with the malt.

'Scotch' whisky is a hugely valuable product, earning $5 billion in exports in 2006, a quarter of all food and drink exports from Britain. It has been said that the whisky maturing in bonded warehouses in Scotland is worth more than the gold in the vaults of the Bank of England.

Our visit to Glenkinchie distillery

A major part of our Human Practices work was to evaluate if the system that we have created would be applicable in the industry setting. In order to do that we have visited Glenkinchie distillery located just 20 miles outside of Edinburgh (Figure 1).

Figure 1. Glenkinchie distillery is located in the rural area of East Lothian.

Before the guided tour we have wandered around the site and admired the industrial architecture (Figure 2).

Figure 2. Aleksandra explores the premises of the Glenkinchie distillery.

During the guided tour we have learned how the whisky production process is performed. It struck us that the industry is deeply traditional (figure 3). Successful creation of the final product is dependent on years of experience of staff members and their dedication.

Figure 3. During final stages of distillation the initial effluent containing harmful methanol is separated from desired ethanol. This is performed manually using the lever combined with two separate collection vessels (left). A traditional batch process of whisky production in the Glenkinche distillery museum (right) – currently just the scale is larger the appearance of devices used barely changed.

Waste treatment in the whisky industry

While visiting the premises of the distillery we have tried to get as much information as possible on the way that waste products are being processed. Following a discussion with a staff member we have obtained following information:

- Primary solid waste products which are left following first step of distillation are used as a pasture for pigs. Apparently the heavy metal ion content is too high to use those to feed poultry or cows.

- The liquid leftover from both stages of distillation is passed via the water treatment facility located on site (figure 4)

Figure 4. Waste-water treatment plant located within the premises of Glenkinchie distillery. The water treatment is based first on an anaerobic fermentor which is followed by a set of coagulators. Following this treatment resulting liquid is poured into the stream that is passing the site.

In order to evaluate the potential environmental impact on the environment we have collected water samples from upstream and downstream of the distillery (figure 5).

Figure 5. Top: Water sampling points. A- upstream of the distillery, B- downstream of the distillery. Interestingly, the area from distillery to sampling point B was fenced what prevented us from obtaining a sample from a point located closer to the disposal site. Bottom: our water samples!

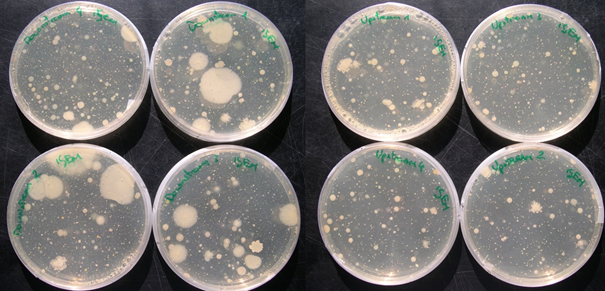

Water samples were plated out in order to establish any potential impact of the distillery on the microbiome of the stream (figure 6)

Figure 6. Downstream (left) and Upstream (right) plates. Slightly increased cell count of the downstream plates could be attributed to disposal of organic matter to the stream. However, the area surrounding sampling point could have potentially affected the result.

Is there a place for our system?

From our discussion and observation we have concluded that there is both place and need for the system that we want to create. We believe that within distillery industry there is a potential to apply both parts of our project, that is conversion of carbon waste to ethanol and metal ion capture.

Primarily, the organic compounds that are currently fed into an anaerobic fermentor could be used to feed bacterial cells producing ethanol using our fusion enzyme. This could generate a valuable product that could be distilled on site and potentially used as a fuel additive. There is no need to exchange any of the existing systems to achieve that – the only required thing would be to introduce different bacterial culture to already present bioreactor.

Additionally, we have noticed that within currently used system there is no dedicated method of heavy metal ion removal. Presence of those in distillery waste is substantial (Tripathi et al., 2011) and the amount that is released to the environment is affecting places where patent stills are used on a large scale such as India and Brazil . The introduction of bacterial metal capture system downstream of the currently used devices would be beneficial to both environment and the industry itself that could gain additional revenues from selling isolated metals.

References:

Tripathi, D., Tripathi, S., Tripathi, B. 2011. Implications of Secondary Treated Distillery Effluent Irrigation on Soil Cellulase and Urease Activities. Journal of Environmental Protection 2. 655- 661

|

| | | |

|

| This iGEM team has been funded by the MSD Scottish Life Sciences Fund. The opinions expressed by this iGEM team are those of the team members and do not necessarily represent those of MSD | |||||

"

"