Team:Imperial College/Applications

From 2013.igem.org

Iain Bower (Talk | contribs) |

|||

| (5 intermediate revisions not shown) | |||

| Line 3: | Line 3: | ||

<h1>Bioplastics have a bright future</h1> | <h1>Bioplastics have a bright future</h1> | ||

| - | <p>Bioplastics are made either directly by living things or from the products they make. They are usually more environmentally friendly than petrochemically derived plastics(1) and do not rely upon finite fossil fuels. Advances in how they are produced is allowing bioplastics with controllable physical properties to be produced(3) | + | <p>Bioplastics are made either directly by living things or from the products they make. They are usually more environmentally friendly than petrochemically derived plastics [http://www.hpa.org.uk/webc/HPAwebFile/HPAweb_C/1309969974126 (1)] and do not rely upon finite fossil fuels. Advances in how they are produced is allowing bioplastics with controllable physical properties to be produced [http://www.foe.co.uk/resource/briefings/safety_incinerator_ash.pdf (3)] enabling uses which mimic those of oil-based plastics. The properties of some bioplastics allow novel functions to be carried out. An exciting example of this is the production of biocompatible scaffolds which can be used in surgical treatments [http://www.bredl.org/pdf2/StopIncinerationBlowingSmoke.pdf (4)]. This combination of innovations leading to improved functions and the development of novel uses combined with environmental benefits over petrochemical plastics are just some of the reasons why bioplastics are expected to flourish commercially in the coming years [http://ije.oxfordjournals.org/content/29/3/391.full.pdf (5)]. Currently around 10% of the plastics market consists of bioplastics, with this predicted to increase to around 30% by 2020. This is a huge increase and represents significant commercial opportunities. The predicted production of such a large amount of material requires careful consideration of what we do once we have used the products produced, called end of life solutions. |

<br> | <br> | ||

| - | Poly-3-hydroxybutyrate(P3HB) and | + | Poly-3-hydroxybutyrate (P3HB) and poly(lactic Acid)(PLA) are both commonly used and well studied bioplastics. Currently several different companies produce each by a variety of methods [http://www.epa.gov/wastes/nonhaz/industrial/guide/ (9)]. </p> |

<h2>Poly-3-Hydroxybutyrate</h2> | <h2>Poly-3-Hydroxybutyrate</h2> | ||

| - | <p> | + | <p>P(3HB) is produced as an energy store in some bacteria. Commercially it is produced in bioreactors from sucrose and other sugars derived from plant biomass. P(3HB) can also be produced in the stems of plants, however this requires large inputs of fertiliser and large areas of land for crop growth. Interest in the production from the fermentation of organic waste materials is increasing. P(3HB) and related polymers are being investigated for uses in many things from food packaging to discount cards to replacements for current plastics. Extensive research is taking place into the properties of blends of different bioplastic polymers. |

</p> | </p> | ||

<h2>Polylactic acid</h2> | <h2>Polylactic acid</h2> | ||

| - | <p> | + | <p>Poly(lactic acid) production is usually a chemical process, building up the monomers of lactic acid or lactide. It can also be produced by certain organisms. Biological systems of PLA production are also possible. This is what our collaborators at Yale are working on. PLA already sees use in the packaging industry and plastic bottles. Future uses as with many ‘biodegradable’ plastics will expand to include tasks where increased durability is needed [http://ec.europa.eu/environment/waste/ (8)]. |

</p> | </p> | ||

<br> | <br> | ||

| Line 19: | Line 19: | ||

<h1>Bioplastic applications</h1> | <h1>Bioplastic applications</h1> | ||

| - | <p align="justify">Bioplastics, such as poly-3-hydroxybutyrate and | + | <p align="justify">Bioplastics, such as poly-3-hydroxybutyrate and poly(lactic acid) can be processed in very similar ways to petrochemical plastics such as injection moulding, extrusion and thermoforming. To improve their tensile strength, bioplastic polymers can be blended or electrospun with their co-polymers or with other polymers. These bioplastics can also be 3D printed with. |

| - | The most exciting property of these bioplastics is that they are very biocompatible, as they break down into monomers that are normally found in the body. They are, therefore, ideal for medical applications. Poly-3-hydroxybutyrate has been used to make devices such as surgical meshes, sutures, screws & plates for bone fixation, cardiovascular patches, nerve guides, periodontal membranes, wound dressings and microcapsules for drug delivery. [http://onlinelibrary.wiley.com/doi/10.1002/masy.201100237/abstract (11)][http://onlinelibrary.wiley.com/doi/10.1046/j.1469-7580.2003.00243.x/pdf (12)][http://maxwellsci.com/print/crjbs/(2)23-26.pdf (13)] | + | The most exciting property of these bioplastics is that they are very biocompatible, as they break down into monomers that are normally found in the body and environment. They are, therefore, ideal for medical applications. Poly-3-hydroxybutyrate has been used to make devices such as surgical meshes, sutures, screws & plates for bone fixation, cardiovascular patches, nerve guides, periodontal membranes, wound dressings and microcapsules for drug delivery. [http://onlinelibrary.wiley.com/doi/10.1002/masy.201100237/abstract (11)][http://onlinelibrary.wiley.com/doi/10.1046/j.1469-7580.2003.00243.x/pdf (12)][http://maxwellsci.com/print/crjbs/(2)23-26.pdf (13)] |

| - | [[File:Journal.pone.0035422.g003.png|centre|thumbnail|800px|<b>Figure from <i>Endothelial Differentiation of Human Stem Cells Seeded onto Electrospun Polyhydroxybutyrate/Polyhydroxybutyrate-Co-Hydroxyvalerate Fiber Mesh</i> [http://www.plosone.org/article/info%3Adoi/10.1371/journal.pone.0035422 (11)]. This shows a SEM micrograph of the | + | [[File:Journal.pone.0035422.g003.png|centre|thumbnail|800px|<b>Figure from <i>Endothelial Differentiation of Human Stem Cells Seeded onto Electrospun Polyhydroxybutyrate/Polyhydroxybutyrate-Co-Hydroxyvalerate Fiber Mesh</i> [http://www.plosone.org/article/info%3Adoi/10.1371/journal.pone.0035422 (11)]. This shows a SEM micrograph of the P(3HB)/PHB-co-PHV mesh fibre seeded with human stem cells. This work demonstrates how P(3HB) and other similar bioplastics are great materials for bioscaffolds, as they provide enhanced vascularisation for the developing tissue.</b>]] |

Bioplastics are certainly fantastic materials, with many desirable properties and possible applications. In the future we may rely on bioplastics for manufacturing every day objects, perhaps in the [[Team:Imperial_College/MAPLE|comfort of your own home]].</p> | Bioplastics are certainly fantastic materials, with many desirable properties and possible applications. In the future we may rely on bioplastics for manufacturing every day objects, perhaps in the [[Team:Imperial_College/MAPLE|comfort of your own home]].</p> | ||

| Line 28: | Line 28: | ||

<h4><p>First you need your plastic</p></h4> | <h4><p>First you need your plastic</p></h4> | ||

Here's how to make [https://static.igem.org/mediawiki/2013/d/d6/Homebrew.pdf Biolastic Homebrew]. Now extract and print. | Here's how to make [https://static.igem.org/mediawiki/2013/d/d6/Homebrew.pdf Biolastic Homebrew]. Now extract and print. | ||

| - | |||

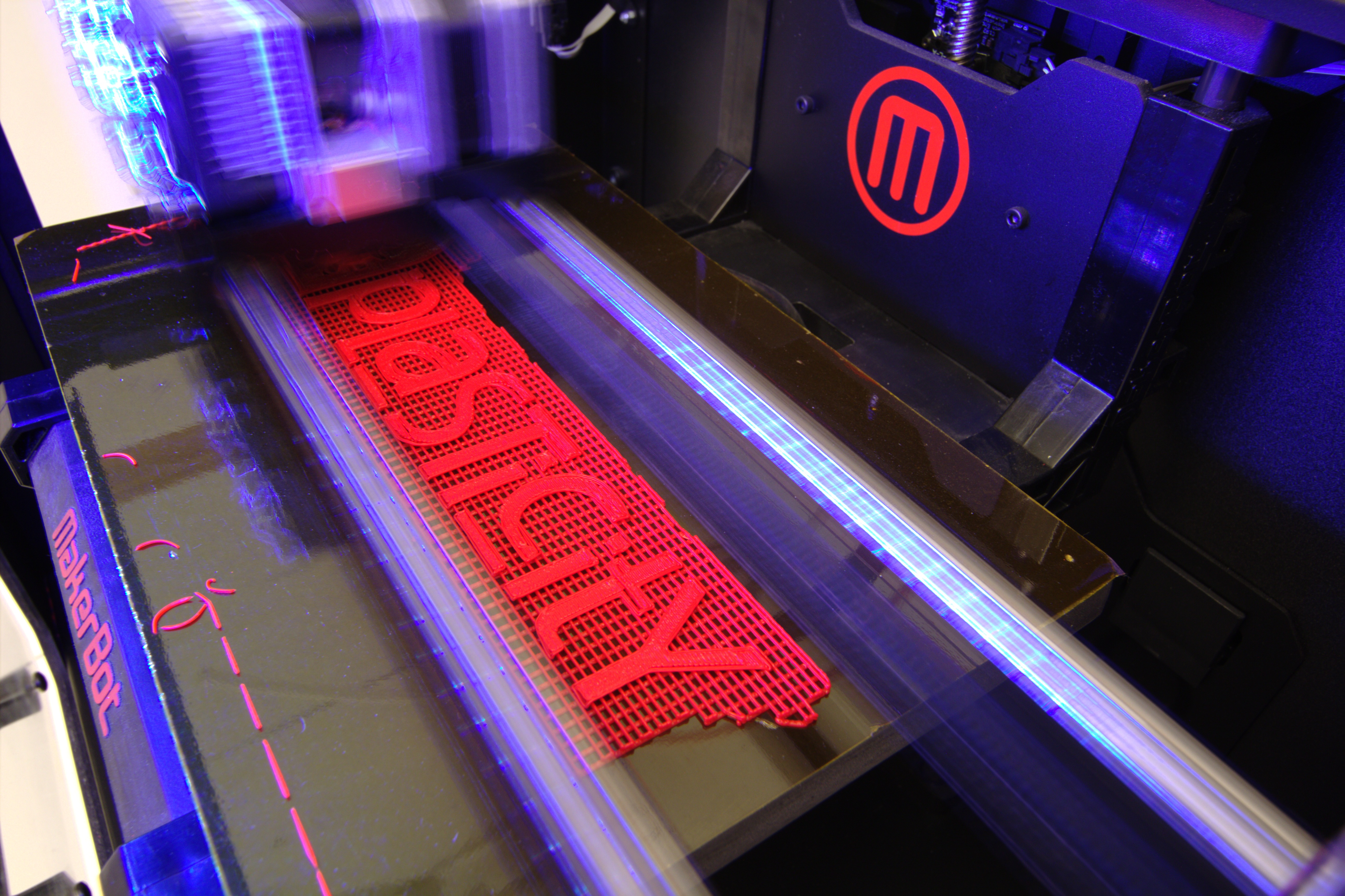

<center><b>Here is our team logo, printed in Bioplastic! CLICK ON IT!</b></center> | <center><b>Here is our team logo, printed in Bioplastic! CLICK ON IT!</b></center> | ||

| Line 34: | Line 33: | ||

<center><b>Here is our team logo, printed in Bioplastic! CLICK ON IT!</b></center> | <center><b>Here is our team logo, printed in Bioplastic! CLICK ON IT!</b></center> | ||

| - | <center><h3>In the future | + | <center><h3>In the future will you be able turn your household waste into this?</h3></center> |

| - | <center>[[Team:Imperial_College/MAPLE|See the future]] | + | <center>[[Team:Imperial_College/MAPLE|See the future]]</center> |

<h2>References</h2> | <h2>References</h2> | ||

Latest revision as of 08:33, 25 October 2013

Bioplastics have a bright future

Bioplastics are made either directly by living things or from the products they make. They are usually more environmentally friendly than petrochemically derived plastics [http://www.hpa.org.uk/webc/HPAwebFile/HPAweb_C/1309969974126 (1)] and do not rely upon finite fossil fuels. Advances in how they are produced is allowing bioplastics with controllable physical properties to be produced [http://www.foe.co.uk/resource/briefings/safety_incinerator_ash.pdf (3)] enabling uses which mimic those of oil-based plastics. The properties of some bioplastics allow novel functions to be carried out. An exciting example of this is the production of biocompatible scaffolds which can be used in surgical treatments [http://www.bredl.org/pdf2/StopIncinerationBlowingSmoke.pdf (4)]. This combination of innovations leading to improved functions and the development of novel uses combined with environmental benefits over petrochemical plastics are just some of the reasons why bioplastics are expected to flourish commercially in the coming years [http://ije.oxfordjournals.org/content/29/3/391.full.pdf (5)]. Currently around 10% of the plastics market consists of bioplastics, with this predicted to increase to around 30% by 2020. This is a huge increase and represents significant commercial opportunities. The predicted production of such a large amount of material requires careful consideration of what we do once we have used the products produced, called end of life solutions.

Poly-3-hydroxybutyrate (P3HB) and poly(lactic Acid)(PLA) are both commonly used and well studied bioplastics. Currently several different companies produce each by a variety of methods [http://www.epa.gov/wastes/nonhaz/industrial/guide/ (9)].

Poly-3-Hydroxybutyrate

P(3HB) is produced as an energy store in some bacteria. Commercially it is produced in bioreactors from sucrose and other sugars derived from plant biomass. P(3HB) can also be produced in the stems of plants, however this requires large inputs of fertiliser and large areas of land for crop growth. Interest in the production from the fermentation of organic waste materials is increasing. P(3HB) and related polymers are being investigated for uses in many things from food packaging to discount cards to replacements for current plastics. Extensive research is taking place into the properties of blends of different bioplastic polymers.

Polylactic acid

Poly(lactic acid) production is usually a chemical process, building up the monomers of lactic acid or lactide. It can also be produced by certain organisms. Biological systems of PLA production are also possible. This is what our collaborators at Yale are working on. PLA already sees use in the packaging industry and plastic bottles. Future uses as with many ‘biodegradable’ plastics will expand to include tasks where increased durability is needed [http://ec.europa.eu/environment/waste/ (8)].

Bioplastic applications

Bioplastics, such as poly-3-hydroxybutyrate and poly(lactic acid) can be processed in very similar ways to petrochemical plastics such as injection moulding, extrusion and thermoforming. To improve their tensile strength, bioplastic polymers can be blended or electrospun with their co-polymers or with other polymers. These bioplastics can also be 3D printed with. The most exciting property of these bioplastics is that they are very biocompatible, as they break down into monomers that are normally found in the body and environment. They are, therefore, ideal for medical applications. Poly-3-hydroxybutyrate has been used to make devices such as surgical meshes, sutures, screws & plates for bone fixation, cardiovascular patches, nerve guides, periodontal membranes, wound dressings and microcapsules for drug delivery. [http://onlinelibrary.wiley.com/doi/10.1002/masy.201100237/abstract (11)][http://onlinelibrary.wiley.com/doi/10.1046/j.1469-7580.2003.00243.x/pdf (12)][http://maxwellsci.com/print/crjbs/(2)23-26.pdf (13)]

First you need your plastic

Here's how to make Biolastic Homebrew. Now extract and print.

In the future will you be able turn your household waste into this?

References

- http://www.hpa.org.uk/webc/HPAwebFile/HPAweb_C/1309969974126

- http://www.plastics.ca/_files/file.php?fileid=filegXOOqaldWF&filename=file_files_Gasification2_Pop._Science_7_Aug._03.pdf

- http://www.foe.co.uk/resource/briefings/safety_incinerator_ash.pdf

- http://www.bredl.org/pdf2/StopIncinerationBlowingSmoke.pdf

- http://ije.oxfordjournals.org/content/29/3/391.full.pdf

- http://www.no-burn.org/downloads/Incinerators%20Trash%20Community%20Health.pdf

- http://www.sciencedirect.com/science/article/pii/S0961953407002322

- http://ec.europa.eu/environment/waste/

- http://www.epa.gov/wastes/nonhaz/industrial/guide/

- http://www.theguardian.com/environment/2013/sep/20/plastic-bags-symbol-waste-recycling/

- http://www.plosone.org/article/info%3Adoi/10.1371/journal.pone.0035422

- http://onlinelibrary.wiley.com/doi/10.1002/masy.201100237/abstract

- http://onlinelibrary.wiley.com/doi/10.1046/j.1469-7580.2003.00243.x/pdf

- http://maxwellsci.com/print/crjbs/(2)23-26.pdf

"

"