Team:Imperial College/Industrial Implementation

From 2013.igem.org

Margarita K (Talk | contribs) |

|||

| Line 61: | Line 61: | ||

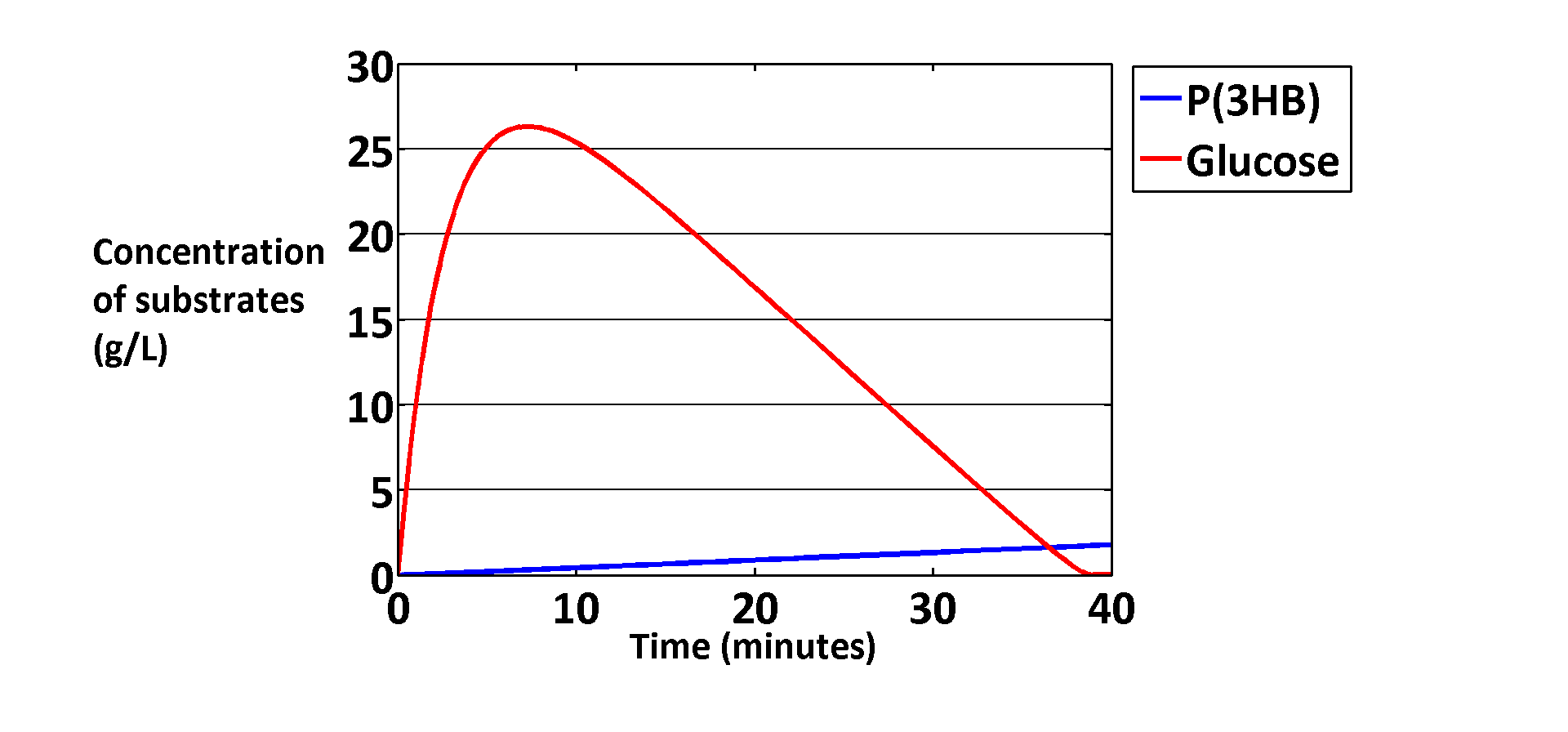

In our experimental results, we produced [https://2013.igem.org/Team:Imperial_College/PHB_production 2.48 g/L PHB on 3% glucose LB media, grown for 1 day]. Therefore, we calculate that 3% of the glucose is converted with this method. </p> | In our experimental results, we produced [https://2013.igem.org/Team:Imperial_College/PHB_production 2.48 g/L PHB on 3% glucose LB media, grown for 1 day]. Therefore, we calculate that 3% of the glucose is converted with this method. </p> | ||

<p>Our models predict similar conversion from glucose to PHB.</p> | <p>Our models predict similar conversion from glucose to PHB.</p> | ||

| - | + | [[File: Glucose efficiency.png|centre|800px|<b>Modelling of P(3HB) production from glucose</b> ]] | |

Revision as of 14:55, 23 October 2013

Contents |

Industrial Implementation

Summary

Mixed waste is particularly difficult to manage due to limitations in current technologies. We have identified solid recovered fuel (SRF), mainly composed of plastics and paper that cannot be recycled in existing recycling facilities, as our market niche. One objective of our technology is to build on current recycling infrastructure and make use of resourceful waste to produce bioplastics. Since the SRF, the feedstock of our engineered bacteria, is a burden to recycling companies, we can make profits through selling our products poly-3-hydroxybutyrate (P3HB) and ethylene glycol and charging the companies for sending SRF to us.

Products

Using mixed waste as a resource, our system has been designed to produce poly-3-hydroxybutyrate and ethylene glycol as commodities to be sold in industry.

P3HB is degraded by specialised microorganisms without releasing of toxic products or intermediates. It has a low water solubility [1] and medium-low water and CO2 permeability [2], as well as very good barrier properties that are ideal for packaging. This biopolymer also has a high degree of crystallinity, high melting temperature [3], and good tensile strength, making it comparable to one of the most common petroplastic isotactic polypropylene [3]. In addition, there are many processing methods for P3HB [4], such as injection molding and extrusion, which are required in manufacture of most plastic products. Although the impact strength is relatively weaker compared to petroplastics, P3HB nanocomposites have shown significantly improved impact strength as well as other properties [3].

Ethylene glycol is a valuable by-product obtained in the process of recycling PUR and PET. Due to the high affinity for water, ethylene glycol has been commercialised for a wide range of uses including desiccant and vaccine manufacture.

Technology

Sourcing

Our waste degradation system is designed to fit with and enhance current waste management practices, especially managing mixed waste. A type of mixed waste called solid recovered fuel (SRF) is produced from recycling plant seeking to recover valuable products from waste. Every year, about 320,000 tonnes SRF containing 30% of plastics is produced per recycling site in the UK, from where SRF is shipped to other countries for incineration. SRF is a cost to these recycling companies as they pay approximately £65 per tonne for shipping. Therefore, we plan to use SRF from the recycling companies as the feedstock, and charge them less than incineration sites. From SRF we will extract the product ethylene glycol and produce a substrate which we can produce the commodity bioplastic, PHB from.We have also designed the first system for PHB recycling, taking responsibility for the end of life solutions to the commodity we are producing. Each step is designed to be carried out in bioreactors.

Mixed waste breakdown

We plan to operate the bioreactors for SRF breakdown at the recycling facilities which produce it originally. The purpose of these facilities is to recover anything of value from waste. A system which could efficiently produce valuable commodities from unrecoverable waste would be welcomed. The important addition to these bioreactors will be membranes capable of filtering ethylene glycol from the remaining material. This are placed downstream of the reactor and allow for the efficient and specific separation of the product.

Bioreactor safety features

We have come up with a few strategies to prevent release of our bacteria into the environment. Firstly, the bioreactor containing bacteria will have a kill switch that kills bacteria if the bioreactor is opened when operating. Secondly, we lyse the cells at the end of reactions to harvest our product. This also ensures living bacteria will not be released unexpectedly.

Efficiency

We estimate 3% conversion from SRF to PHB

80%*60%*75%*8%=2.88%

We measured that wood, paper and fibers are 80% of the SRF. (There will be some variation since the MRF processes different waste every day) We have measured the weight of the two representative piles of separated SRF and calculated the % distribution. (W/P/F: 97.21g, Plastic: 19.48g)

We estimate that about 50-70% of these materials is cellulose. (60% in calculations) This is the component of the equation which is likely to vary the most since it depends on the composition of waste that is processed in the MRF every day. Paper is 100% cellulose. Fibres and textiles can be 100% cellulose (cotton) but can be blended with plastic or rubber. We estimate about 80% of fibres is cellulose. In wood, the [http://www.ipst.gatech.edu/faculty/ragauskas_art/technical_reviews/Chemical%20Overview%20of%20Wood.pdf cellulose is about 42%]. (20% is hemicellulose and some papers show that it can be used for PHA production too.)

We estimate that 75% of cellulose can be converted to glucose by currently available technologies. The toughest cellulosic substrates are crystalline insoluble forms like paper. Some of the latest methods can achieve as high as [http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2849193/ 74.4%] conversion even with these substrates. Therefore, we are confident that it is possible to efficiently convert 75% of cellulose from wood-paper-fibres into glucose. An other [http://onlinelibrary.wiley.com/doi/10.1002/biot.201200033/pdf review] confirms that chemical and ennzymatic cellulose hydrolysis techniques are very advanced and efficient.

We can convert 8% of glucose into PHB with our hybrid operon in E.coli. In our experimental results, we produced 2.48 g/L PHB on 3% glucose LB media, grown for 1 day. Therefore, we calculate that 3% of the glucose is converted with this method.

Our models predict similar conversion from glucose to PHB.

Market analysis

Market for bioplastics

Plastics represent a large percentage of materials used, as they can be applied in products ranging from water bottles and EE (electrical and electronic) equipments to agricultural mulch film and textiles.

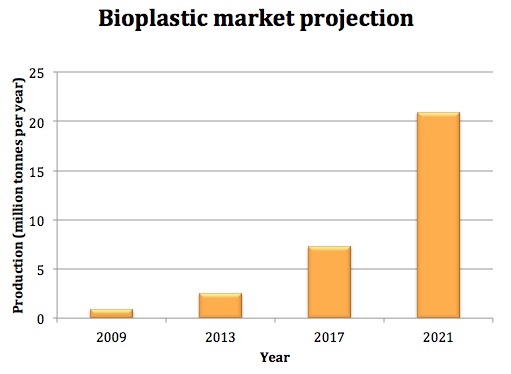

Although bioplastics count only a small percentage of the total plastics currently, driven by the increasing petroleum price, consumer and policy pressure of using greener products, the market for bioplastics is predicted to grow 30% per year [3], and market share is predicted to approach 25%-30% by 2020 [5]. Among all types of bioplastics, biopolyesters such as PHB are predicted as the drive for the market [7]. This significant increase in market share also imply that our bioplastics recycling technology has great importance in the near future, as it contributes to building a circular economy encouraged by the legislations.

Competitive comparison

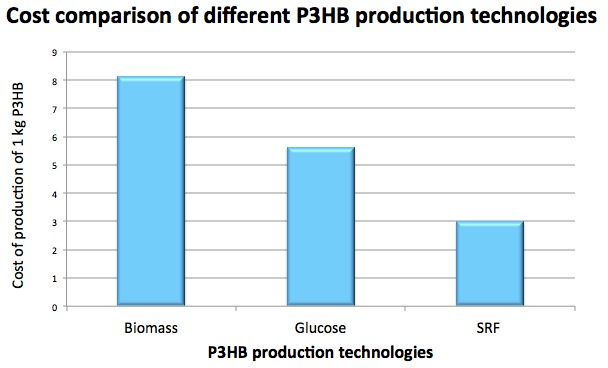

There are existing P3HB producing companies that utilise genetically modified plants or microbes to produce P3HB. However, the technologies they developed cost higher than our technology, as shown in the graph. Plant-based technology cost estimation is based on switchgrass, which shows the highest P3HB production efficiency (3.7% of total dry mass) compared to other plants [6]. Apart from the cost, many other problems are potentially associated with existing technologies. For instance, plant-based technologies require a large growth area, plants have slow growth rate compared to bacteria, and current microbe-based methods demands glucose produced from corn as the feedstock.

References

- Terada, M. & Marchessault, R. H. (1999) Determination of solubility parameters for poly(3-hydroxyalkanoates). International Journal of Biological Macromolecules. . 25 (1-3), 207-215.

- Miguel, O., FernandezBerridi, M. J. & Iruin, J. J. (1997) Survey on transport properties of liquids, vapors, and gases in biodegradable poly(3-hydroxybutyrate) (PHB).Journal of Applied Polymer Science.. . 64 (9), 1849-1859.

- Pilla, S. (2011) Handbook of Bioplastics and Biocomposites Engineering Applications 1st edition. USA, Scrivener Publishing LLC.

- EHuang, J. C., Shetty, A. S. & Wang, M. S. (2003) Biodegradable plastics: A review. Advances in Polymer Technology. 10 (1), 23-30.

- Helmut Kaiser consultancy. (2010) Bioplastics market worldwide 2010/11-2015-2020-2025. [Online] Hong Kong. Available from http://www.hkc22.com/bioplastics.html. [Accessed: June 2013].

- Somleva, M. N., Snell, K. D., Beaulieu, J. J., Peoples, O. P., Garrison, B. R. & Patterson, N. A. (2008) Production of polyhydroxybutyrate in switchgrass, a value-added co-product in an important lignocellulosic biomass crop. Plant Biotechnology Journal.6 (7), 663-678.

- Research and Markets. (2012) Bioplastics - A Global Market Watch, 2011 - 2016. [Online] U.S. Available from http://www.researchandmarkets.com/research/z7dzsv/bioplastics_a

"

"