Team:Imperial College/tour

From 2013.igem.org

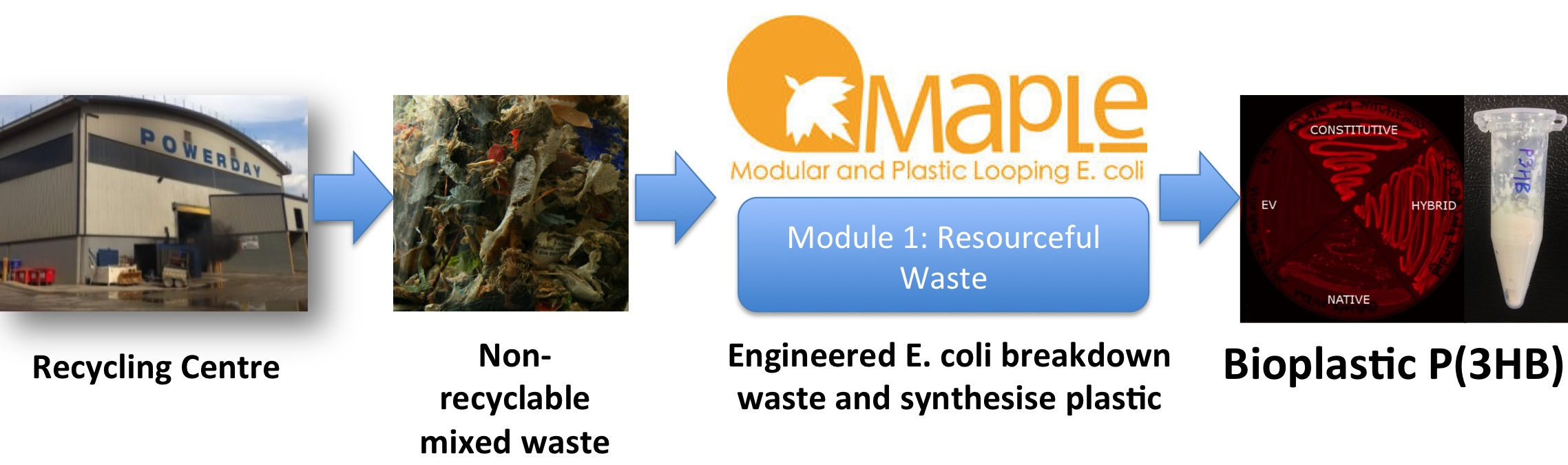

Engineering microbes to make environmentally friendly plastics from non-recyclable waste

We have taken an expensive byproduct of recycling facilities, a type of mixed waste and turned it into something quite amazing. A material that can be used for a diverse range of applications from making your lunchbox to a 3D printed tissue scaffold; this material is the bioplastic poly-3-hydroxybutyric acid(P3HB). Our system is designed to maximise the recovery of resources from the waste and so we have also investigated how we can use the oil based plastics within the waste to produce the comommodity chemical ethylene glycol. We are passionate about using synthetic biology to help us move towards a more sustainable economy. We have also considered what happens to the material we produce after it is used. This led us to develop the first recycling system for P3HB and a biological one at that. The other well known bioplastic, poly lactic acid (PLA) is also expanding in use and so we developed a system to turn it back into its constituent monomers so that it can be chemically resynthesised or even created in vivo.

Click here to find out how we made P3HB and broke down oil derived plastics and here to see how we recycled it P3HB and PLA.

Global Challenge: The world produces mountains of waste!

The Waste Issue

Waste is a major byproduct of our free market society. Every year, over 3 billion tonnes (Gt) of waste are produced within the European Union [http://ec.europa.eu/environment/waste/]. This includes municipal solid waste (MSW), industrial and hazardous waste. We have estimated that between 2005 to 2050, enough waste will be produced to create a mountain half the size of Everest. Plastic waste alone, at ten percent of the total will produce a mountain the size of Mont Blanc, the largest mountain in the EU. Even more significantly, this represents only a fraction of the world's population, approximately 500 million live within the EU. When we look at the American figures, we see that solely industrial waste comes to around 7.6 Gt [http://www.epa.gov/wastes/nonhaz/industrial/guide/], and this figure was from the 1980s, since then it has no doubt increased per capita as it has in Europe. Due to the necessities of living, we are always going to produce waste. Couple this with a human population of over 7 billion and increasing consumerism around the world and this waste really starts to add up. The mismanagement of waste is not only leading to severe environmental problems but social ones also. The shipping of waste around the world is a disturbing problem but one that makes economic sense. This needs to change.

Landfill

Every year, tonnes of waste are disposed in landfill sites and the materials are lost forever. Plastics, designed to be resistant to biodegradation, can potentially remain in the land forever. Subsequently, the “lifespan” of landfill sites are extremely limited.

Apart from these, methane and carbon dioxide produced in landfill sites cannot be captured to generate energy, but released in the atmosphere, enhancing the greenhouse effect.

Meanwhile, harmful substances including acid gases released from landfill sites severely affect human health [1]. For example, babies of women living within 7km away rom hazardous landfill sites have a significant excess of non-chromosomal congenital anomalies.

Incineration

Incineration is the conversion of materials to carbon dioxide and water. During the combustion process, heat and electricity can be generated with an efficiency of 27% [2]. Thus incineration is a one-time-only affair; the resources which went into the production of these materials are lost to the atmosphere... Meanwhile, ash generated in incinerators, counting for more than 28% of the total waste fed in, has no market as its toxic component poses risks to human health [3].

Incinerator emissions do not just damage the environment [4], people from all age groups who live 3 km to 7.5 km away from incinerators have shown substantial excess cancers [5] [6]. Statistically significant excess of cancer births have also been observed near industrial incinerators.

Gasification

Gasification is the conversion of materials with carbon and hydrogen in their chemical structure into syngas i.e. hydrogen gas and carbon monoxide, which are combusted to produce electricity with an efficiency of 37% [2]. Gasification requires intensive energy input to achieve 1200 to 2000 working temperature and 6900 kPa working pressure [2] [7]. Gasification is still facing many challenges. For instance ash and dust can pollute the syngas, and most gasifiers requires external heat supply [8].

For materials like plastics, the gasification products are sometimes used to re-form the monomers for plastics, which costs more energy than breaking down to monomers [2], and the energy used for production of the material is wasted.

Recycle

If paper, cardboard plastics, metals and wood are kept chemically pure and physically separated then they can often be recycled and reused. However a large percentage of our waste is mixed together or contaminated with food waste and other contaminants. The consequence of this is that mixed waste cannot be recycled with current technologies.

Current recycling facilities are not very well developed, as manpower is essential in separating different types of materials in waste. This means recycling is not efficient, and employees in recycling sites often have to work in hyperthermal and dusty environment, risking their health.

Our System: Modular and Plastic Looping E. coli (M.A.P.L.E.)

Module 1: Resourceful Waste

Non-recyclable waste is sourced from a recycling centre, placed in a bioreactor with our M.A.P.L.E system which degrades the waste and synthesises the bioplastic P(3HB).

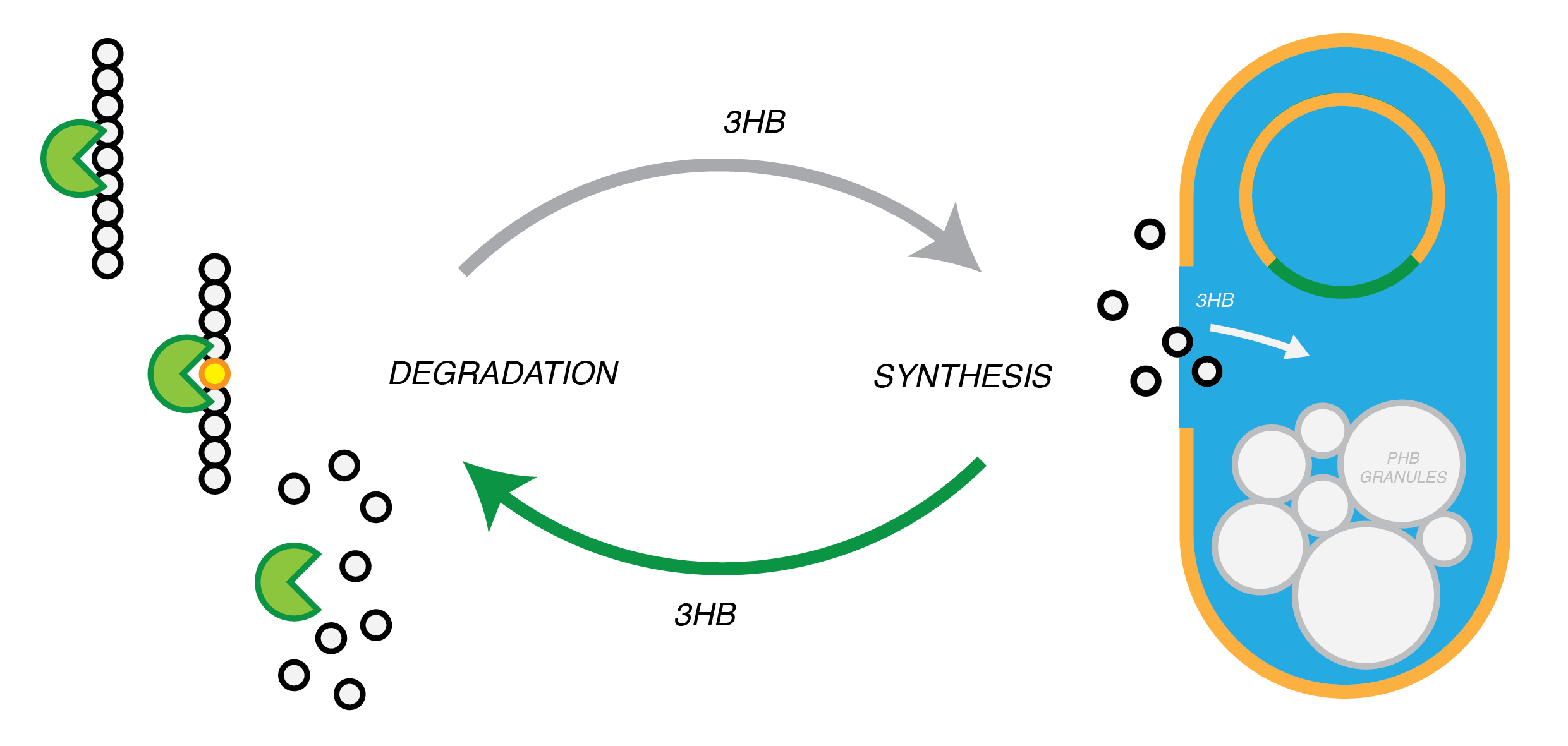

Module 2: Plastic Fantastic

Plastic Fantastic is a complete P(3HB) bioplastic recycling platform, where P(3HB) is degraded into monomeric form and then re-polymerised back into de novo P(3HB) for future applications.

"

"