Team:Imperial College/MSDS

From 2013.igem.org

Safety

Safety forms were approved on October 2nd, 2013 by the iGEM Safety Committee.

1. Do the biological materials used in the lab work pose any risks to the safety and health of team members or others working in the lab?

In the project, we used Escherichia. coli K-12 strains MG1655, NEB 10 beta, NEB 5 alpha and TOP10 (similar to E. coli K-12 DH 10 beta. E. coli K-12 strains fall under Risk Group 1, matching our [http://www.who.int/csr/resources/publications/biosafety/Biosafety7.pdf BL1] (Biosafety Level 1) laboratory. Before using the strain, the team has researched risks relating to usage of this strain.

E. coli K-12 strains have commensal lifestyles, i.e. they consumes carbon compounds from food in host gut without harming the host. Risk assessments of E. coli K-12 strains indicate that they are poor colonisers of human and animal gut, due to lack of three cell wall components, glycocalyx, liposaccharide core and capsular antigens, that are responsible for recognition and adhesion of gut cells [1]. Experiments have shown that E. coli K-12 strains cannot colonise human intestinal tracts, where wild type E. coli resides, unless normal gut flora are substantially reduced [2] [3]. Meanwhile, E. coli K-12 strains are unable to produce significant amount of toxin to cause diseases [4].

Most of the enzymes produced by the engineered E. coli K-12 strains are unable to interact with human proteins. Although proteinase K has can potentially degrade human protein beta amyloid plaques [5], this protein is only abundant in patients with Alzheimer’s disease, and neither the bacteria or proteinase K is likely to pass the blood-brain-barrier.

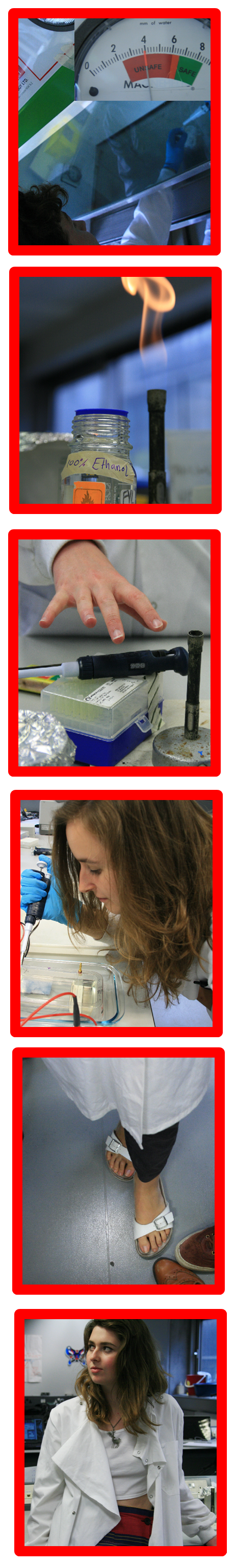

Imperial College London Safety Department is a dedicated department responsible for providing safety guidelines. In order to prevent contamination and infection, Imperial College has established [http://www3.imperial.ac.uk/safety/policies health and safety rules]. For example no eating or drinking in labs, wearing gloves when handling the lab apparatus, wearing lab coats at all times, disposal of contaminated and non-contaminated equipment into appropriate bins, and keeping the lab area organised and clean.

We have gone through safety training regarding general safety issues, first aid and emergency arrangements, incident reporting, experimental procedures and waste procedures before starting the wet lab work. We have also separated areas and entrances for wet and dry lab work, and the benches are cleaned before and after experiments. In addition, we always keep transformed bacteria in appropriate fridge or freezer, and dispose bacterial contaminated material into the autoclave bag.

2. Do the biological materials used in the lab work pose any risks to the safety and health of the general public, if released by design or by accident?

As described in Question 1, E. coli K-12 strains used by the team should raise no concerns regarding human health and safety. The bioengineered E. coli cells, like the non-engineered ones, also lack the key virulence structures that enable them to infect human or other animals. Therefore, human or animal infection by our bacteria released by accident is highly unexpected. The risk to the general public is that the engineered bacteria might release ethylene glycol to the environment after breaking down polyurethane, which might be toxic to human. However, the activity of the bacteria and enzyme are highly inhibited, as they require certain conditions to work.

The engineered bacteria are not designed to be exposed to the general public. We intend to utilise bioreactors to concentrate these bacteria in order to achieve high efficiency. It is possible that worker near the fermentor can be exposed to these synthetic “machines”, but it is difficult to estimate worker exposure, as related information is not available [6]. To eliminate safety risks to workers, we will use an airtight compartment with kill switches that kill escaped bacteria.

In addition, we always try to prevent release of our bacteria outside the lab. In the labs, all contaminated waste is autoclaved before disposed through controlled routes. The used pipette tips are soaked in 10% RBS 35 detergent for at least one hour before disposal into the contaminated waste bags. In addition, the windows are shut at all times, preventing release of the bacteria and toxic reagents to the outside. Outside the labs, we remove gloves and lab coats. We also wash our hands after finishing experiments and before exiting the lab. Moreover, when collaborators visited the labs, they were asked to wear lab coats and gloves.

3. Do the biological materials used in the lab work pose any risks to the environment, if released by design or by accident?

The niches of E. coli K-12 strains are within human or animal bodies. Non-engineered E. coli has very limited survival in natural environment [6]. Nevertheless, our engineered E. coli has the ability to break down a wide range of plastics, and can potentially use them as food source, providing the right conditions including humidity and temperature. This might cause damage to many objects used in our daily life and industry. Moreover, ethylene glycol, as a product of polyurethane (PUR), might be released in the environment and cause risks to human and animal health.

As described in Question 2, we plan to contain the engineered bacteria within a bioreactor. We have carefully thought about the design of the bioreactor to prevent bacteria from escaping to the environment. For example, add basic buffer to limit cell replication, and set up kill switches that kill all the bacteria if the bioreactor is opened when operating. After digesting and synthesis of bioplastics, the engineered bacteria in the bioreactor will be killed to harvest bioplastics produced within the cells. For implementation within recycling facilities, where a large amount of bacteria will be used, we can design an extra compartment for the bioreactor to further prevent releasing bacteria into the environment.

4. Do the biological materials used in the lab work pose any risks to security through malicious misuse by individuals, groups, or countries?

The enzymes were taken from natural bacteria such as Ralstonia eutropha. These bacteria are already responsible for plastic degradation. Despite this, global plastic waste is still a huge issue throughout the world and will remain so for many hundreds of years.

A major concern would be the use of the engineered bacteria as a bioweapon to rapidly degrade the infrastructure of a society if it was coated by an aerosol attack. This stems from many of our modern products having plastic built into them, this is from phone casings to table finishes to carpets. However, for optimum growth a very moist environment would be a necessity, these conditions are not usually found within a human environment where it is generally very dry. This said, at the equator and South East Asia, to name a few, the environment is naturally highly humid.

By individual countries, a bioweapons attack would potentially have collateral side effects on their own states and would be inefficient. Also most countries follow strict legislations regarding using GMO (genetically modified organisms) both inside and outside laboratories. For example, the UK has a list of [http://www.biosafety-europe.eu/d20public_300309.pdf. legislations and regulations] regarding biosafety and biosecurity. For a terrorist group however, it would be very hard to detect their means, which would cause chaos, under the right conditions.

5. If your project moved from a small-scale lab study to become widely used as a commercial/industrial product, what new risks might arise?

E. coli K-12 strains are poor colonisers and infectors of human and animal bodies, and they are not likely to habit natural environment such as soil and river. Also, only when the environmental conditions are appropriate, our engineered bacteria will degrade plastics, which is causing global waste problems. Hence, the risks are kept at a very low level, even if our project is developed in large-scale.

6. Does your project include any design features to address safety risks?

We have come up with a few strategies to prevent release of our bacteria into the environment. Firstly, the bioreactor containing bacteria will have a kill switch that kills bacteria if the bioreactor is opened when operating. Secondly, we lyse the cells at the end of reactions to harvest our product. This also ensures living bacteria will not be released unexpectedly. The team is also considering to establish symbiosis between bacteria with different plastic-degrading enzymes, so that the bacteria only live when two or more strains are present.

7. What safety training have you received?

We have received safety training regarding general safety issues, first aid and emergency arrangements, incident reporting, experimental procedures and waste procedures.

For more specific safety information please see our module pages

M1: Resource-full Waste

Bioplastic Recycling Module

References

- Anderson, E. S. (1975) Viability of, and transfer of a plasmid from, E. coli K12 in the human intestine. Nature. 255(), 502-504.

- Curtiss, R. (1978) Biological Containment and Cloning Vector Transmissibility. Journal of Infectious Diseases. 137 (5), 668-675.

- Du, D., Murray, A. N., Cohen, E., Kim, H. E., Simkovsky, R., Dillin, A. & Kelly, J. W. (2011) A kinetic aggregation assay allowing selective and sensitive amyloid-β quantification in cells and tissues. [Online] 50 (10), 1607-1617. Available from: doi:10.1021/bi1013744 [Accessed 26th January 2011].

- Edberg, S. (1991) Human health assessment of Escherichia coli K-12. Unpublished, U.S. Environmental Protection Agency, Washington, D.C.

- LaVeck, G. (1991) Exposure assessments of microorganisms considered for 5(h)(4) exemptions under the proposed biotech rule. Unpublished, U.S. Environmental Protection Agency, Washington, D.C.

- Reilly, B. (1991) Analysis of environmental releases and occupational exposure in support of proposed TSCA 5(h)(4) exemption. Unpublished, U.S. Environmental Protection Agency, Washington, D.C.

"

"