Team:Imperial College/mainresults

From 2013.igem.org

Main Results

Resource-full Waste

Plastic Fantastic

We made P3HB bioplastic ▼

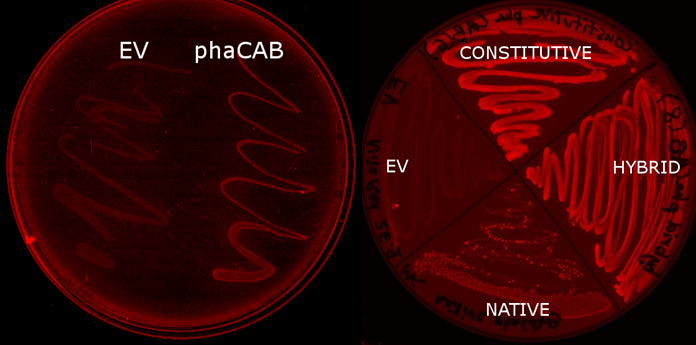

We used E. coli that expresses PhaCAB enzymes to make P3HB bioplastic. This is tested on nile red plates which stains P3HB.

Modelling ▼

Using model simulation results, we predict that the concentration of PhaCAB enzymes

We optimised bioplastic production ▼

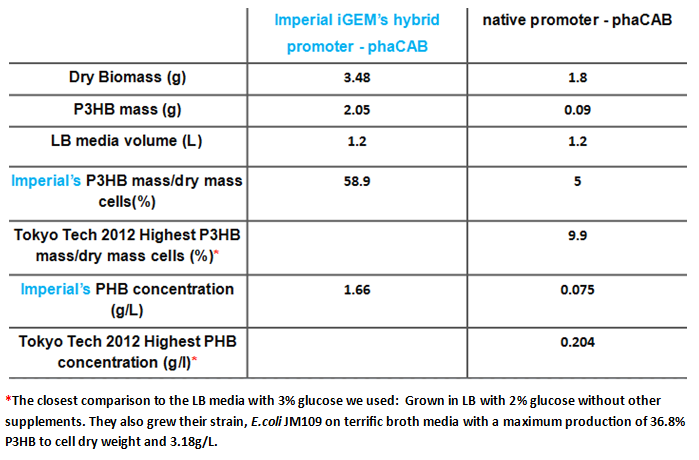

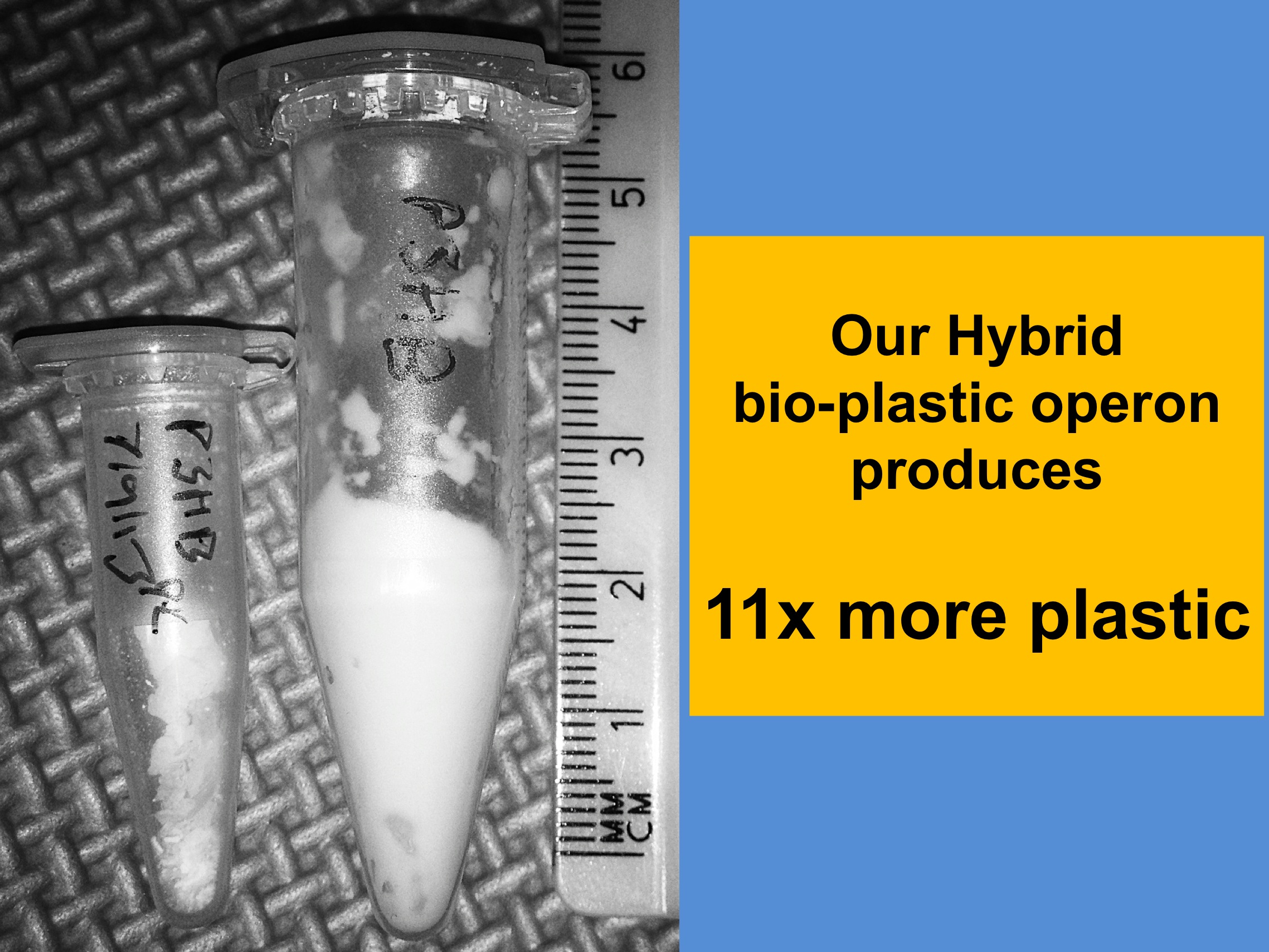

Since our model predicts that the concentration of PhaB enzymes is the rate limiting step in P3HB production, we designed a [http://parts.igem.org/Part:BBa_K1149051 hybrid promoter] consists of the J23104 constitutive promoter and the native promoter to optimise gene expression. Our results show that we have successfully produced 11-fold more P3HB bioplastic compared with the native promoter.

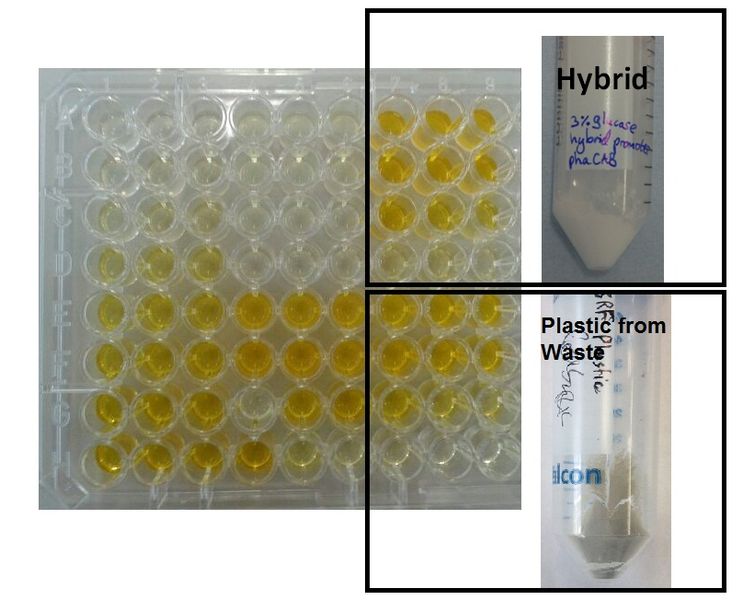

We made bioplastic from mixed waste ▼

One of the objectives of Module 1 is to produce P3HB bioplastic from waste. By comparing degradation product 3HB of P3HB bought from Sigma, produced from glucose and produced from the waste, we found there is no significant differences in 3HB concentration between these samples.

E. coli feeds on 3HB ▼

We degraded P3HB ▼

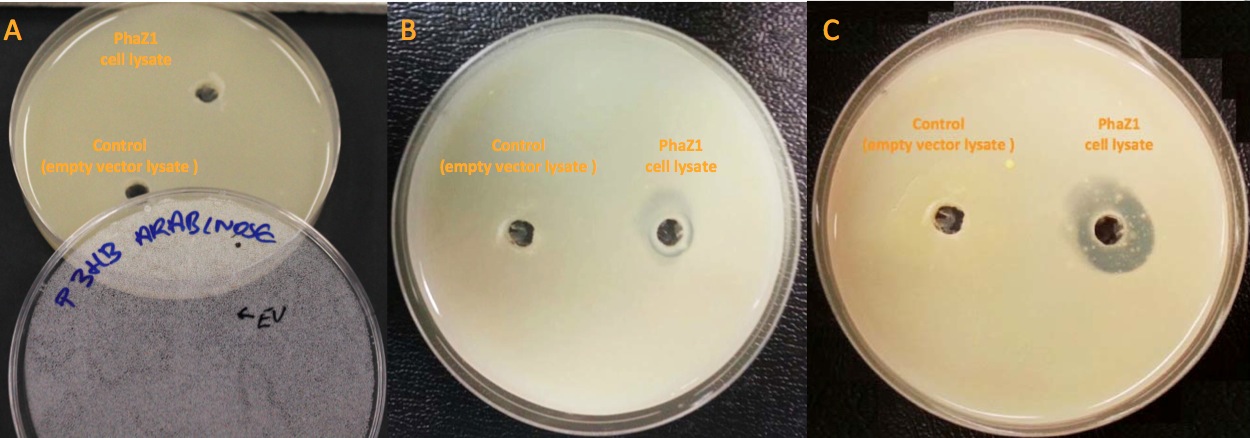

Our clearing zone assay indicates that P3HB depolymerase PhaZ1 started to fairly quickly degrade P3HB from the first day. After 3 days, there is evidently a clear zone around the well containing PhaZ1. We are the first iGEM team to degrade bioplastics!

We degraded P3HB we made from waste ▼

Using 3HB colourimetric assay kit, we have shown that we have degraded the P3HB made from waste into 3HB monomers. In addition, there is no significant difference in 3HB concentration between different P3HB sources. This result proves that we now have a closed loop for P3HB bioplastic recycling!

We degraded PLA ▼

"

"