Team:Edinburgh/Modeling/Engineering model

From 2013.igem.org

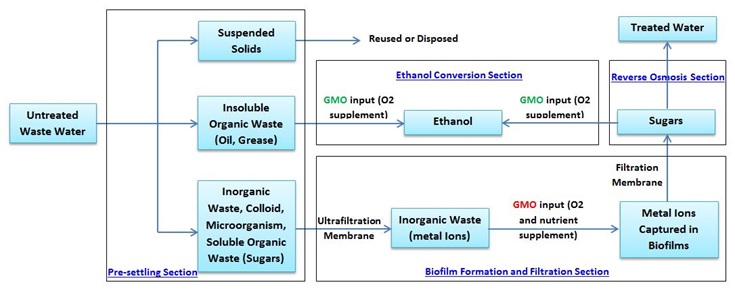

Notes for design flow chart

GMO (green), genetically modified bacillus subtilis (Optimised Bacillus), able to ferment organic components to produce biofuels GMO (red), genetically modified bacillus subtilis (Optimised Bacillus), able to capture ions using chelators and metal binding proteins

Contents |

Design

Based on the functions of our GMO model, Optimised Bacillus (referred as OB), we conceptually design an industrial wastewater treatment system, as demonstrated by the figure above. The system is divided into four sections and they are pre-settling, biofilm formation and filtration, reverse osmosis sections and ethanol conversion. Ideally, all these four sections will be able to accomplish tasks including capturing toxic metal ion, producing biomass from organic waste and purifying the water to a safe level for, e.g. irrigation or drinking.

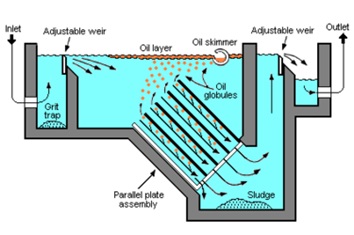

Pre-settling

In the pre-settling section, the untreated wastewater will be fed into a parallel plate separator. As we can see from the schematic of the separator, insoluble organic waste such as oil and grease will be collected at the surface of the water by a skimming device, which is connected to the ethanol conversion section for biofilm production. Most, not necessarily all, insoluble and suspended solids will either go down to the bottom of the tank or up to the surface of the water, and will be collected by a scraper when they accumulate to some extent. There are only inorganic waste (metal ion), colloid, microorganism, and soluble organic waste like sugars left in the wastewater.

Biofilm Formation and Filtration

In the first stage of this section, the pre-settled water will be forced through an ultrafiltration membrane by pressure supplied by the system. The membrane filter acts as a molecular sieve (pore size 0.01~0.1µm) to stop colloid and microorganism (which may consume nutrient and oxygen supplement for the OB) from going into next stage. Suspended solids that are not removed in the pre-settling section will be completely eliminated from the water. The heavy metal ion in the filtrate will be detected by the genetically modified organism, Optimised Bacillus. With supplement of oxygen and nutrients, the OBs will then produce metal binding protein to capture the metal ion, and also produce chelators, which form biofilm to bind the OBs as well as the binding protein. The biofilm has a rapidly increasing molecular weight and soon becomes big enough (to visible level) to be retained by a filtration membrane. The method of metal ion capture is similar to an existing study. According to the paper published by Katarina Trivunac et al. in 2006, the removal of Cd2+ and Zn2+ was more than 95% and 99% by using water-soluble macroligands to bind metal ions (increase molecular weight) and collect the loaded agent with an ultrafiltration membrane.

Reverse Osmosis

The reverse osmosis (see previous chapter for how the RO works) section is used to recover the sugar (e.g. glucose) from the output from biofilm formation and filtration section. By applying a pressure (higher than the one required in ultrafiltration) on the sugar solution, a highly concentrated sugar solution can be produced. At the same time, the wastewater is fully treated by achieving a high purity. Since the reverse osmosis process requires a high pressure (high energy consumption) and gives a low water flow rate (low productivity of clear water), the reverse osmosis section will only be activated when the concentration of sugar in feeding water is high enough after the treatment in the biofilm formation and filtration section. The actual sugar level to trigger the purification process should be tested after a well development of the system and also the Optimized Bacillus.

Ethanol Conversion

Along with the concentrated sugar solution (if there is any), the insoluble organic waste extracted from the pre-settling section will be fed into the ethanol conversion section. With oxygen supplement, fermentation of sugars and organic waste will be triggered, efficiently producing ethanol. Procedures to separate ethanol from the cells and organic waste, in order to obtain high purity of ethanol at the output of the system have not yet been decided. Another ultrafiltration membrane is preferred. The mixed liquid after the fermentation (ideally only OBs and ethanol) will be delivered to an ultrafiltration container, where OBs will be filtered and ethanol of high purity will be produced. Since it will be a non-continuous process, the section will require more deliberate design to improve the performance and biomass production.

|

| | | |

|

| This iGEM team has been funded by the MSD Scottish Life Sciences Fund. The opinions expressed by this iGEM team are those of the team members and do not necessarily represent those of MSD | |||||

"

"