Team:Edinburgh/Modeling/Engineering model

From 2013.igem.org

Contents |

Engineering Model

Notes for design flow chart

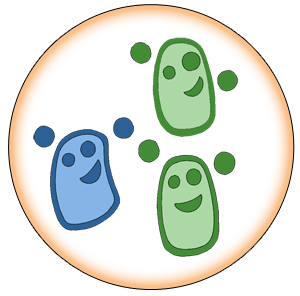

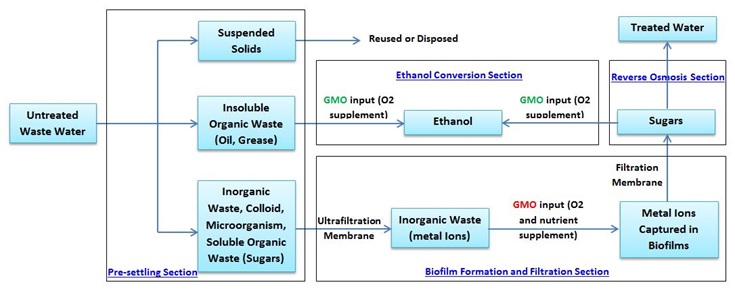

GMO (green), genetically modified bacillus subtilis (Optimised Bacillus), able to ferment organic components to produce biofuels GMO (red), genetically modified bacillus subtilis (Optimised Bacillus), able to capture ions using chelators and metal binding proteins.

Design

Based on the functions of our GMO model, Optimised Bacillus (referred as OB), we designed an industrial wastewater treatment system, as demonstrated by the figure above. The system is divided into four sections: pre-settling; biofilm formation and filtration; reverse osmosis sections and ethanol conversion. The four sections will be able to capture toxic metal ions, produce biomass from organic waste and purify the water to a safe level for irrigation or drinking.

Pre-settling

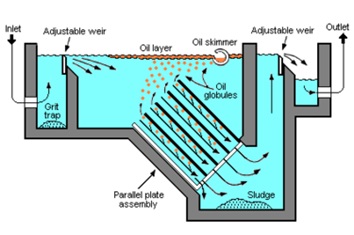

In the pre-settling section, the untreated waste water will be fed into a parallel plate separator. As we can see from the schematic of the separator, insoluble organic waste such as oil and grease will be collected at the surface of the water by a skimming device, which is connected to the ethanol conversion section for biofilm production. Most, not necessarily all, insoluble and suspended solids will either go down to the bottom of the tank or up to the surface of the water, and will be collected by a scraper when they accumulate. There should be only inorganic waste (metal ions), colloids, microorganisms, and soluble organic waste like sugars left in the waste water.

Biofilm Formation and Filtration

In the first stage of this section, the pre-settled water will be forced through an ultrafiltration membrane by pressure supplied by the system. The membrane filter acts as a molecular sieve (pore size 0.01~0.1µm) to stop colloids and microorganisms (which may consume nutrient and oxygen supplements for the OB) from going into the next stage. Suspended solids that are not removed in the pre-settling section will be completely eliminated from the water. The heavy metal ions in the filtrate will be detected by the genetically modified organism, Optimised Bacillus. With supplementary oxygen and nutrients, the OBs will then produce a metal binding protein to capture the metal ion. A biofilm will aggregate the OBs along with the binding protein. The biofilm has a rapidly increasing molecular weight and will soon become big enough (to a visible level) to be retained by a filtration membrane. The method of metal ion capture is similar to an existing study. According to the paper published by Katarina Trivunac et al. in 2006, the removal of Cd2+ and Zn2+ was more than 95% and 99% by using water-soluble macroligands to bind metal ions (increase molecular weight) and collect the loaded agent with an ultrafiltration membrane.

Reverse Osmosis

The reverse osmosis (see previous chapter for how the RO works) section is used to recover the sugar (e.g. glucose) from the output from biofilm formation and filtration section. By applying a pressure (higher than the one required in ultrafiltration) to the sugar solution, a highly concentrated sugar solution can be produced. At the same time, the waste water is fully treated, achieving a high purity. Since the reverse osmosis process requires a high pressure (high energy consumption) and gives a low water flow rate (low productivity of clear water), the reverse osmosis section will only be activated when the concentration of sugar in the feeding water is high enough, following treatment in the biofilm formation and filtration section. The actual sugar level required to trigger the purification process should be tested after development of the system and the Optimized Bacillus.

Ethanol Conversion

Along with the concentrated sugar solution (if there is any), the insoluble organic waste extracted from the pre-settling section will be fed into the ethanol conversion section. With oxygen supplementation, fermentation of sugars and organic waste will be enabled, efficiently producing ethanol. Procedures to separate ethanol from the cells and organic waste, in order to obtain high purity of ethanol at the output of the system, have not yet been decided. Another ultrafiltration membrane is preferred. The mixed liquid after the fermentation (ideally only OBs and ethanol) will be delivered to an ultrafiltration container, where OBs will be filtered and ethanol of high purity will be produced. Since it will be a non-continuous process, the section will require more deliberate design to improve the performance and biomass production.

Evaluation

Viability of the model

One may question the viability or reliability of the system model described above, which involves microorganism and filter membrane etc., and also requires oxygen and pressure supply. However, reliable systems with all these elements implemented have been widely used for sewage and industrial wastewater treatment.

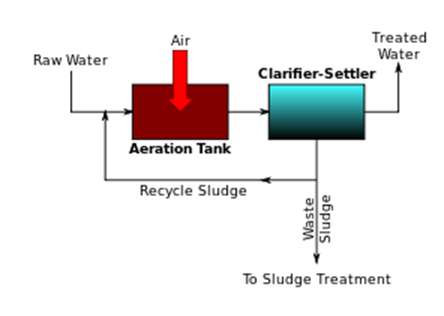

Activated sludge (aerobic treatment system) is a process for reducing organic waste in sewage and industrial wastewater by supplying sufficient amount of oxygen or air to an aerobic organism. The organism, which in healthy sludge is a brown floc, is largely composed of saprotrophic bacteria but also has an important protozoan flora (including amoebae and Spirotrichs etc.). The organisms consume organic wastes and oxygen to produce a floc, which will settle and be collected afterwards in a settler (see schematic above).

Schematic of Membrane Bioreactor

A membrane bioreactor can be introduced to reduce the space required for activated sludge devices, as demonstrated in the schematic above. All biological reactions are contained between two ultrafiltration membranes, which effectively separate organisms and floc from treated water and remove a settler from the system. The biofilm formation and filtration section will have a similar design layout as the membrane bioreactor. By introducing input pipes to deliver nutrient to the reaction container, the system should be capable of maintaining the biofilm formation for removal of metal ions. A reliable metal ion detection and elimination system proposed in the previous chapter is therefore considered achievable. Similarly, a reliable system model can also be developed for ethanol conversion section, with modifications on the membrane bioreactor.

Market prospect of metal ion capturing GMO

Among existing water purification technologies that is capable of removing metal ion from wastewater, electodeionization is considered to be a more cost-effective (lower cost and higher purity) method than distillation. Reverse osmosis, on the other hand, is usually included as a pre-purification procedure in commercial treatment system. (See URL link: http://www.labcompare.com/10-Featured-Articles/18907-RO-EDI-The-Preferred-Water-Purification-Technology-for-Food-and-Beverage-Laboratories/).

When comes to the comparison between electodeionization and metal ion capturing GMO, there is not experimental data available to compare the performance of the two methods. However, the Optimized Bacillus has an obvious advantage over the electodeionization basing on current level of knowledge. According to the design pathway of genetic modification, the OB is capable of detecting specific metals ion and then capturing them using chelator and metal binding protein. The OB is hence able remove one specific type of metal ion from the wastewater under ideal circumstances. This function will be very helpful when there is a small amount of metal ions (e.g. Cd2+ and Pb2+) mixed in one type of metal ion (e.g. large amount of Zn2+). The OBs can remove Cd2+ and Pb2+, producing a highly pure Zn2+ solution, which can then be recycled. Metal ions cannot be separated from each other when using electodeionization.

Therefore, it is believed that purification technology basing on Optimized Bacillus for metal capture will gain market share in wastewater treatment systems which aims to recycle high purity of some specific type of metal ion, or small treatment module developed to be implemented in large treatment system which enables the system to remove some type of metal ion (for example, highly toxic element As) from the concentrated metal ion solution.

Reference and bibliography

1.European Commission. 2002. Heavy metal in waste. 2.Duruibe, J. O., Ogwuegbu, M. O. C. and Egwurugwu, J. N. 2007. Heavy metal pollution and human biotoxic effects. International Journal of Physical Sciences. 3.World Health Organization. 2006. Guideline for drinking-water quality. 4.RSD®. Purification technologies. URL: http://www.ro-di.com/en/chjs.asp 5.HERCO. treatment. URL: http://herco-wt.de/index.php/en/methods.html 6Crescenzi G., Norris M. RO/EDI: The Preferred Water Purification Technology for Food and Beverage Laboratories. URL: 7.http://www.labcompare.com/10-Featured-Articles/18907-RO-EDI-The-Preferred-Water-Purification-Technology-for-Food-and-Beverage-Laboratories/ 8.Wikipedia

|

| | | |

|

| This iGEM team has been funded by the MSD Scottish Life Sciences Fund. The opinions expressed by this iGEM team are those of the team members and do not necessarily represent those of MSD | |||||

"

"