Team:Imperial College/tour

From 2013.igem.org

Iain Bower (Talk | contribs) |

Iain Bower (Talk | contribs) |

||

| Line 7: | Line 7: | ||

We have taken an expensive byproduct of recycling facilities, a type of mixed waste and turned it into something quite amazing. A material that can be used for a diverse range of applications from making your lunchbox to a 3D printed tissue scaffold; this material is the bioplastic poly-3-hydroxybutyric acid(P3HB). Our system is designed to maximise the recovery of resources from the waste and so we have also investigated how we can use the oil based plastics within the waste to produce the comommodity chemical ethylene glycol. We are passionate about using synthetic biology to help us move towards a more sustainable economy. We have also considered what happens to the material we produce after it is used. This led us to develop the first recycling system for P3HB and a biological one at that. The other well known bioplastic, poly lactic acid (PLA) is also expanding in use and so we developed a system to turn it back into its constituent monomers so that it can be chemically resynthesised or even created in vivo.</p> | We have taken an expensive byproduct of recycling facilities, a type of mixed waste and turned it into something quite amazing. A material that can be used for a diverse range of applications from making your lunchbox to a 3D printed tissue scaffold; this material is the bioplastic poly-3-hydroxybutyric acid(P3HB). Our system is designed to maximise the recovery of resources from the waste and so we have also investigated how we can use the oil based plastics within the waste to produce the comommodity chemical ethylene glycol. We are passionate about using synthetic biology to help us move towards a more sustainable economy. We have also considered what happens to the material we produce after it is used. This led us to develop the first recycling system for P3HB and a biological one at that. The other well known bioplastic, poly lactic acid (PLA) is also expanding in use and so we developed a system to turn it back into its constituent monomers so that it can be chemically resynthesised or even created in vivo.</p> | ||

| - | <p> Click [[Team:Imperial_College/Waste_Degradation:_SRF|here]] to find out how we made P3HB and broke down oil derived plastics and [[Team:Imperial_College/ | + | <p> Click [[Team:Imperial_College/Waste_Degradation:_SRF|here]] to find out how we made P3HB and broke down oil derived plastics and [[Team:Imperial_College/BioPlastic_Recycling:_PHB|here]] to see how we recycled it P3HB and PLA.</p> |

Revision as of 00:16, 3 October 2013

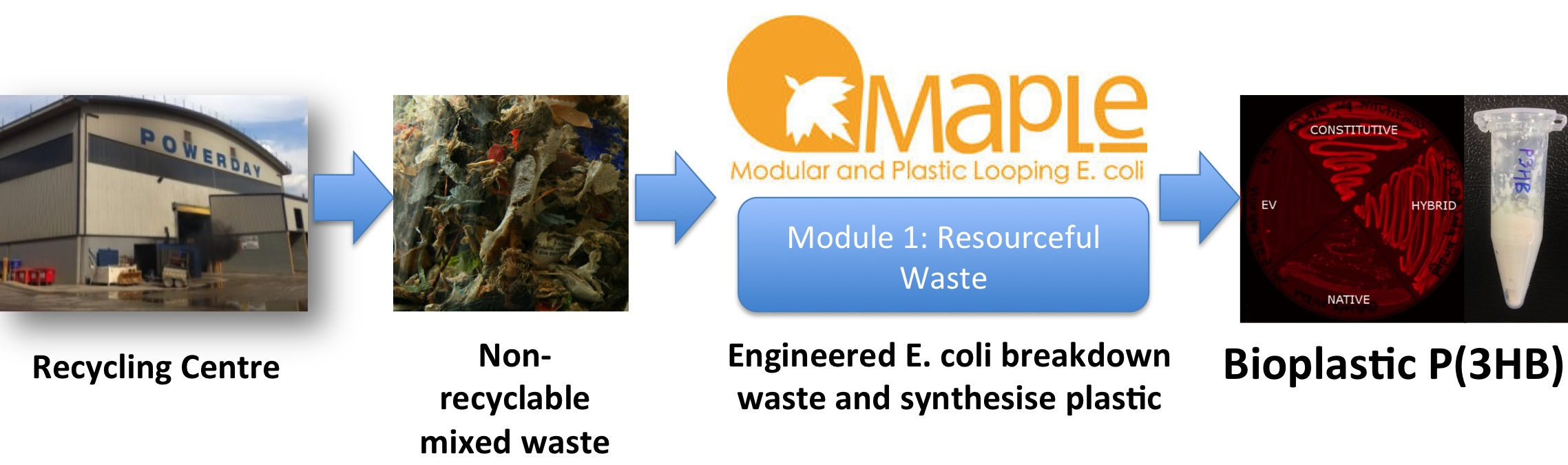

Engineering microbes to make environmentally friendly plastics from non-recyclable waste

We have taken an expensive byproduct of recycling facilities, a type of mixed waste and turned it into something quite amazing. A material that can be used for a diverse range of applications from making your lunchbox to a 3D printed tissue scaffold; this material is the bioplastic poly-3-hydroxybutyric acid(P3HB). Our system is designed to maximise the recovery of resources from the waste and so we have also investigated how we can use the oil based plastics within the waste to produce the comommodity chemical ethylene glycol. We are passionate about using synthetic biology to help us move towards a more sustainable economy. We have also considered what happens to the material we produce after it is used. This led us to develop the first recycling system for P3HB and a biological one at that. The other well known bioplastic, poly lactic acid (PLA) is also expanding in use and so we developed a system to turn it back into its constituent monomers so that it can be chemically resynthesised or even created in vivo.

Click here to find out how we made P3HB and broke down oil derived plastics and here to see how we recycled it P3HB and PLA.

Our System: Modular and Plastic Looping E. coli (M.A.P.L.E.)

Module 1: Resourceful Waste

Non-recyclable waste is sourced from a recycling centre, placed in a bioreactor with our M.A.P.L.E system which degrades the waste and synthesises the bioplastic P(3HB).

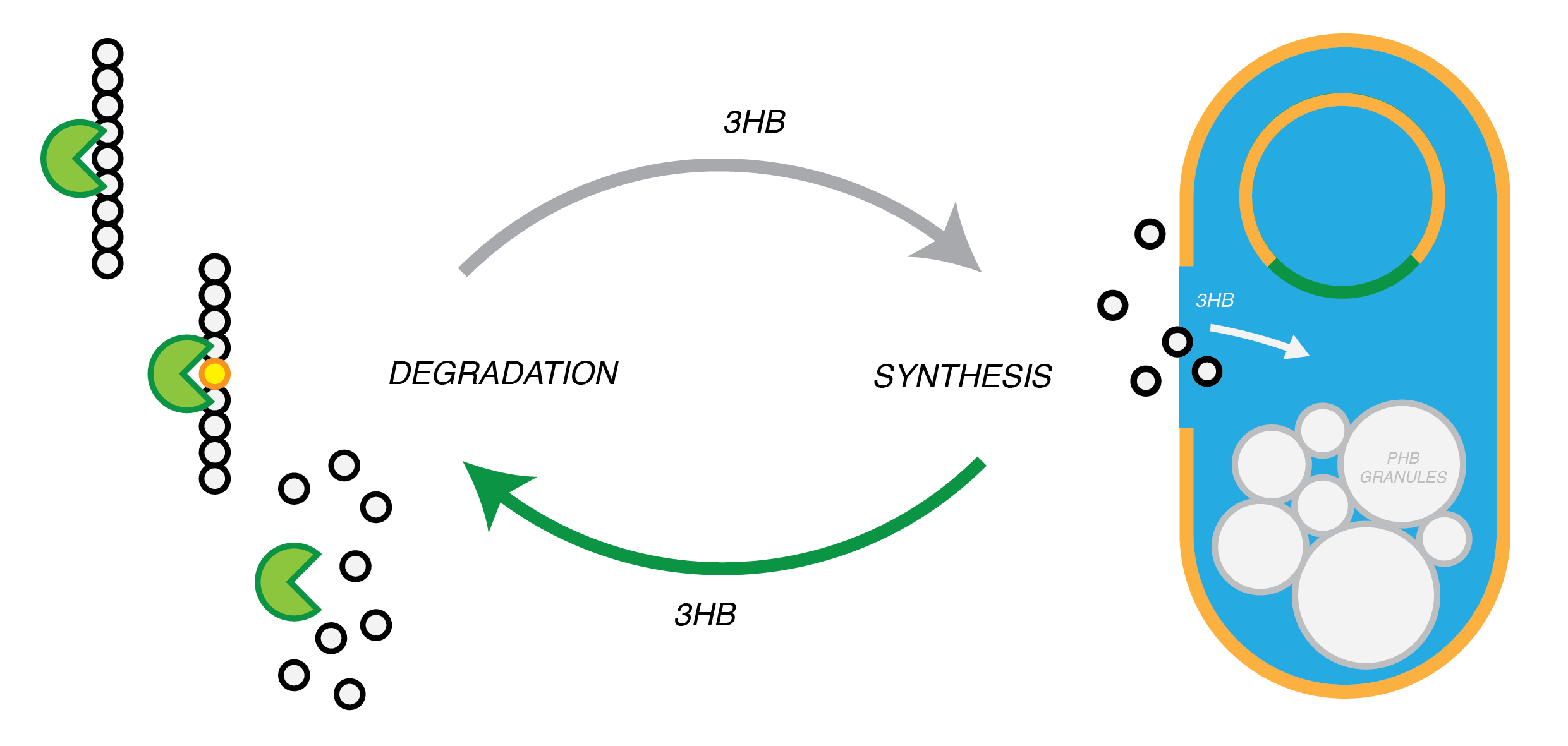

Module 2: Plastic Fantastic

Plastic Fantastic is a complete P(3HB) bioplastic recycling platform, where P(3HB) is degraded into monomeric form and then re-polymerised back into de novo P(3HB) for future applications.

"

"