Team:TU-Munich/Modeling/Filter

From 2013.igem.org

| Line 18: | Line 18: | ||

<option selected="selected">Custom</option> | <option selected="selected">Custom</option> | ||

</select></p> | </select></p> | ||

| - | <p id="activity">Enter enzyme activity | + | <p id="activity">Enter enzyme activity (k<sub>cat</sub>/k<sub>M</sub>) in M<sup>-1</sup>s<sup>-1</sup>: <input type="text" /></p> |

| - | <p id="mass">Enter molecular mass: <input type="text" /> | + | <p id="mass">Enter molecular mass in Da: <input type="text" /></p> |

| - | <p id="flow">Flowrate: <input type="text" /> | + | <p id="flow">Flowrate in L/day: <input type="text" /></p> |

| - | <p id="substrate">Subtrate concentration before filter: <input type="text" /> | + | <p id="substrate">Subtrate concentration before filter in nM: <input type="text" /></p> |

| - | <p id="final">Desired substrate concentration after filter: <input type="text" /> | + | <p id="final">Desired substrate concentration after filter in nM: <input type="text" /></p> |

<p><input type="submit" value="Calculate number of rafts" /></p> | <p><input type="submit" value="Calculate number of rafts" /></p> | ||

<p id="result"></p> | <p id="result"></p> | ||

| Line 32: | Line 32: | ||

<html><div id="substrate"> | <html><div id="substrate"> | ||

<p id="enzyme">Select enzyme: <select> | <p id="enzyme">Select enzyme: <select> | ||

| - | <option | + | <option>EreB</option> |

<option>Laccase</option> | <option>Laccase</option> | ||

| - | <option>Custom</option> | + | <option selected="selected">Custom</option> |

</select></p> | </select></p> | ||

<p id="activity">Enter enzyme activity: <input type="text" />k<sub>cat</sub>/k<sub>M</sub></p> | <p id="activity">Enter enzyme activity: <input type="text" />k<sub>cat</sub>/k<sub>M</sub></p> | ||

Revision as of 19:58, 4 October 2013

Filter calculator

To simplify the testing of use cases and for the comfort of future users, we implemented a filter calculator. The filter calculator either calculates the number of remediation rafts needed to degrade a certain amount of pollutant, or it computes the residual subtrate concentration when a entered number of remediation rafts is used. If you choose one of our effectors (EreB or Laccase) the kinetic values determined by our data analysis will be used, otherwise you can enter the parameters of your own protein. For more information on how this is computed see the documentation below.

Calculate number of remediation rafts

Select enzyme:

Enter enzyme activity (kcat/kM) in M-1s-1:

Enter molecular mass in Da:

Flowrate in L/day:

Subtrate concentration before filter in nM:

Desired substrate concentration after filter in nM:

Calculate pollutant degradation

Select enzyme:

Enter enzyme activity: kcat/kM

Enter molecular mass: Da

Flowrate: L/day

Subtrate concentration before filter: nM

Number of remediation rafts:

Filter model

For this model we assume that the enzymes are secreted into the flowing water of the river or outflow of a waste water treatment plant. To determine the enzyme concentration we could achieve in this way, we questioned the experts of [http://www.greenovation.com Greenovation] (see our Expert council), a company using P. patens for the mass production of proteins for the pharmaceutical market. They told us, that in their experience fully grown moss produces 50-350 mg of protein per liter of liquid culture per day. For our computations we chose the conservative value of 100 mg per liter of culture per day.

Our remediation rafts (see our implementation page) have an area of slightly over 1 m2, so taking into account the additional density due to the sedentary growth on the felt, we estimated this to roughly equal a liquid culture of 10 cm height, giving a culture volume of 100 liters per raft.

The price per raft is (also on our implementation page) about 50 € including the setup. The optional Arduino controller providing live data on the current status of the filter, costs about 250 €, but you only need a single one for each filter location.

The enzymes produced in a day will be diluted in the amount of water flowing by in a day, so the enzyme concentration in the water is given by:

For the evolution of the substrate concentration we started with the well-known Michaelis-Menten formula and dropped the substrate concentration in the denominator, since the concentrations of the micro-pollutants found in the environment is always much smaller than the KM values of the proteins, so we have the differential equation

For simplicity we crudely estimated that the protein lasts for 24 hours in the water and then degrades completely. So using the enzyme concentration found above, we get the following formula for the final substrate concentration, when the number of rafts is given:

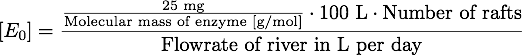

By inverting this we get the formula below, showing how many rafts are necessary to reduce the substrate concentration by a specified amount

Outlook

This model could easily be extended to incorporate further parameters such as the half-life of the protein in water. Also further characterizations of the proteins could be incorporated, in particular the dependency of the activity on the temperature, pH and salinity of the water.

Code

The code for this calculator can be found here.

"

"

AutoAnnotator:

Follow us:

Address:

iGEM Team TU-Munich

Emil-Erlenmeyer-Forum 5

85354 Freising, Germany

Email: igem@wzw.tum.de

Phone: +49 8161 71-4351