Team:Imperial College/Waste Degradation: SRF

From 2013.igem.org

| (90 intermediate revisions not shown) | |||

| Line 3: | Line 3: | ||

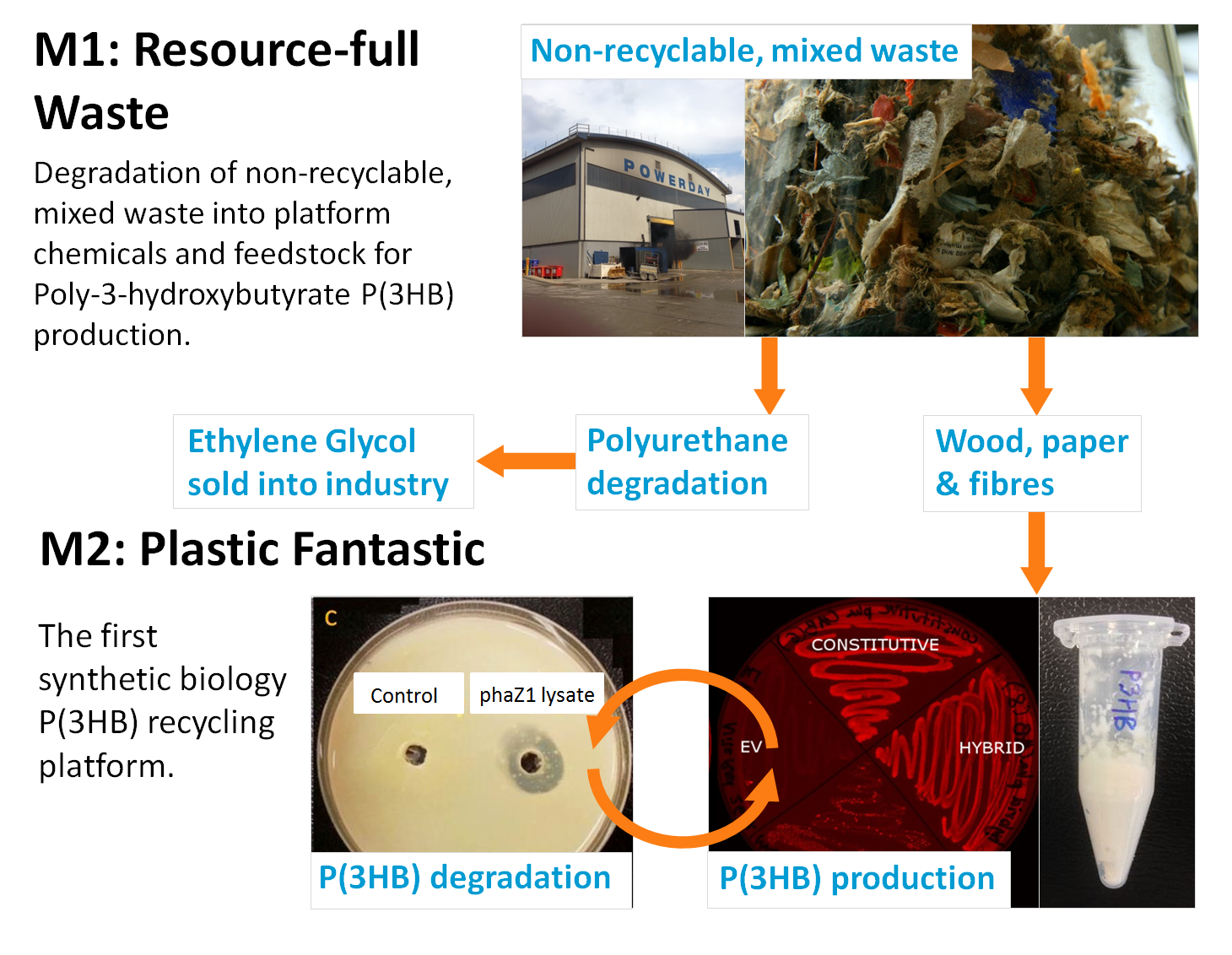

<h1>Module 1: Resource-full Waste</h1> | <h1>Module 1: Resource-full Waste</h1> | ||

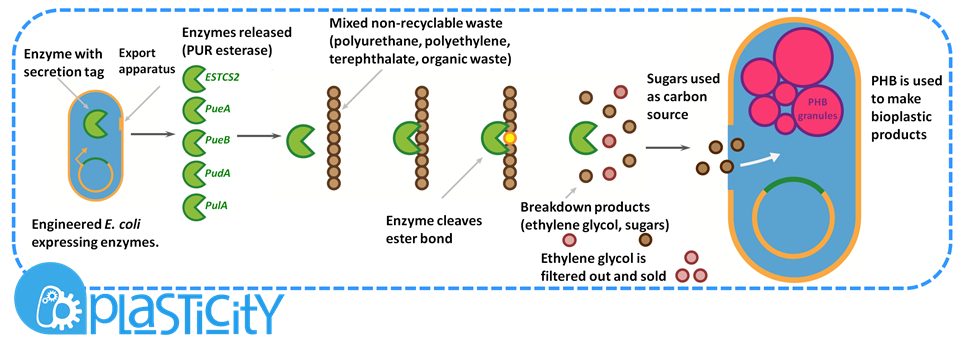

| - | [[File: | + | [[File:Mod1diagram.png|thumbnail|800px|center]] |

<b>Non-recyclable waste is sourced from a recycling centre, placed in a bioreactor with our M.A.P.L.E system which degrades the waste and synthesises the bioplastic P(3HB). Click the tabs to find out more</b> | <b>Non-recyclable waste is sourced from a recycling centre, placed in a bioreactor with our M.A.P.L.E system which degrades the waste and synthesises the bioplastic P(3HB). Click the tabs to find out more</b> | ||

| Line 23: | Line 23: | ||

<br> | <br> | ||

| - | <p>Waste from recovery facilities is a mixture of plastics and cellulosic rich biomass such as fibres and wood. The Resource-full waste module utilises | + | <p>Waste from recovery facilities is a mixture of plastics and cellulosic rich biomass such as fibres and wood. The Resource-full waste module utilises the large variety of materials organisms can naturally degrade to recycle the waste and to provide food for the production of the bioplastic poly-3-hydroxybutyrate, P(3HB). </p> |

<h4>Separating polyurethane and selling its breakdown products</h4> | <h4>Separating polyurethane and selling its breakdown products</h4> | ||

| - | <p>Certain enzymes have the ability to degrade plastics as a result of their evolutionary history, dealing with tough and highly variable substrates such as lignin. Various enzymes have been biobricked to deal with most of the major petrochemical plastics, except for polyurethane. Polyurethane is one of the plastic constituents of this mixed waste. We have designed biobricks containing naturally occurring polyurethane esterases (also known as PUR esterases) to break polyurethane down into its constituent chemicals of ethylene glycol and isocyanate. These valuable chemicals will be separated using specialised filters and sold back to industry.<p> | + | <p>Certain enzymes have the ability to degrade plastics as a result of their evolutionary history, dealing with tough and highly variable substrates such as lignin. Various enzymes have been biobricked to deal with most of the major petrochemical plastics, except for polyurethane. Polyurethane is one of the plastic constituents of this mixed waste. We have designed biobricks containing naturally occurring polyurethane esterases (also known as PUR esterases) to break polyurethane down into its constituent chemicals of ethylene glycol and poly(isocyanate). These valuable chemicals will be separated using specialised filters and sold back to industry.<p> |

| - | |||

| - | |||

| - | <p> | + | <h4>Using the residual material as a substrate for P(3HB) production</h4> |

| + | |||

| + | <p>The remaining organic portion of the mixed waste is used as a carbon source for P(3HB) production. P(3HB) is produced by organisms containing the pha CAB operon, originally found in soil bacteria such as <I>Ralstonia eutropha</I>. The operon contains three genes which are members of the pathway required to make P(3HB). P(3HB) is used as a storage molecule in the organisms which produce it. They do this when nutrients are limiting but when there is a plentiful carbon source.</p> | ||

| + | |||

| + | <p>P(3HB) is produced commercially by several companies. One of the crucial factors in whether production is economical or not is the efficiency of bioplastic production. We have hugely increased the efficiency of P(3HB) production; an important step in making our system feasible.</p> | ||

| + | |||

| + | <p>To scale up the production of P(3HB), our system would require large amounts of purified sugars. We would, therefore, hydrolyse the long polysaccharide components to release the sugars. This is a current industrial pre-treatment technique to allow the fermentation of ligno-cellulosic biomass.</p> | ||

| - | |||

</html> | </html> | ||

| - | [[File: | + | [[File:Overviewdiagram.png|800px|center]] |

<html> | <html> | ||

| Line 58: | Line 61: | ||

<h2 id="specification">Specification</h2> | <h2 id="specification">Specification</h2> | ||

| - | <p><b>1. | + | <p><b>1. Our bacteria should survive and grow in mixed waste</b></p> |

<p>In order for the bacteria to produce bioplastic from the mixed waste they first need to be able to use | <p>In order for the bacteria to produce bioplastic from the mixed waste they first need to be able to use | ||

it as a carbon source</p> | it as a carbon source</p> | ||

| - | <p><b>2. | + | <p><b>2. Our bacteria should secrete a functional polyurethane esterase</b></p> |

<p>To recover the resources from polyurethane in the mixed waste, the enzymes should secrete in an active form.</p> | <p>To recover the resources from polyurethane in the mixed waste, the enzymes should secrete in an active form.</p> | ||

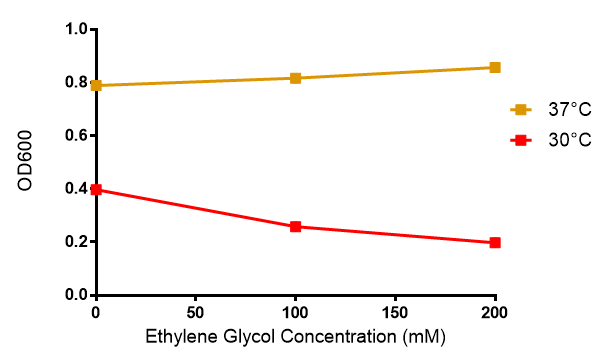

| - | <p><b>3. Our | + | <p><b>3. Our bacteria should be able to tolerate mixed waste degradation products, such as ethylene glycol</b></p> |

| - | <p>The products of | + | <p>The products of polyurethane degradation are toxic and so any bacteria growing with them must be able to survive to a concentration which will allow economical production of ethylene glycol. We have chosen a strain of <i>E.coli</i>-MG1655, which is resistant to ethylene glycol toxicity.</p> |

| - | <p><b>4. | + | <p><b>4. Our bacteria should produce P(3HB)</b></p> |

| - | <p><b>5. | + | <p><b>5. Our bacteria should produce P(3HB) from the mixed waste</b></p> |

</div> | </div> | ||

| Line 80: | Line 83: | ||

<img style="float: right;" IMG SRC="https://static.igem.org/mediawiki/2013/6/6c/Module1_3-13.jpg" ALT="testing" WIDTH=450 HEIGHT=450 POSITION=INLINE> | <img style="float: right;" IMG SRC="https://static.igem.org/mediawiki/2013/6/6c/Module1_3-13.jpg" ALT="testing" WIDTH=450 HEIGHT=450 POSITION=INLINE> | ||

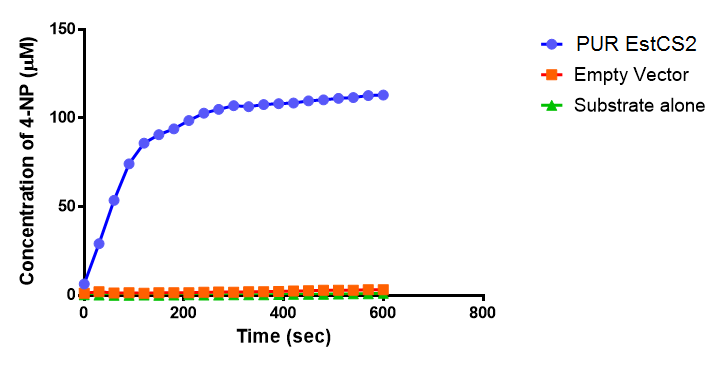

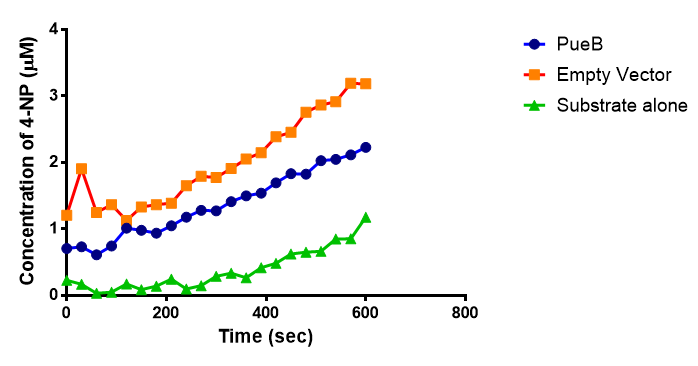

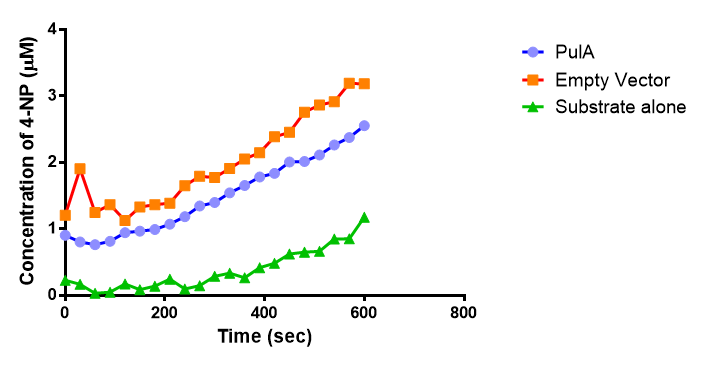

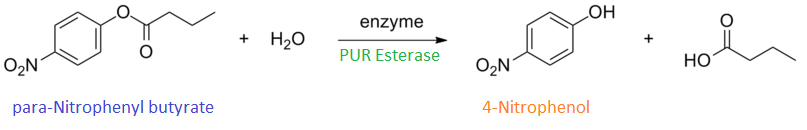

| - | <p> | + | <p>Lignin degrading microbial enzymes are capable of degrading plastics. Some previous iGEM teams have exploited this ability. We have built on their work and extended the plastic degradation capabilities of the synthetic biology community by improving polyurethane (PUR) degradation, as this has not been successfully achieved before. We have identified 5 PUR-esterase enzymes from the literature that are capable of catalyzing the below reaction.</p> |

<IMG SRC="https://static.igem.org/mediawiki/2013/9/9e/Pur_degradation.JPG" ALT="PUR molecular degradation" WIDTH=450 HEIGHT=450> | <IMG SRC="https://static.igem.org/mediawiki/2013/9/9e/Pur_degradation.JPG" ALT="PUR molecular degradation" WIDTH=450 HEIGHT=450> | ||

<br> | <br> | ||

| - | + | We have synthesised all of the genes in the below table and are testing them for expression in <i>E.coli</i>, secretion, activity and PUR degradation capabilities. Our ultimate design is to be able to control the relative levels of different enzymes in a waste-degrading bio-reactor, in order to adjust it to the composition of waste. We have, therefore, designed the expression constructs accordingly. Our models predict the degradation rate of polyurethane at the bioreactor scale. | |

| - | We have synthesised all of the genes in the below table and are testing them for expression in <i>E.coli</i>, secretion, activity and PUR | + | . |

| Line 138: | Line 141: | ||

</table> | </table> | ||

| - | |||

| + | <IMG SRC="https://static.igem.org/mediawiki/2013/8/86/PUR_biobricks_new.JPG" ALT="testing" WIDTH=400 HEIGHT=400> | ||

| + | |||

| + | </html> | ||

| + | <p><b>Secretion Strategy:</b> </p> | ||

| + | <p align="justify"><i>E.coli</i> is commonly used as a chassis in innovative iGEM projects that aim to prove a concept and make the case for a novel function in a biologically engineered machine. In our case, we aim to degrade and synthesise plastic and the degradation part of our system needs to be extracellular. There are many strategies for secretion. You can read about these on our [https://2013.igem.org/Team:Imperial_College/SecretionHelp Secretion Guide page] and find the corresponding biobricks and projects. If you are currently in the process of designing a Genetically Engineered Machine in E.coli, this page provides a good starting point to look for information.</p> | ||

| + | |||

| + | <p align="justify">We chose the pelB secretion tag as it has been demonstrated to work in many cases, sometimes with very high transport efficiency (1)(2). pelB has been used in iGEM projects for many years and is part of 50+ constructs. The UC-Davis team last year used it to secrete LC-Cutinase, a PET plastic degrading enzyme [http://parts.igem.org/Part:BBa_K936013 (BBa_K936013)] successfully, which is somewhat similar to our plastic-degrading enzymes.</p> | ||

| + | <html> | ||

| + | <p><b>Safety:</b> </p> | ||

| + | <p>We considered the safety aspects of using the PudA enzyme, since its sequences were originally from a Risk Group 2 (RG2) organism. We submitted our safety information to iGEM for review. <b>Safety forms were approved on October 2nd, 2013 by the iGEM Safety Committee.</b> We did not use the organism only the part itself and the final sequences were codon optimised for expression in E. coli, which included the elimination of the forbidden restriction sites.</p> | ||

| + | |||

| + | |||

| + | <p>References</p> | ||

| + | <ol class="reference"> | ||

| + | <li>Thanassi DG, Hultgren SJ. Multiple pathways allow protein secretion across the bacterial outer membrane. Current opinion in cell biology 2000;12(4) 420-430.</li> | ||

| + | <li>Sletta H, Tondervik A, Hakvag S, Aune TEV, Nedal A, Aune R, et al. The presence of N-terminal secretion signal sequences leads to strong stimulation of the total expression levels of three tested medically important proteins during high-cell-density cultivations of <i>E.coli</i>. Applied and Environmental Microbiology 2007;73(3) 906-912.</li> | ||

</div> | </div> | ||

| Line 149: | Line 167: | ||

| - | <p align="justify">Poly-3-hydroxybutyrate( | + | <p align="justify">Poly-3-hydroxybutyrate P(3HB) is a polyester which is naturally produced inside bacteria such as <i>Ralstonia eutropha</i>, where it accumulates as granules inside the cell. In its native bacteria it is produced as an energy store (1).It's properties as a plastic has gained it the attention of researchers and industrialists. In our system, the bacteria will take up organic molecules from waste and use them for P(3HB) production. </p> |

<IMG SRC="https://static.igem.org/mediawiki/parts/2/25/Module2555.png" ALT="testing" WIDTH=600 HEIGHT=600> | <IMG SRC="https://static.igem.org/mediawiki/parts/2/25/Module2555.png" ALT="testing" WIDTH=600 HEIGHT=600> | ||

| - | <p align="justify"> We have made | + | <p align="justify">We have made P(3HB) in <i>E.coli</i>, transferring three genes naturally found in <i>Ralstonia eutropha</i> into <i>E.coli</i> MG1655. These encode the three enzymes necessary for P(3HB) production; polyhydroxyalkanoate synthase(phaC), 3-ketothiolase(phaA) and acetoacetyl coenzyme A reductase(phaB). These are encoded by the pha CAB operon. We have altered the expression of these three genes to maximise the production of P(3HB) as high yields are required for it to be economically viable.</</p> |

<p><b>3-ketothiolase:</b></p> | <p><b>3-ketothiolase:</b></p> | ||

<IMG SRC="https://static.igem.org/mediawiki/2013/7/75/PhaA_reaction_diagram.jpg" ALT="testing" WIDTH=1000 HEIGHT=1000> | <IMG SRC="https://static.igem.org/mediawiki/2013/7/75/PhaA_reaction_diagram.jpg" ALT="testing" WIDTH=1000 HEIGHT=1000> | ||

| - | <p><b> | + | <p><b>Acetoacetyl coenzyme A reductase:</b></p> |

<IMG SRC="https://static.igem.org/mediawiki/2013/9/9c/PhaB_reaction_diagram.jpg" ALT="testing" WIDTH=1000 HEIGHT=1000> | <IMG SRC="https://static.igem.org/mediawiki/2013/9/9c/PhaB_reaction_diagram.jpg" ALT="testing" WIDTH=1000 HEIGHT=1000> | ||

| - | <p><b> | + | <p><b>Polyhydroxyalkanoate synthase:</b></p> |

<IMG SRC="https://static.igem.org/mediawiki/2013/d/df/PhaC_reaction_diagram.jpg" ALT="testing" WIDTH=1000 HEIGHT=1000> | <IMG SRC="https://static.igem.org/mediawiki/2013/d/df/PhaC_reaction_diagram.jpg" ALT="testing" WIDTH=1000 HEIGHT=1000> | ||

| Line 175: | Line 193: | ||

</html> | </html> | ||

| - | <p> We | + | <p>We used the pha CAB biobrick [http://parts.igem.org/Part:BBa_K934001 BBa_K934001] to produce P(3HB) which contains the native operon of <i>Ralstonia eutropha</i>. Inthe future we would like to see our system implemented at an industrial scale. This requires high yields to be economically viable. We created P(3HB) synthesis models to inform our experimental attempts to increase P(3HB) yield. We were especially interested to find out if up or down-regulation of any of the enzymes involved in the biosynthetic pathway could increase yields. To analyse this, we needed to know the reactions in the metabolic pathway and also the relative parameters of the enzymes and their dynamic relationships in order to identify bottlenecks in the flux of metabolites. The results from the metabolic model suggest that the amount of pha B is especially critical and increasing its level should give us more P(3HB). (Please see our modelling section for details.) To do this, we designed constructs with stronger promoters to up-regulate the expression of the operon. </p> |

| - | <p>We designed and constructed two new constructs for increased expression of the operon (including | + | <p>We designed and constructed two new constructs for increased expression of the operon (including pha B). The first construct uses the constitutive promoter [http://parts.igem.org/Part:BBa_J23104 J23104] and the [http://parts.igem.org/Part:BBa_B0034 RBS 0034] with a following scar site TACTAGAG in front of the ATG of the pha C gene. The second construct was designed as a hybrid promoter incorporating BBa_J23104 and the original promoter first, followed by the native promoter and RBS, due to recent results of high expression from a hybrid promoter[http://www.plosone.org/article/info%3Adoi%2F10.1371%2Fjournal.pone.0056321]. The region containing the native promoter and RBS is 352 nucleotides long and might contain important regulatory elements and therefore we were interested to test the hybrid construct in comparison to both the native and constitutive promoter configurations.</</p> |

https://static.igem.org/mediawiki/2013/6/60/PhaCAB_all_kinfds_of_parts.jpg | https://static.igem.org/mediawiki/2013/6/60/PhaCAB_all_kinfds_of_parts.jpg | ||

| Line 190: | Line 208: | ||

<div class="CollapsiblePanelTab" tabindex="0"><h4> Chassis Design: Tolerance to Waste </html><font size="1">▼</font size="1"><html></h4></div> | <div class="CollapsiblePanelTab" tabindex="0"><h4> Chassis Design: Tolerance to Waste </html><font size="1">▼</font size="1"><html></h4></div> | ||

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

| - | |||

</html> | </html> | ||

<p align="justify">We chose the MG1655 <i>E.coli</i> strain as chassis because it constitutively expresses genes that make it resistant to toxic waste degradation products, such as Ethylene glycol. | <p align="justify">We chose the MG1655 <i>E.coli</i> strain as chassis because it constitutively expresses genes that make it resistant to toxic waste degradation products, such as Ethylene glycol. | ||

| - | The [http://parts.igem.org/Part:BBa_K892010 | + | The [http://parts.igem.org/Part:BBa_K892010 aldA] and [http://parts.igem.org/Part:BBa_K892009 fucO] genes have an important role in decreasing the toxic effects of ethylene glycol by converting it into glycolaldehyde which is a link to the cell`s central metabolism. We have received these genes from the registry and future work could be to express these in <i>Bacillus</i> or cellulose-degrading organisms to make them tolerant as well. |

| + | </p> | ||

| + | https://static.igem.org/mediawiki/2013/8/8f/AldA_fucO_pathway.jpg | ||

<html> | <html> | ||

</div> | </div> | ||

</div> | </div> | ||

| - | |||

<div id="CollapsiblePaneldesign6" class="CollapsiblePanel"> | <div id="CollapsiblePaneldesign6" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0"><h4>Enzyme Secretion Strategy | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Enzyme Secretion Strategy </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

| - | |||

</html> | </html> | ||

| - | |||

| - | + | <p align="justify"><i>E.coli</i> is commonly used as a chassis in innovative iGEM projects that aim to prove a concept and make the case for a novel function in a biologically engineered machine. In our case, we aim to degrade and synthesise plastic and the degradation part of our system needs to be extracellular. There are many strategies for secretion. You can read about these on our [https://2013.igem.org/Team:Imperial_College/SecretionHelp Secretion Guide page] and find the corresponding biobricks and projects. If you are currently in the process of designing a Genetically Engineered Machine in E.coli, this page provides a good starting point to look for information.</p> | |

| - | <p align="justify"> | + | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | </p> | + | |

| - | < | + | <p align="justify">We chose the pelB secretion tag as it has been demonstrated to work in many cases, sometimes with very high transport efficiency (3). pelB has been used in iGEM projects for many years and is part of 50+ constructs. The UC-Davis team last year used it to secrete LC-Cutinase, a PET plastic degrading enzyme [http://parts.igem.org/Part:BBa_K936013(BBa_K936013)] successfully, which is somewhat similar to our plastic-degrading enzymes.</p> |

| - | < | + | <p>References</p> |

| - | < | + | <ol class="reference"> |

| - | < | + | <li>Economou A. Following the leader: bacterial protein export through the Sec pathway. Trends in microbiology 1999;7(8) 315-320.</li> |

| - | + | <li>Thanassi DG, Hultgren SJ. Multiple pathways allow protein secretion across the bacterial outer membrane. Current opinion in cell biology 2000;12(4) 420-430.</li> | |

| - | + | <li>Sletta H, Tondervik A, Hakvag S, Aune TEV, Nedal A, Aune R, et al. The presence of N-terminal secretion signal sequences leads to strong stimulation of the total expression levels of three tested medically important proteins during high-cell-density cultivations of <i>E.coli</i>. Applied and Environmental Microbiology 2007;73(3) 906-912.</li> | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | </ | + | |

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

</ol> | </ol> | ||

| Line 319: | Line 241: | ||

</div> | </div> | ||

</div> | </div> | ||

| + | |||

| + | |||

<div id="CollapsiblePaneldesign7" class="CollapsiblePanel"> | <div id="CollapsiblePaneldesign7" class="CollapsiblePanel"> | ||

| Line 335: | Line 259: | ||

</html> | </html> | ||

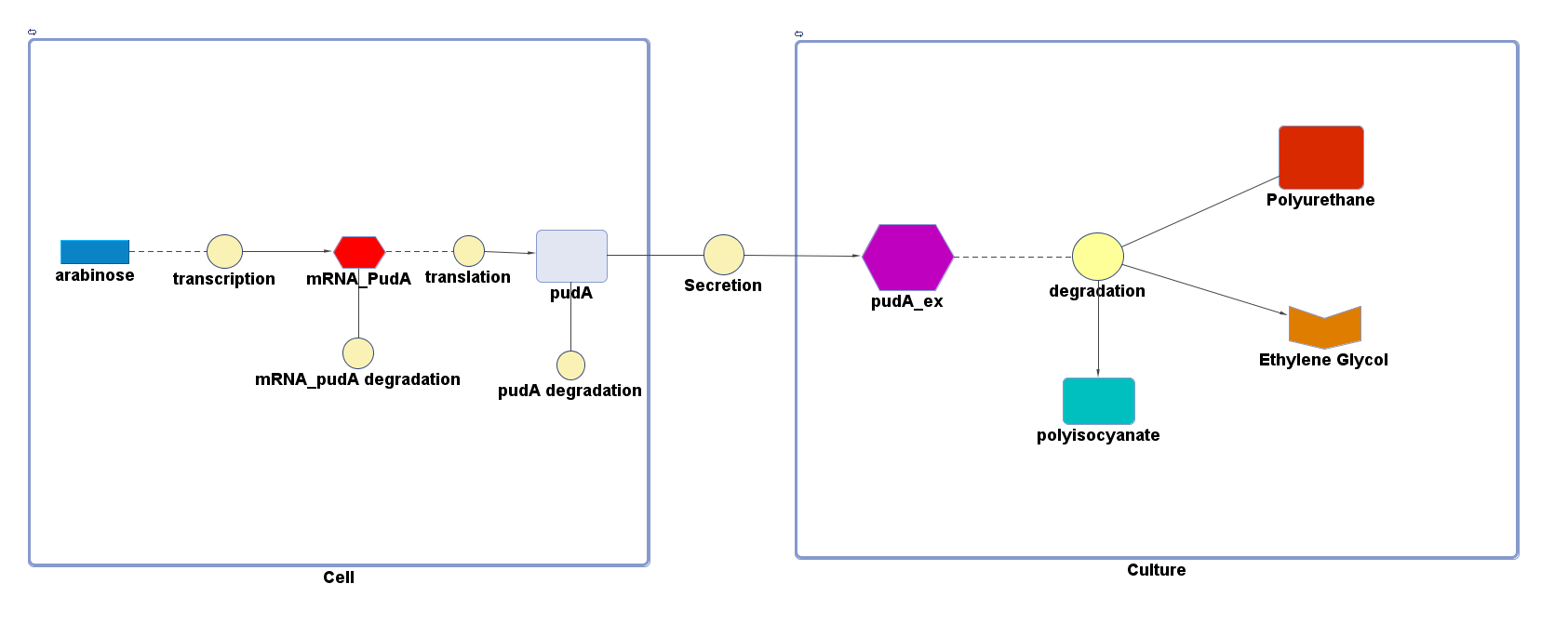

| - | <h4>What we | + | <h4>What we learnt from the PUR degradation model:</h4> |

*The model assisted the design of enzyme assays, in particular: | *The model assisted the design of enzyme assays, in particular: | ||

*The toxicity of the PUR degradation product, Ethylene glycol was taken into account in the modelling and it successfully determined the maximum tolerance of the system. | *The toxicity of the PUR degradation product, Ethylene glycol was taken into account in the modelling and it successfully determined the maximum tolerance of the system. | ||

*Ethylene glycol toxicity assays were carried out in the wet lab and were designed according to the results from our model. | *Ethylene glycol toxicity assays were carried out in the wet lab and were designed according to the results from our model. | ||

| - | <h4>What we | + | <h4>What we learnt from the P(3HB) synthesis model:</h4> |

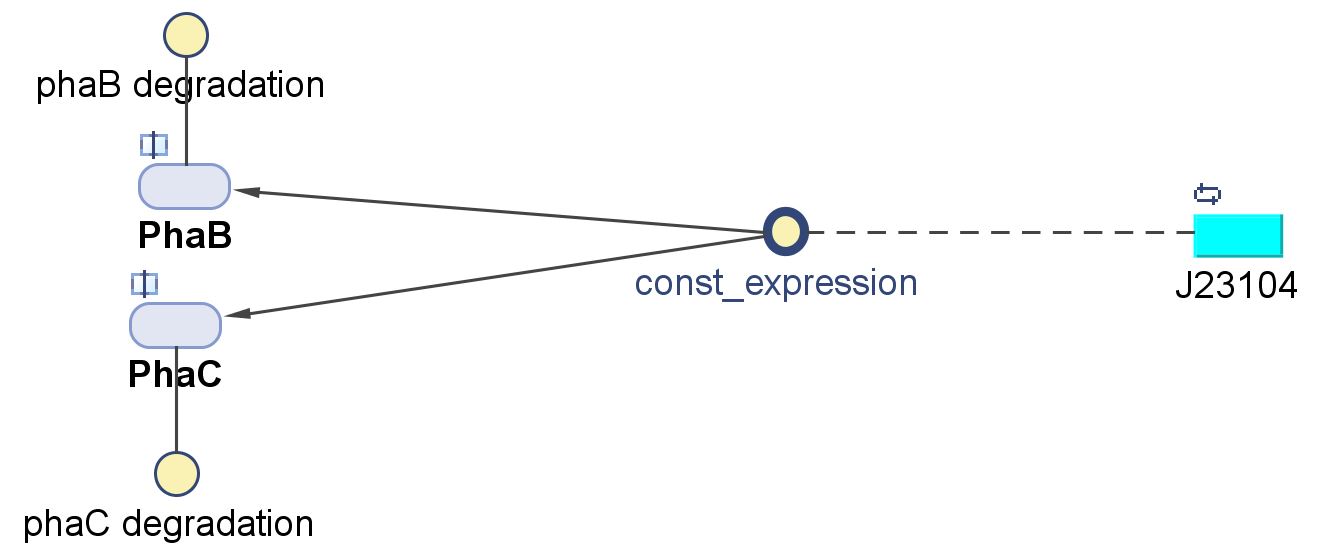

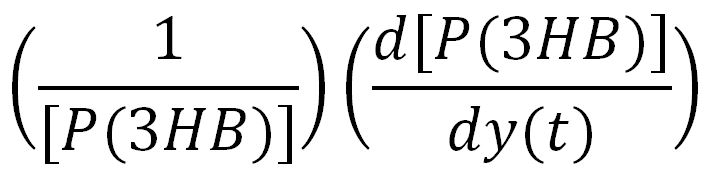

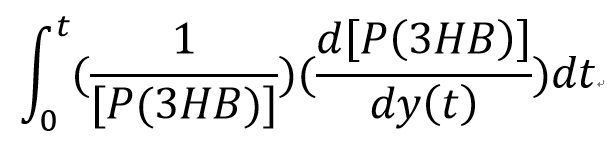

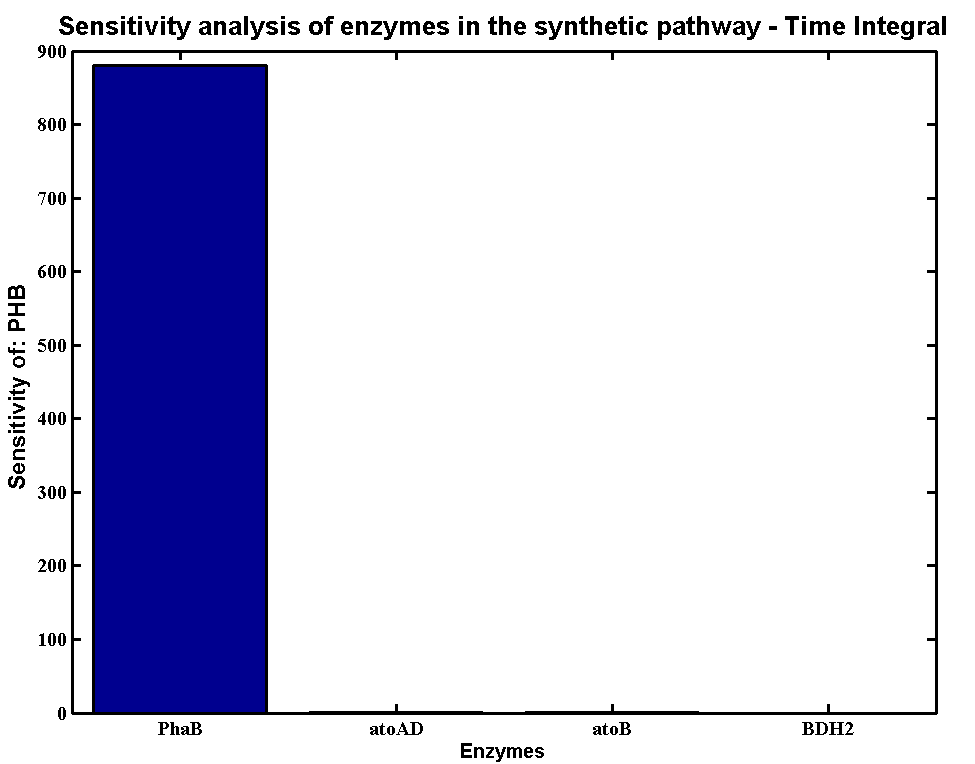

| - | * Scanning concentration of | + | * Scanning concentration of pha B and sensitivity analysis showed that increasing the concentration of pha B would increase the production rate of P(3HB) in our engineered 'E.coli'. |

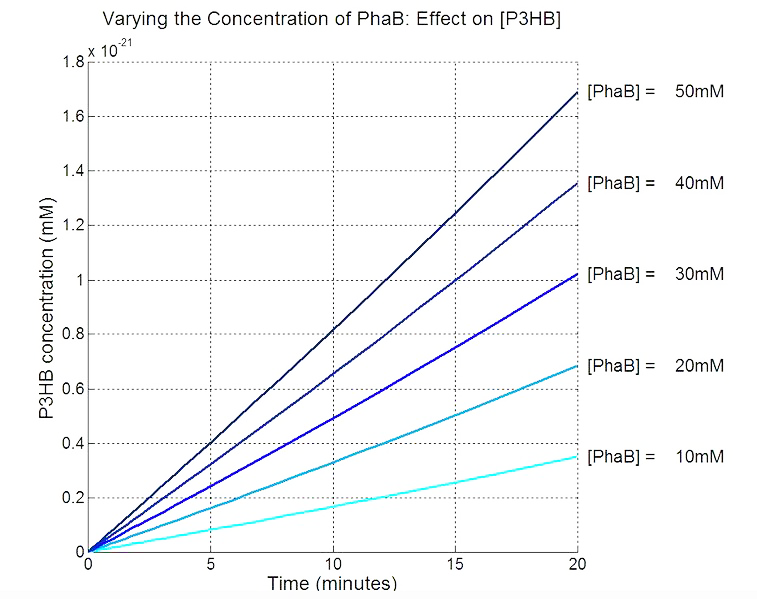

| - | * Simulations showed that the constitutive promoter J23104 could lead to a higher expression of | + | * Simulations showed that the constitutive promoter J23104 could lead to a higher expression of pha B than the native promoter. As a result the Wet lab team designed and built [http://parts.igem.org/Part:BBa_K1149051 BBa_K1149051], which significantly increased bioplastic production. |

* Results from the metabolic model suggested that the synthesis of P(3HB) would be accompanied by a drop of ATP over time and hence allowed us to identify potential limitations of our engineered system. This is important for the [https://2013.igem.org/Team:Imperial_College/Industrial_Implementation Industrial Implementation of our system.] | * Results from the metabolic model suggested that the synthesis of P(3HB) would be accompanied by a drop of ATP over time and hence allowed us to identify potential limitations of our engineered system. This is important for the [https://2013.igem.org/Team:Imperial_College/Industrial_Implementation Industrial Implementation of our system.] | ||

| Line 353: | Line 277: | ||

<p align="justify"> | <p align="justify"> | ||

| - | The efficiencies for | + | The efficiencies for polyurethane (PUR) degradation and ethylene glycol production are important for the performance of our system. We built a mathematical and deterministic model that is based on MATLAB extension Simbiology for polyurethane degradation. The model contains the kinetic properties of degradation enzymes that are helpful for the design of assays. As we scaled up the initial concentrations of all substrates to meet the conditions for a bio-reactor, the model can provide preliminary simulations and predictions for the <b>MAPLE</b> system. </p> |

<h4>Design</h4> | <h4>Design</h4> | ||

<h5>Objective</h5> | <h5>Objective</h5> | ||

| Line 359: | Line 283: | ||

<p>1. The model should contain the gene expression model of the degradation enzymes because the enzyme concentration determines the rate of plastic degradation. In our case for PUR degradation, we used [http://parts.igem.org/Part:BBa_K206000 pBAD strong promoter K206000] for most enzymes. We built the gene expression model based on inducible pBAD promoter, which gene expression rate can be regulated by inducer concentration.</p> | <p>1. The model should contain the gene expression model of the degradation enzymes because the enzyme concentration determines the rate of plastic degradation. In our case for PUR degradation, we used [http://parts.igem.org/Part:BBa_K206000 pBAD strong promoter K206000] for most enzymes. We built the gene expression model based on inducible pBAD promoter, which gene expression rate can be regulated by inducer concentration.</p> | ||

<p>2. The model should show the efficiency of the enzyme secretion to the culture from the cells. It's also important because the enzyme concentration in the culture depends on it. Here we used pelB secretion tag for most enzymes in order to achieve a high efficiency.</p> | <p>2. The model should show the efficiency of the enzyme secretion to the culture from the cells. It's also important because the enzyme concentration in the culture depends on it. Here we used pelB secretion tag for most enzymes in order to achieve a high efficiency.</p> | ||

| - | <p>3. The model basically | + | <p>3. The model basically predicts how long will take to degrade a known concentration of soluble polyurethane. It is assumed that the enzyme in our assays has the same kinetic properties as the enzyme used in the literature. The model can suggest a suitable concentration of the plastic to use in order to get good results from the assays. </p> |

| - | <p>4. It is known that ethylene glycol is toxic to E.coli. | + | <p>4. It is known that ethylene glycol is toxic to <i>E.coli</i>. It has, however, no clear effect on the growth of our MG1655 strain when the concentration of ethylene glycol is below 200 mM. The model, therefore, should suggest a safe range of polyurethane concentration to avoid a high concentration (>200mM) of ethylene glycol produced. </p> |

<h4>The Model</h4> | <h4>The Model</h4> | ||

<p align="justify">Polyurethane (PUR) degradation involves 5 different degradation enzymes:</p> | <p align="justify">Polyurethane (PUR) degradation involves 5 different degradation enzymes:</p> | ||

| Line 401: | Line 325: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| - | <p> | + | <p>4 of the 5 enzymes are not well characterised before, so we could't find enough kinetic data from the literature. The only well-characterised PUR degradation enzyme PudA is used in the model as an illustration of all PUR degradation enzymes. The model will be more complete when the kinetic data of the other enzymes are defined. The finished PUR degradation model is shown as below: </p> |

[[File:PurModel.png]] | [[File:PurModel.png]] | ||

<p>There are two compartments which represents cells and the culture from left to right. The "cell" compartment contains the gene expression module whereas the "culture" compartment contains the degradation module. The "secretion" block that connects two compartments is the secretion module. </p> | <p>There are two compartments which represents cells and the culture from left to right. The "cell" compartment contains the gene expression module whereas the "culture" compartment contains the degradation module. The "secretion" block that connects two compartments is the secretion module. </p> | ||

| Line 435: | Line 359: | ||

<th>d<sub>mRNA</sub></th> | <th>d<sub>mRNA</sub></th> | ||

<td>mRNA degradation rate</td> | <td>mRNA degradation rate</td> | ||

| - | <td>0. | + | <td>0.035</td> |

<td>1/min</td> | <td>1/min</td> | ||

| - | + | <td>[http://jb.asm.org/content/189/23/8746.full]</td> | |

| - | <td> | + | <td>There is no active degradation pathway and that dilution is the dominant way by which it degrades. Rate = ln2/doubling time, where doubling time of strain MG1655 = 20min. Assuming steady-state growth in LB broth as presented in paper. rate = ln2/20 = 0.035/min</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

<th>d<sub>protein</sub></th> | <th>d<sub>protein</sub></th> | ||

<td>Protein degradation rate</td> | <td>Protein degradation rate</td> | ||

| - | <td>0. | + | <td>0.035</td> |

<td>1/min</td> | <td>1/min</td> | ||

<td>[http://jb.asm.org/content/189/23/8746.full]</td> | <td>[http://jb.asm.org/content/189/23/8746.full]</td> | ||

| - | <td>There is no active degradation pathway and that dilution is the dominant way by which | + | <td>There is no active degradation pathway and that dilution is the dominant way by which it degrades. Rate = ln2/doubling time, where doubling time of strain MG1655 = 20min. Assuming steady-state growth in LB broth as presented in paper. rate = ln2/20 = 0.035/min</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 462: | Line 386: | ||

<td>Initial: 0.008</td> | <td>Initial: 0.008</td> | ||

<td>mM</td> | <td>mM</td> | ||

| - | <td></td> | + | <td>-</td> |

| - | <td></td> | + | <td>-</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 509: | Line 433: | ||

<h4>PUR degradation module</h4> | <h4>PUR degradation module</h4> | ||

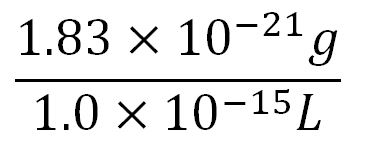

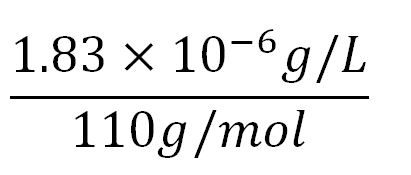

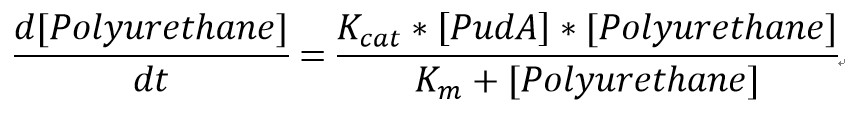

<p>The reaction equation of the PUR degradation is:</p> | <p>The reaction equation of the PUR degradation is:</p> | ||

| - | [Polyurethane]+[PudA]= | + | [Polyurethane]+[PudA]= 4 [ethylene glycol] + 4 [polyisocyanate] + [PudA] |

<p><b>Assumptions:</b></p> | <p><b>Assumptions:</b></p> | ||

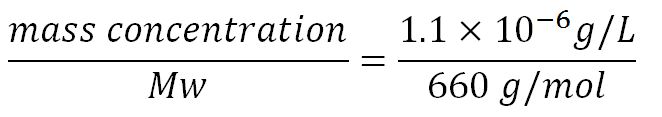

| - | <p>We assumed 1 mole of polyurethane dispersion can produce | + | <p>We assumed 1 mole of polyurethane dispersion can produce 4 moles of ethylene glycol. </p> |

| - | <p>The molecular weight of a single polyurethane monomer is 470 g/mol whereas the molecular weight of the polyurethane dispersion is around 2000 g/mol.[http://www.polyurethanes.basf.de/pu/solutions/en/content/group/Arbeitsgebiete_und_Produkte/Grundprodukte/Lupraphen-Produktuebersicht_Gewicht]Therefore, the short-chain polyurethane consists approximately | + | <p>The molecular weight of a single polyurethane monomer is 470 g/mol whereas the molecular weight of the polyurethane dispersion is around 2000 g/mol.[http://www.polyurethanes.basf.de/pu/solutions/en/content/group/Arbeitsgebiete_und_Produkte/Grundprodukte/Lupraphen-Produktuebersicht_Gewicht]Therefore, the short-chain polyurethane consists approximately 4 monomers. 4 molecules of ethylene glycol will be produced by degrading one chain of polymer.</p> |

<p>We also assumed a simple Michaelis-Menten mechanism for PudA</p> | <p>We also assumed a simple Michaelis-Menten mechanism for PudA</p> | ||

[[File:MMPUR.png|400px|centre]] | [[File:MMPUR.png|400px|centre]] | ||

| Line 550: | Line 474: | ||

<p>The efficiency of <b>Secretion</b> is assumed to be 90% secretion over 2 hours.[http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1251600/] The rate of secretion in the model is therefore:</p> | <p>The efficiency of <b>Secretion</b> is assumed to be 90% secretion over 2 hours.[http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1251600/] The rate of secretion in the model is therefore:</p> | ||

<p>rate of secretion = 0.9[concentration of PudA]/120 (mM/mins) </p> | <p>rate of secretion = 0.9[concentration of PudA]/120 (mM/mins) </p> | ||

| - | <h4>Simulation Results</h4> | + | <h4>Simulation Results and Industrial Implementation</h4> |

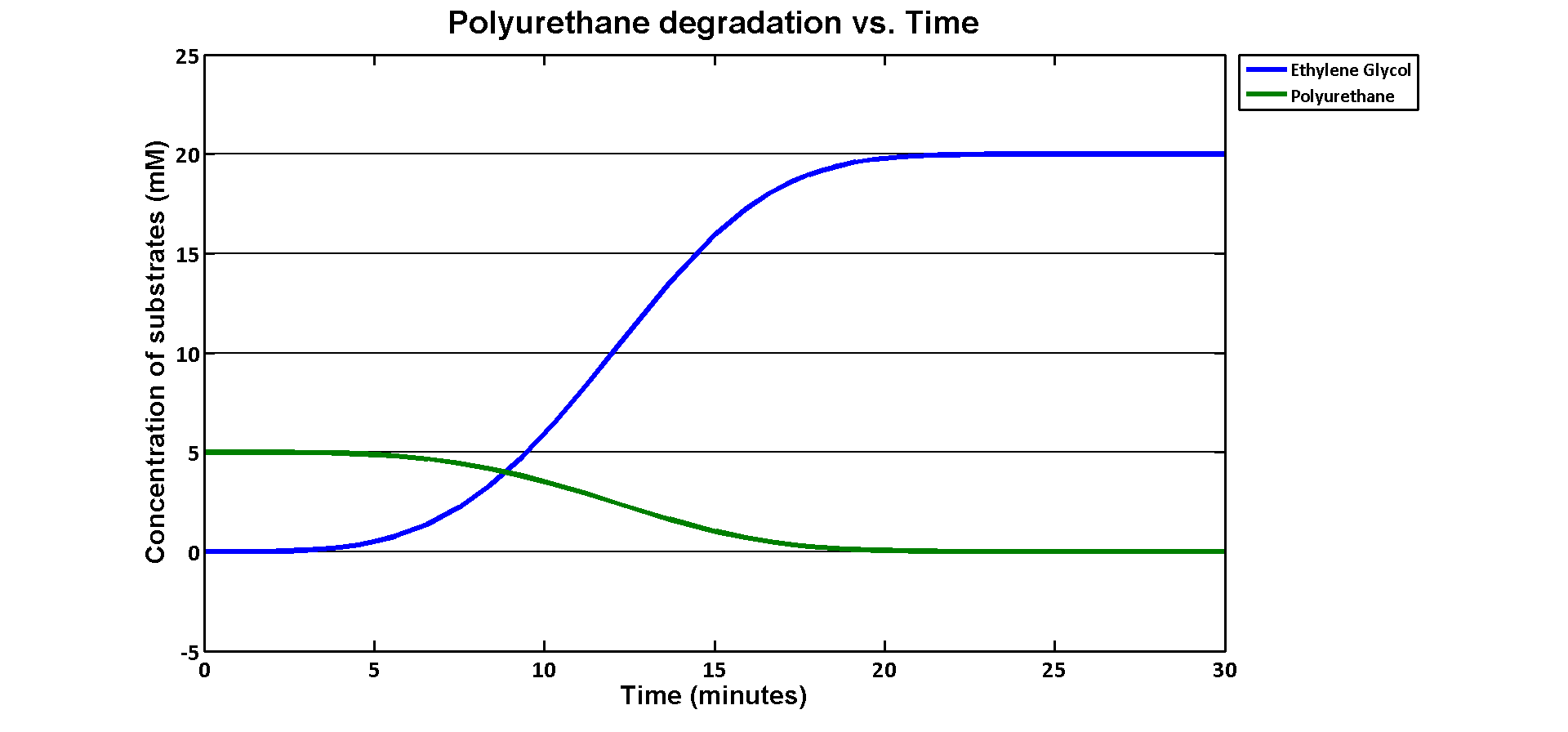

| - | <p> | + | <p>The simulation result we worked out is especially related to the industrial degradation SRF which we aim to achieve a high degradation efficiency. According to the [https://2013.igem.org/Team:Imperial_College/Industrial_Implementation data] we estimated for the percentage Polyurethane in SRF, we have about 5% Polyurethane contained in the waste. Therefore, in the model, we assumed 50g of polyurethane in 1kg of SRF based on the estimation. If we put 1kg of waste into a 5L bioreactor, the approximate concentration of polyurethane would be 5mM. Here is the simulation result: </p> |

| - | [[File:PURgraph.png| | + | [[File:PURgraph.png|1000px|centre]] |

| - | <p> | + | <p>The modelling result shows that we can efficiently degrade Polyurethane in SRF even in industrial scale. 5mM of polyurethane dispersion can be efficiently degraded in 15 mins. The final concentration of ethylene glycol we produced would be 20 mM that is under the toxicity limitation, this proves that our bio-reactor can maintain the efficiency without the toxicity effects. </p> |

<p>As for the implementation of MAPLE system, the polyurethane degradation enzymes in our system are very efficient. Therefore, we need an efficient filter which removing ethylene glycol from the system. </p> | <p>As for the implementation of MAPLE system, the polyurethane degradation enzymes in our system are very efficient. Therefore, we need an efficient filter which removing ethylene glycol from the system. </p> | ||

<html> | <html> | ||

| Line 569: | Line 493: | ||

</html> | </html> | ||

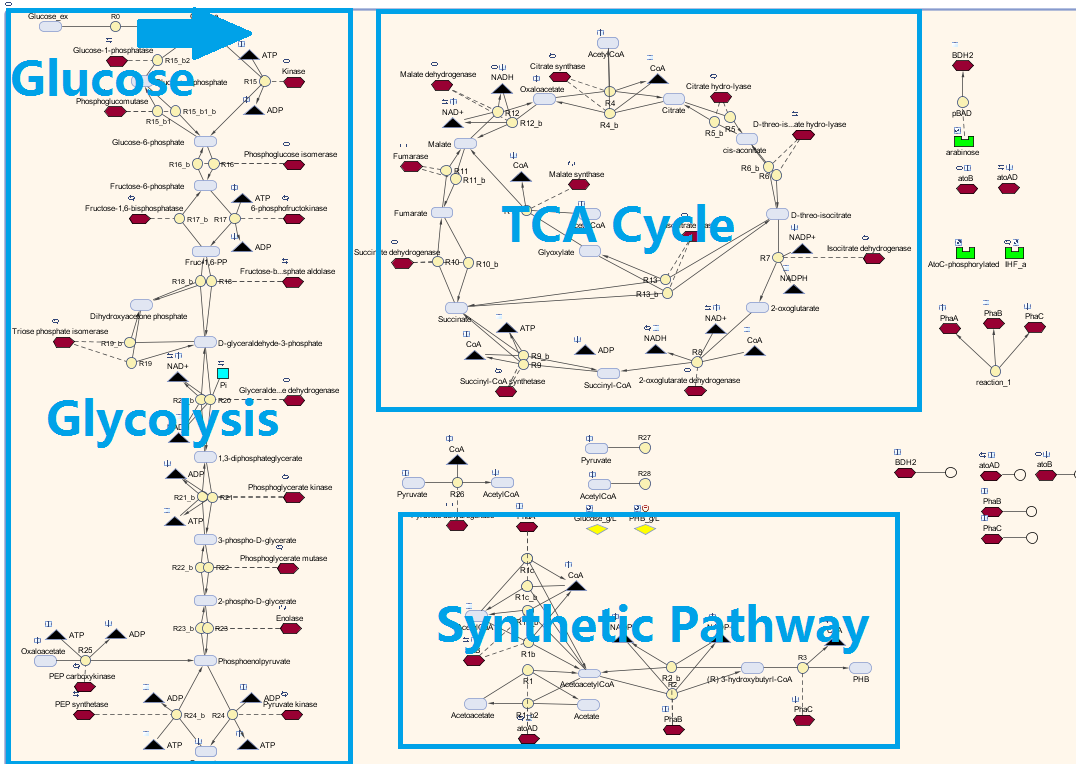

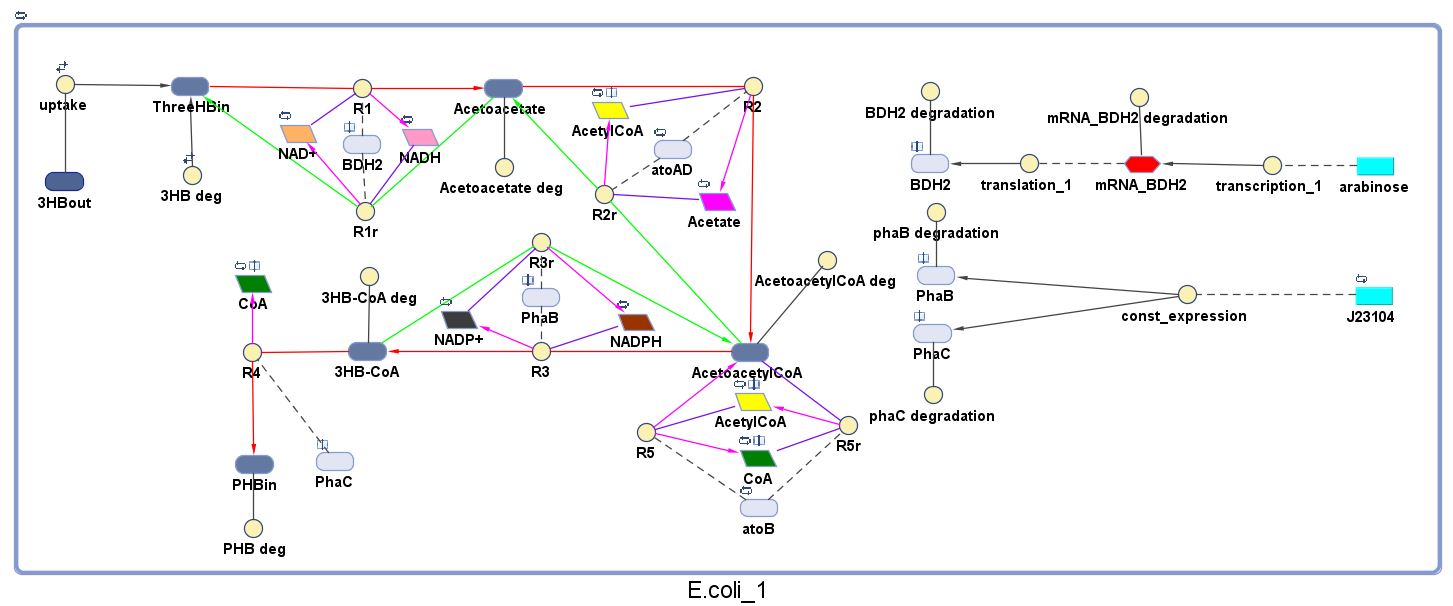

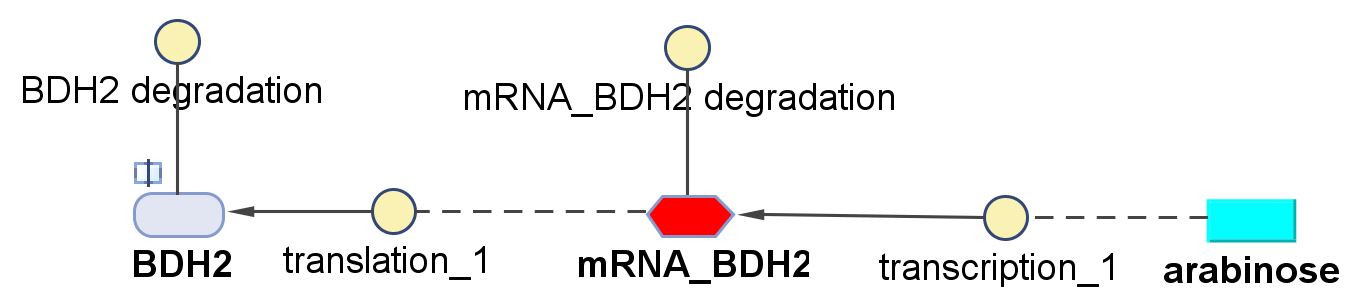

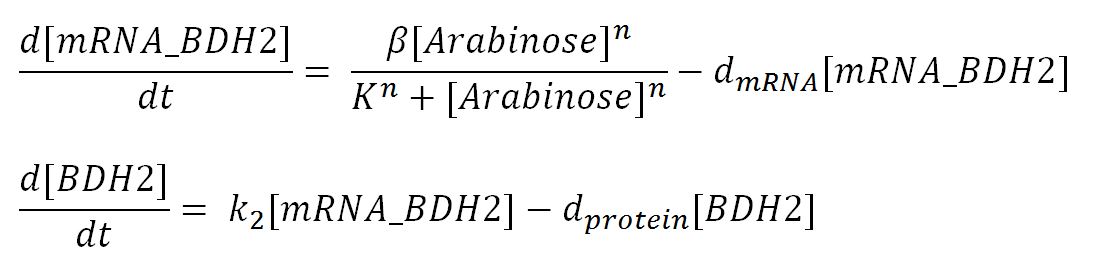

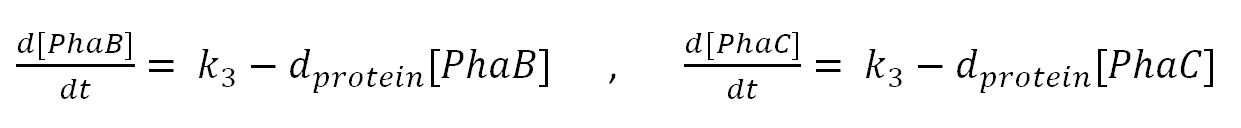

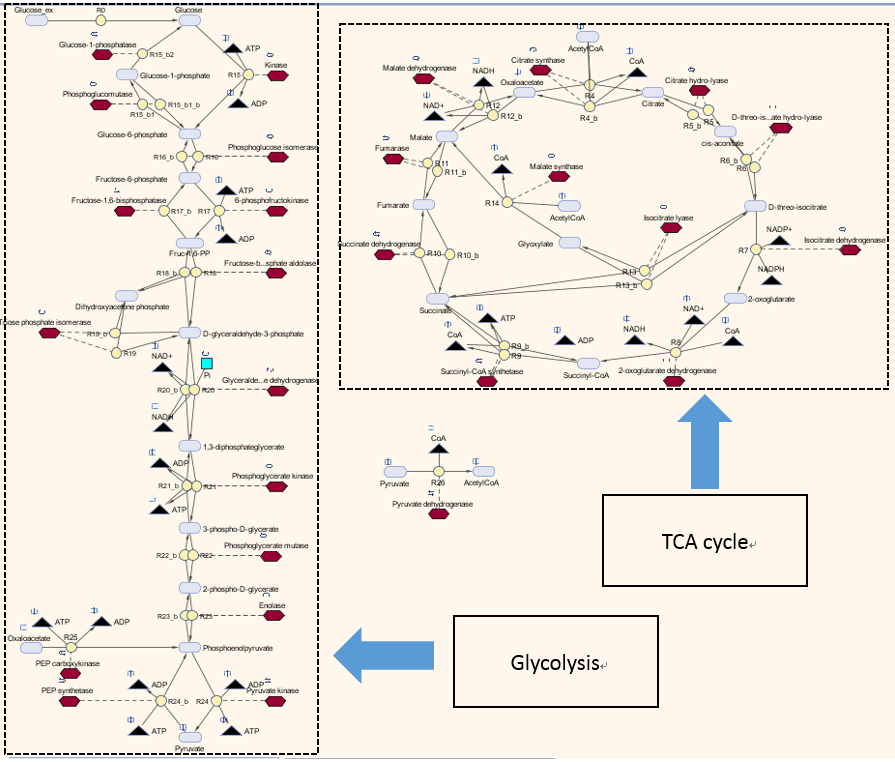

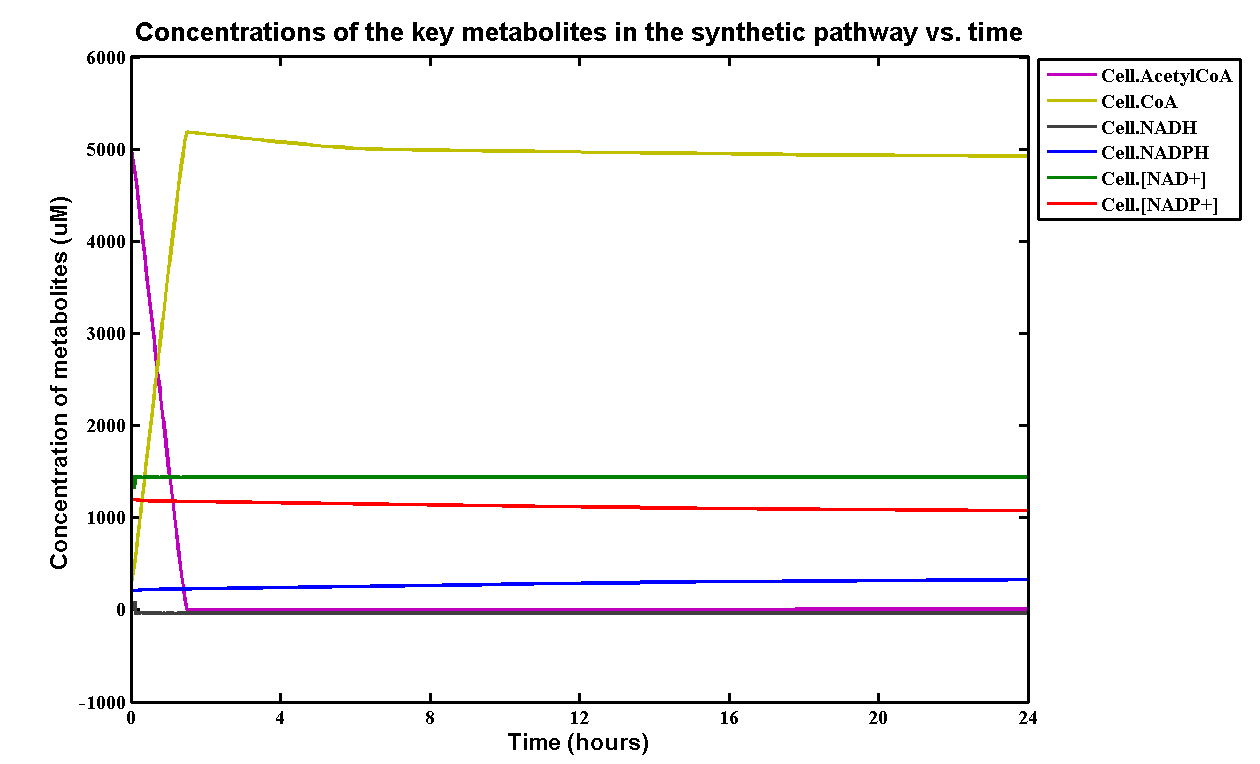

| - | This section is about modelling the plastic-synthesising <i>E.coli</i> developed in our project. The plastic that this module synthesises is the bioplastic poly-3-hydroxybutyrate, also known as P(3HB). The content below shows the process of building, designing and | + | This section is about modelling the plastic-synthesising <i>E.coli</i> developed in our project. The plastic that this module synthesises is the bioplastic poly-3-hydroxybutyrate, also known as P(3HB). The content below shows the process of building, designing and optimising the model. Also, the considerations, assumptions and limitations will be discussed. |

<p align="justify"> | <p align="justify"> | ||

The model was built and simulated in Simbiology, a Matlab package designed for modelling biological systems. In our model we have a compartment (labelled "<i>E.coli</i>_1") that represents our engineered cell. The compartment contains the reactions and species that interact with the polymer synthesis pathway. | The model was built and simulated in Simbiology, a Matlab package designed for modelling biological systems. In our model we have a compartment (labelled "<i>E.coli</i>_1") that represents our engineered cell. The compartment contains the reactions and species that interact with the polymer synthesis pathway. | ||

</p> | </p> | ||

| - | + | <p>Here is our model for P(3HB) synthesis. It is part of module 1, this model uses glucose from waste as the input. Here we have the phaCAB operon, which convertsthe metabolite acetyl-coA into poly-3-hydroxybutyrate. We integrated our synthetic pathway into the metabolic pathway. This allowed us to quantitatively predict the P(3HB) production over time. More details about the metabolic model can be found in [https://2013.igem.org/Team:Imperial_College/BioPlastic_Recycling:_PHB Module 2]. </p> | |

| + | [[File:Glucose_Pathway.png|centre|800px]] | ||

| + | <p>Firstly, consider the model concerning the synthetic pathway. This model does not take into account the existence of the metabolic pathway present within the bacteria. The synthetic pathway is mainly used for a sensitivity analysis by assuming minimum interference to the cell metabolism. The pathway is rearranged for clarity. </p> | ||

<p align="justify"> | <p align="justify"> | ||

The pathways on the right half of the cell are genetic expressions of the 3 enzymes involved in the plastic synthesis pathway. The pathways on the left represent the actual P(3HB) production pathway. | The pathways on the right half of the cell are genetic expressions of the 3 enzymes involved in the plastic synthesis pathway. The pathways on the left represent the actual P(3HB) production pathway. | ||

| Line 583: | Line 509: | ||

<p align="justify"> | <p align="justify"> | ||

| - | As can be seen in the | + | As can be seen in the Key (above), the yellow, solid circle represents a reaction object and for each object parameter the following needs to be specified for the simulation to work: |

</p> | </p> | ||

*Rate equation or kinetic law (e.g. mass action, Michaelis-Menten etc.) | *Rate equation or kinetic law (e.g. mass action, Michaelis-Menten etc.) | ||

| Line 590: | Line 516: | ||

*Value and units for each parameter | *Value and units for each parameter | ||

<p align="justify"> | <p align="justify"> | ||

| - | Simbiology will then use | + | Simbiology will then use an ODE solver (ode15 or sundial) to solve these ODEs and give a plot of the specified output(s) (concentration level of a species over time, for instance). |

</p> | </p> | ||

| + | *Note that 3HB deg, Acetoacetate deg, AcetoacetylCoA deg and 3HB-CoA deg are degradation rates (all = 0.035/min, please see assumptions below) of the corresponding species formed along the P(3HB) synthesis pathway. | ||

<html> | <html> | ||

</div> | </div> | ||

| Line 656: | Line 583: | ||

<th>d<sub>mRNA</sub></th> | <th>d<sub>mRNA</sub></th> | ||

<td>mRNA degradation rate</td> | <td>mRNA degradation rate</td> | ||

| - | <td>0. | + | <td>0.035</td> |

<td>1/min</td> | <td>1/min</td> | ||

| - | + | <td>[http://jb.asm.org/content/189/23/8746.full]</td> | |

| - | <td> | + | <td>There is no active degradation pathway and that dilution is the dominant way by which it degrades. Rate = ln2/doubling time, where doubling time of strain MG1655 = 20min. Assuming steady-state growth in LB broth as presented in paper. rate = ln2/20 = 0.035/min</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

<th>d<sub>protein</sub></th> | <th>d<sub>protein</sub></th> | ||

<td>Protein degradation rate</td> | <td>Protein degradation rate</td> | ||

| - | <td>0. | + | <td>0.035</td> |

<td>1/min</td> | <td>1/min</td> | ||

| - | + | <td>[http://jb.asm.org/content/189/23/8746.full]</td> | |

| - | <td>There is no active degradation pathway and that dilution is the dominant way by which | + | <td>There is no active degradation pathway and that dilution is the dominant way by which it degrades. Rate = ln2/doubling time, where doubling time of strain MG1655 = 20min. Assuming steady-state growth in LB broth as presented in paper. rate = ln2/20 = 0.035/min</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 775: | Line 702: | ||

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

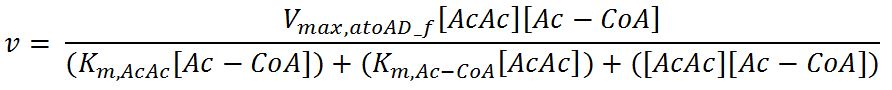

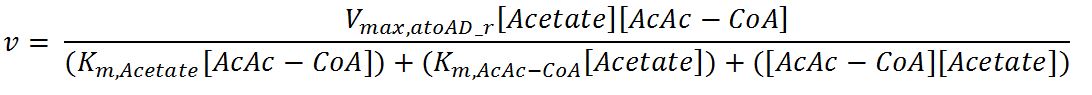

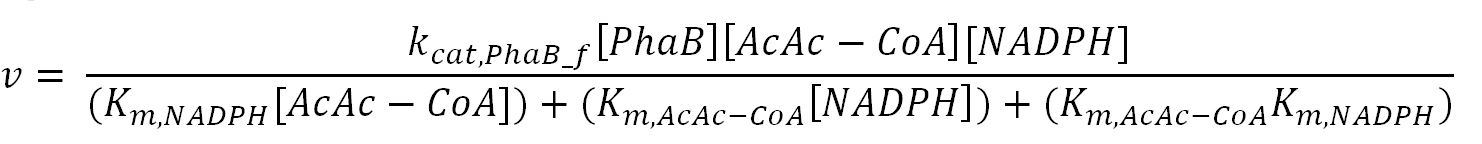

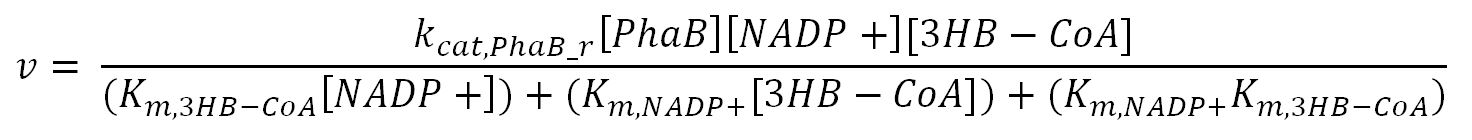

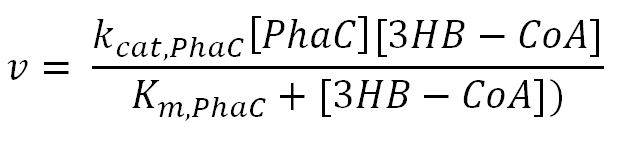

| + | *Note: | ||

| + | **v = velocity of reaction | ||

| + | **Ac-CoA = acetyl-CoA | ||

| + | **AcAc-CoA = Acetoacetyl-CoA | ||

| + | **AcAc = acetoacetate | ||

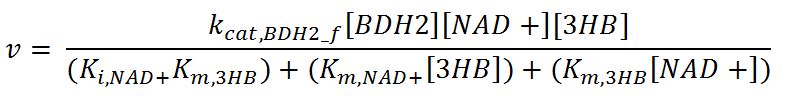

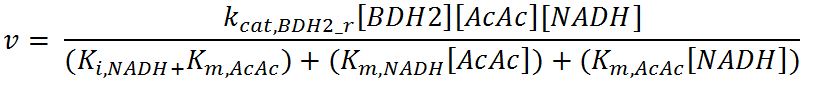

<h4>BDH2 (3-hydroxybutyrate dehydrogenase)</h4> | <h4>BDH2 (3-hydroxybutyrate dehydrogenase)</h4> | ||

| Line 829: | Line 761: | ||

<td>mM</td> | <td>mM</td> | ||

<td>[http://jb.oxfordjournals.org/content/early/2009/01/03/jb.mvn186.full.pdf]</td> | <td>[http://jb.oxfordjournals.org/content/early/2009/01/03/jb.mvn186.full.pdf]</td> | ||

| - | <td>Values in paper reference | + | <td>Values in paper reference</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 837: | Line 769: | ||

<td>mM</td> | <td>mM</td> | ||

<td>[http://jb.oxfordjournals.org/content/early/2009/01/03/jb.mvn186.full.pdf]</td> | <td>[http://jb.oxfordjournals.org/content/early/2009/01/03/jb.mvn186.full.pdf]</td> | ||

| - | <td> | + | <td>Values in paper reference</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 845: | Line 777: | ||

<td>mM</td> | <td>mM</td> | ||

<td>[http://jb.oxfordjournals.org/content/early/2009/01/03/jb.mvn186.full.pdf]</td> | <td>[http://jb.oxfordjournals.org/content/early/2009/01/03/jb.mvn186.full.pdf]</td> | ||

| - | <td> | + | <td>Values in paper reference</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 873: | Line 805: | ||

<tr> | <tr> | ||

<th>[3HB]</th> | <th>[3HB]</th> | ||

| - | <td> | + | <td>Intracellular concentration of 3HB</td> |

| - | <td> | + | <td>6.4x10<sup>-14</sup></td> |

<td>mM</td> | <td>mM</td> | ||

| - | <td> | + | <td>-</td> |

| - | <td> | + | <td>External concentration of 3HB assumed to be 0.01g. This is shared by 1.5x10<sup>12</sup> cells. Therefore, one cell has 0.01/1.5x10<sup>12</sup> = 6.7x10<sup>-15</sup> g. To convert it into mol/L: mass of 3HB/molar mass of 3HB = 6.7x10<sup>-15</sup>/104.1 = 6.4x10<sup>-17</sup> M = 6.4x10<sup>-14</sup> mM</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 980: | Line 912: | ||

<td>Concentration of AcAc-CoA</td> | <td>Concentration of AcAc-CoA</td> | ||

<td>initial: 1.0x10<sup>-13</sup></td> | <td>initial: 1.0x10<sup>-13</sup></td> | ||

| + | <td>mM</td> | ||

| + | <td>see section 2.5 "Initial concentrations of metabolites"</td> | ||

| + | <td>see section 2.5 "Initial concentrations of metabolites"</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <th>[Ac-CoA]</th> | ||

| + | <td>Concentration of Ac-CoA</td> | ||

| + | <td>initial: 1.0x10<sup>-14</sup></td> | ||

<td>mM</td> | <td>mM</td> | ||

<td>see section 2.5 "Initial concentrations of metabolites"</td> | <td>see section 2.5 "Initial concentrations of metabolites"</td> | ||

| Line 1,054: | Line 994: | ||

<td>-</td> | <td>-</td> | ||

<td>mM</td> | <td>mM</td> | ||

| - | <td></td> | + | <td>-</td> |

| - | <td></td> | + | <td>-</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 1,111: | Line 1,051: | ||

<td>1/min</td> | <td>1/min</td> | ||

<td>[http://ac.els-cdn.com/S0003986101925226/1-s2.0-S0003986101925226-]</td> | <td>[http://ac.els-cdn.com/S0003986101925226/1-s2.0-S0003986101925226-]</td> | ||

| - | <td></td> | + | <td>-</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 1,246: | Line 1,186: | ||

<p align="justify"> | <p align="justify"> | ||

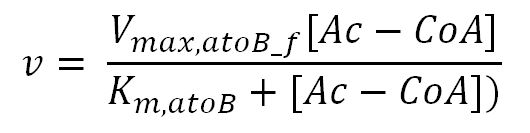

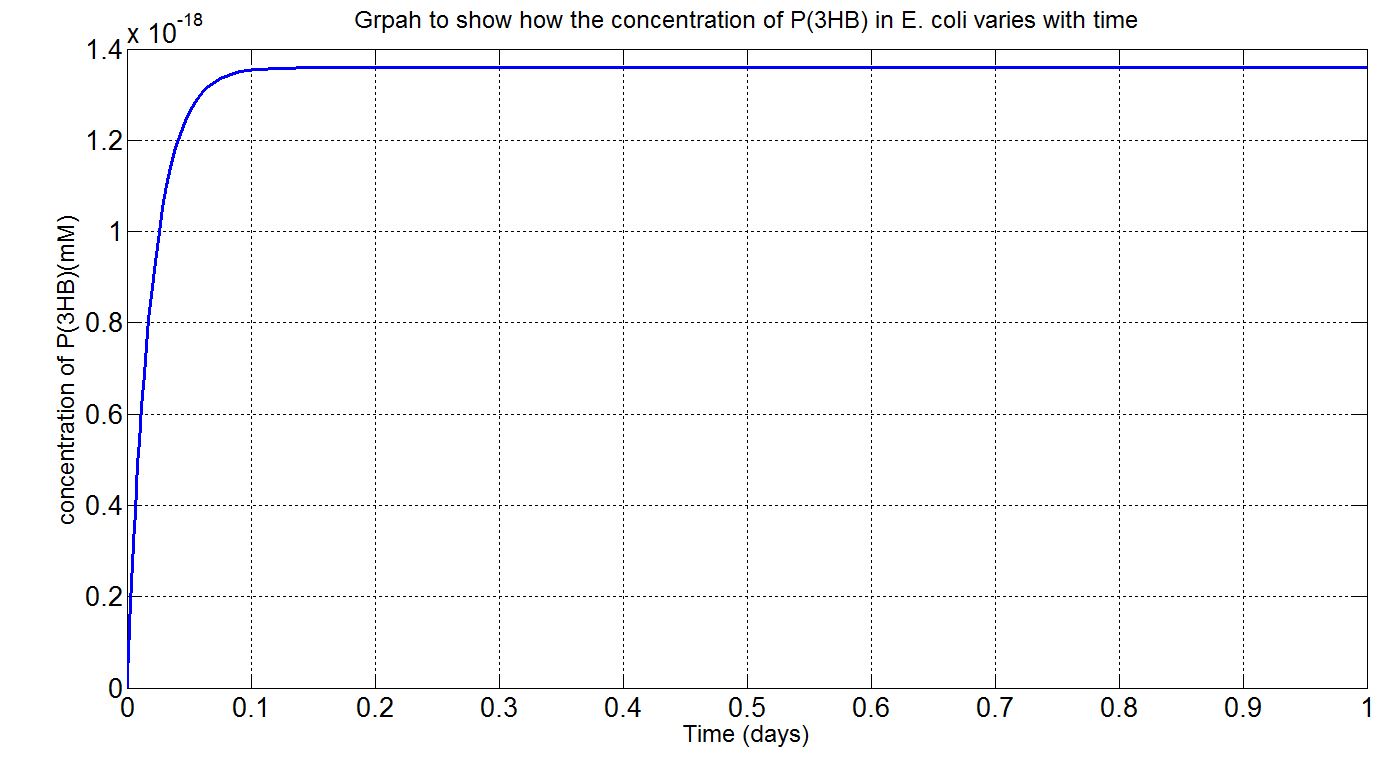

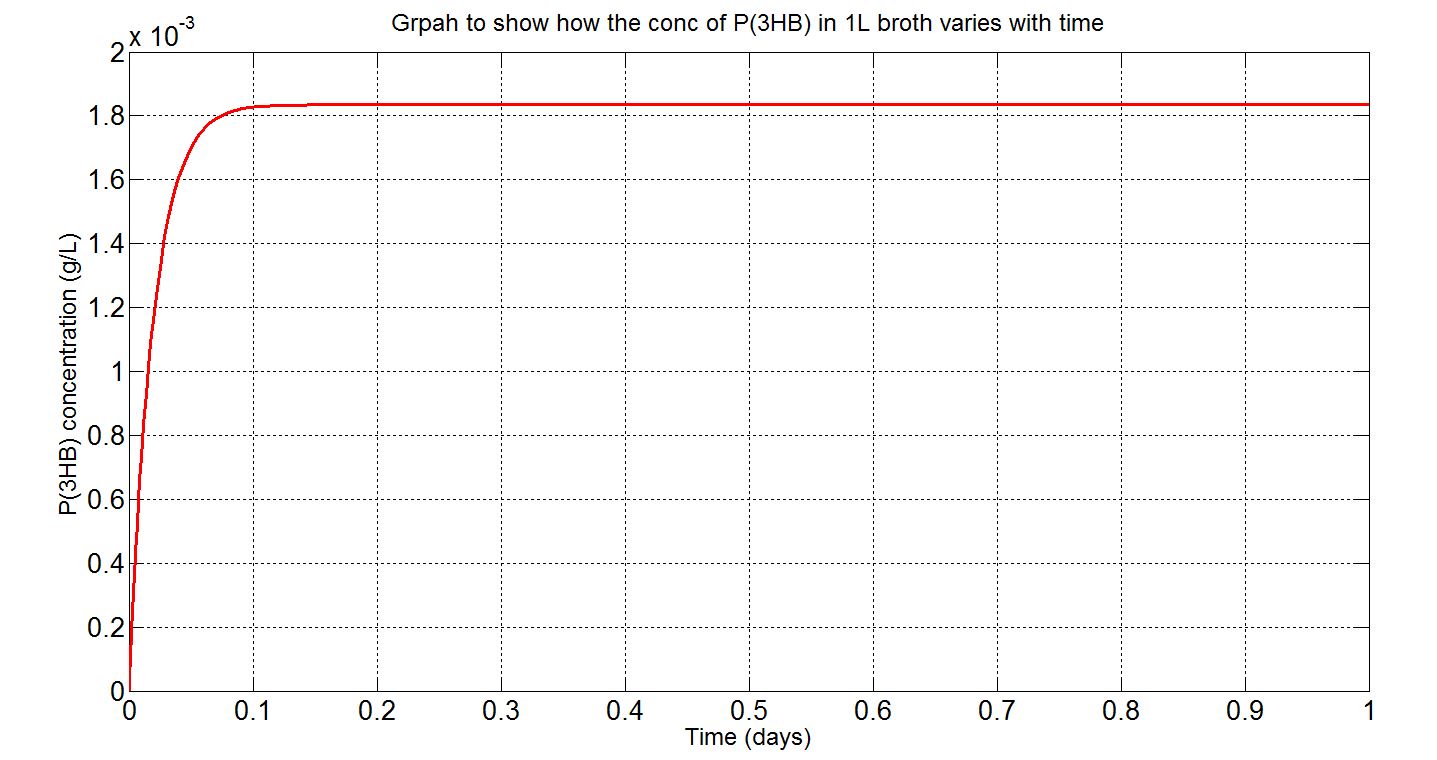

| - | Using the values presented in the tables above, the deterministic model was simulated to see how much P(3HB) could be formed inside the cell | + | Using the values presented in the tables above, the deterministic model was simulated to see how much P(3HB) could be formed inside the cell. However, with the single cell model, it would be difficult to reflect how much of the plastic could actually be formed on a macroscopic scale. Therefore, modifications to the simulation algorithm were needed to give scaled-up simulation results. |

</p> | </p> | ||

| Line 1,254: | Line 1,194: | ||

<p align="justify"> | <p align="justify"> | ||

| - | Here, three graphs are presented to show P(3HB)formation over time. The first two graphs are (i)single-cell model results, concentration in mM and (ii) single-cell model results, concentration in g/L. The first graph was the original graph produced from Simbiology as all concentrations were expressed in mM in the model. However, to gain a more intuitive sense of how much could be produced g/L was used. The third graph is the scaled-up simulation result. | + | Here, three graphs are presented to show P(3HB)formation over time. The first two graphs are (i)single-cell model results, concentration in mM and (ii) single-cell model results, concentration in g/L. The first graph was the original graph produced from Simbiology as all concentrations were expressed in mM in the model. However, to gain a more intuitive sense of how much could be produced g/L was used. The third graph is the scaled-up simulation result. |

</p> | </p> | ||

<p>'''(i) please see assumptions and explanations below'''</p> | <p>'''(i) please see assumptions and explanations below'''</p> | ||

| Line 1,370: | Line 1,310: | ||

<h4>P(3HB) synthesis model:Download</h4> | <h4>P(3HB) synthesis model:Download</h4> | ||

<p><a href="https://2013.igem.org/File:P3HB_synthesis_model.zip"><img src="https://static.igem.org/mediawiki/2011/8/8c/ICL_DownloadIcon.png" width="180px" /></a></p> | <p><a href="https://2013.igem.org/File:P3HB_synthesis_model.zip"><img src="https://static.igem.org/mediawiki/2011/8/8c/ICL_DownloadIcon.png" width="180px" /></a></p> | ||

| + | |||

| + | <h4>Additional script:Download</h4> | ||

| + | <p><a href="https://2013.igem.org/File:P3HB_additional_scripts.zip"><img src="https://static.igem.org/mediawiki/2011/8/8c/ICL_DownloadIcon.png" width="180px" /></a></p> | ||

| + | |||

| + | |||

</html> | </html> | ||

<html> | <html> | ||

| Line 1,395: | Line 1,340: | ||

<p>The initial concentrations of all metabolites and kinetic data are referenced in the paper.[http://digitalcommons.usu.edu/engineering_datasets/1/] The simulation of the metabolites is:</p> | <p>The initial concentrations of all metabolites and kinetic data are referenced in the paper.[http://digitalcommons.usu.edu/engineering_datasets/1/] The simulation of the metabolites is:</p> | ||

[[File:Metabolite.png]] | [[File:Metabolite.png]] | ||

| - | <p> | + | <p> Table of initial and steady-state concentrations of the metabolites:</p> |

<table border="2" bgcolor="#efefef"> | <table border="2" bgcolor="#efefef"> | ||

<tr> | <tr> | ||

| Line 1,412: | Line 1,357: | ||

<td>200</td> | <td>200</td> | ||

| - | <td> | + | <td>250</td> |

<td>uM</td> | <td>uM</td> | ||

<td>[http://digitalcommons.usu.edu/engineering_datasets/1/]</td> | <td>[http://digitalcommons.usu.edu/engineering_datasets/1/]</td> | ||

| Line 1,430: | Line 1,375: | ||

<th>Acetyl-coA</th> | <th>Acetyl-coA</th> | ||

| - | <td> | + | <td>1000</td> |

<td>100</td> | <td>100</td> | ||

<td>uM</td> | <td>uM</td> | ||

| Line 1,440: | Line 1,385: | ||

<td>250</td> | <td>250</td> | ||

| - | <td> | + | <td>5500</td> |

<td>uM</td> | <td>uM</td> | ||

<td>[http://digitalcommons.usu.edu/engineering_datasets/1/]</td> | <td>[http://digitalcommons.usu.edu/engineering_datasets/1/]</td> | ||

| Line 1,450: | Line 1,395: | ||

<td>200</td> | <td>200</td> | ||

| - | <td> | + | <td>380</td> |

<td>uM</td> | <td>uM</td> | ||

<td>[http://digitalcommons.usu.edu/engineering_datasets/1/]</td> | <td>[http://digitalcommons.usu.edu/engineering_datasets/1/]</td> | ||

| Line 1,469: | Line 1,414: | ||

</table> | </table> | ||

| + | <p align="justify"> | ||

| + | |||

| + | <p align="justify"> | ||

| + | It should also be noted that acetate, acetoacetate and acetoacetyl-CoA cannot be predicted by the metabolic model. Therefore, their initial concentrations are rough estimates (value similar to other metabolites) such that a reasonable P(3HB) output can be produced.</p> | ||

<html> | <html> | ||

</div> | </div> | ||

| Line 1,490: | Line 1,439: | ||

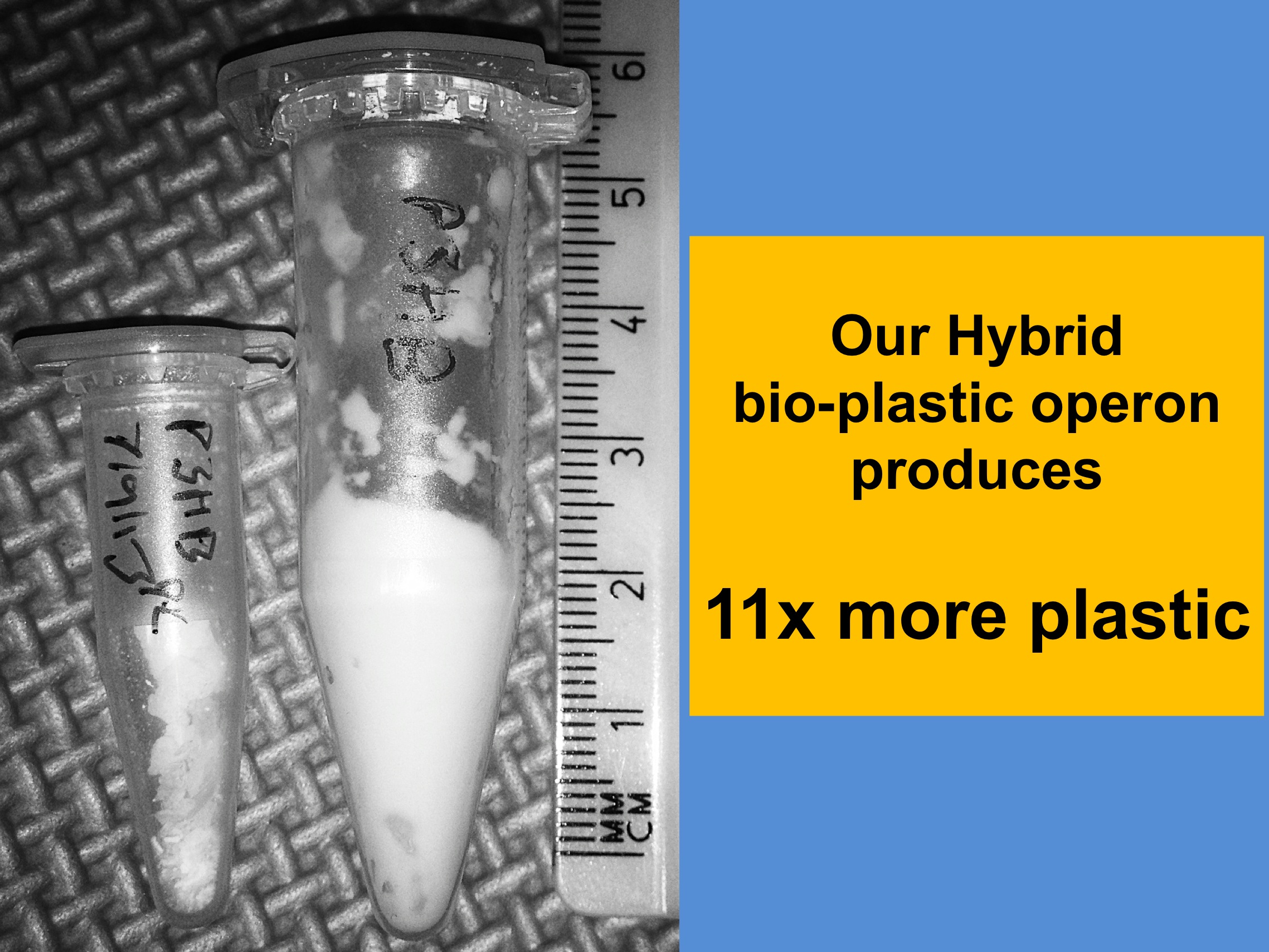

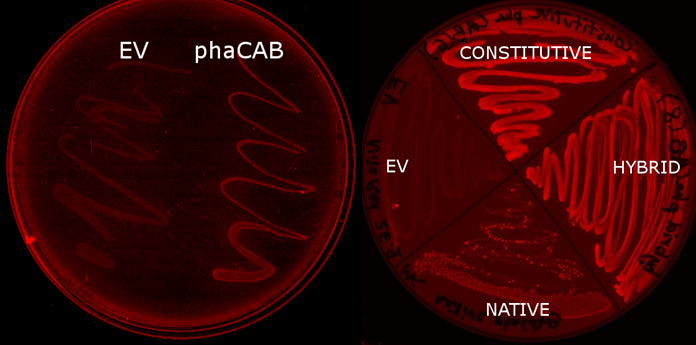

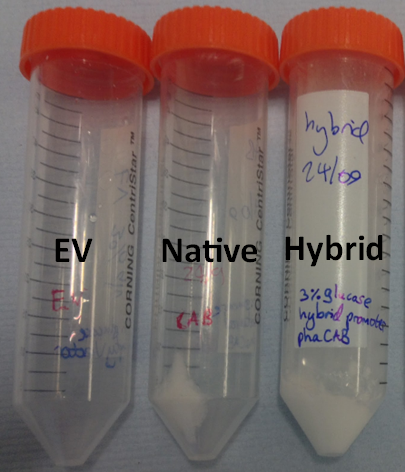

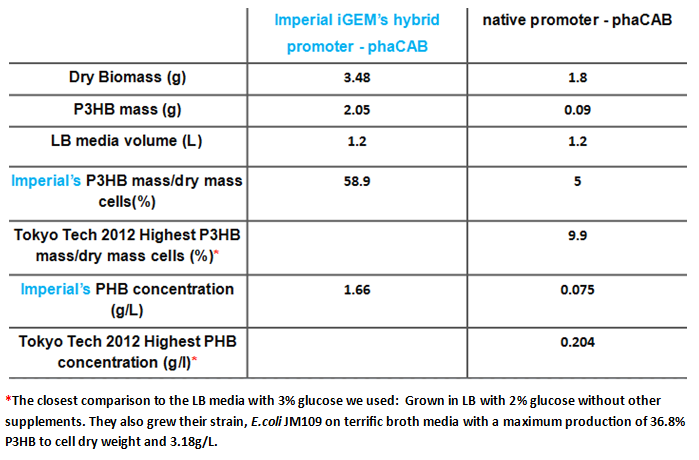

<b>We made two new improved constructs by modifying the native operon:</b> | <b>We made two new improved constructs by modifying the native operon:</b> | ||

| - | + | The modellers in the drylab predicted that an increased level of pha B enzyme will increase the amount of PHB produced and therefore we decided to change the native <i>Ralstonia eutropha</i> promoter and RBS to a strong constitutive <i>E.coli</i> promoter (J23104) and RBS (0034) in front of the operon. We have succeeded with the swap and built the new biobrick [http://parts.igem.org/Part:BBa_K1149052 BBa_K1149052] which we refer to as constitutive phaCAB. In parallel, we have also assembled a different configuration of transcription initiation region: the "hybrid". Surprisingly, our results show that our "hybrid" phaCAB construct [http://parts.igem.org/Part:BBa_K1149051 BBa_K1149051] significantly increased bioplastic production compared to native pha CAB. Please read on to discover more. </p> | |

| - | We tested the promoter and RBS | + | We tested the promoter and RBS by cloning them in front of amilCP blue chromoprotein gene ([http://parts.igem.org/Part:BBa_K1149020 BBa_K1149020]). As you can see from the plate below, this expresses a bright blue protein, which became an intrinsic part of our [https://2013.igem.org/Team:Imperial_College/Communication_work# BioNouveau] palette. |

<br> | <br> | ||

https://static.igem.org/mediawiki/igem.org/f/fb/PlasticityBluePlate.JPG | https://static.igem.org/mediawiki/igem.org/f/fb/PlasticityBluePlate.JPG | ||

| Line 1,520: | Line 1,469: | ||

<div id="CollapsiblePanel1" class="CollapsiblePanel"> | <div id="CollapsiblePanel1" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Our chassis (MG1655) survives in mixed waste </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

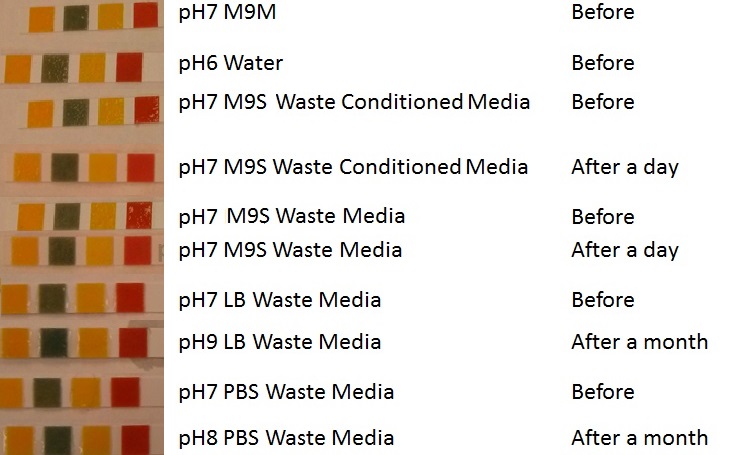

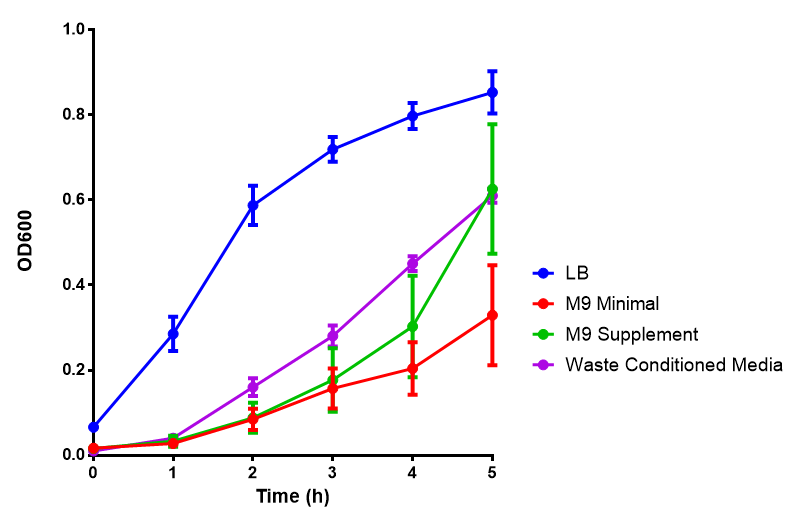

| Line 1,526: | Line 1,475: | ||

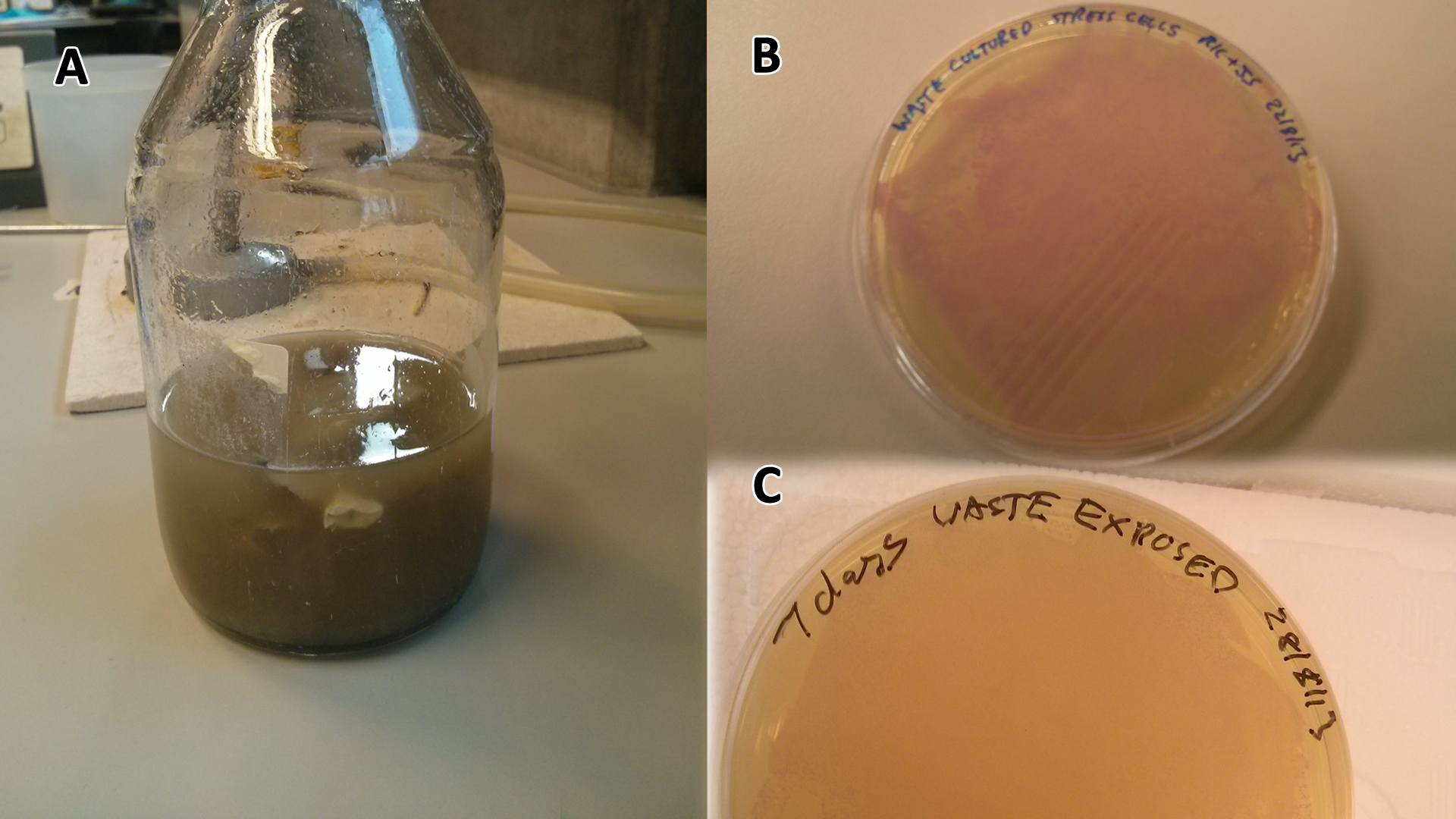

<b>These assays were designed to test whether our chassis, <i>E.coli</i> (MG1655) could grow directly with waste over a long period of time. </b> | <b>These assays were designed to test whether our chassis, <i>E.coli</i> (MG1655) could grow directly with waste over a long period of time. </b> | ||

| - | < | + | <h4>Waste media</h4> |

{| class="wikitable" style="margin: 1em auto 1em auto;" | {| class="wikitable" style="margin: 1em auto 1em auto;" | ||

| Line 1,536: | Line 1,485: | ||

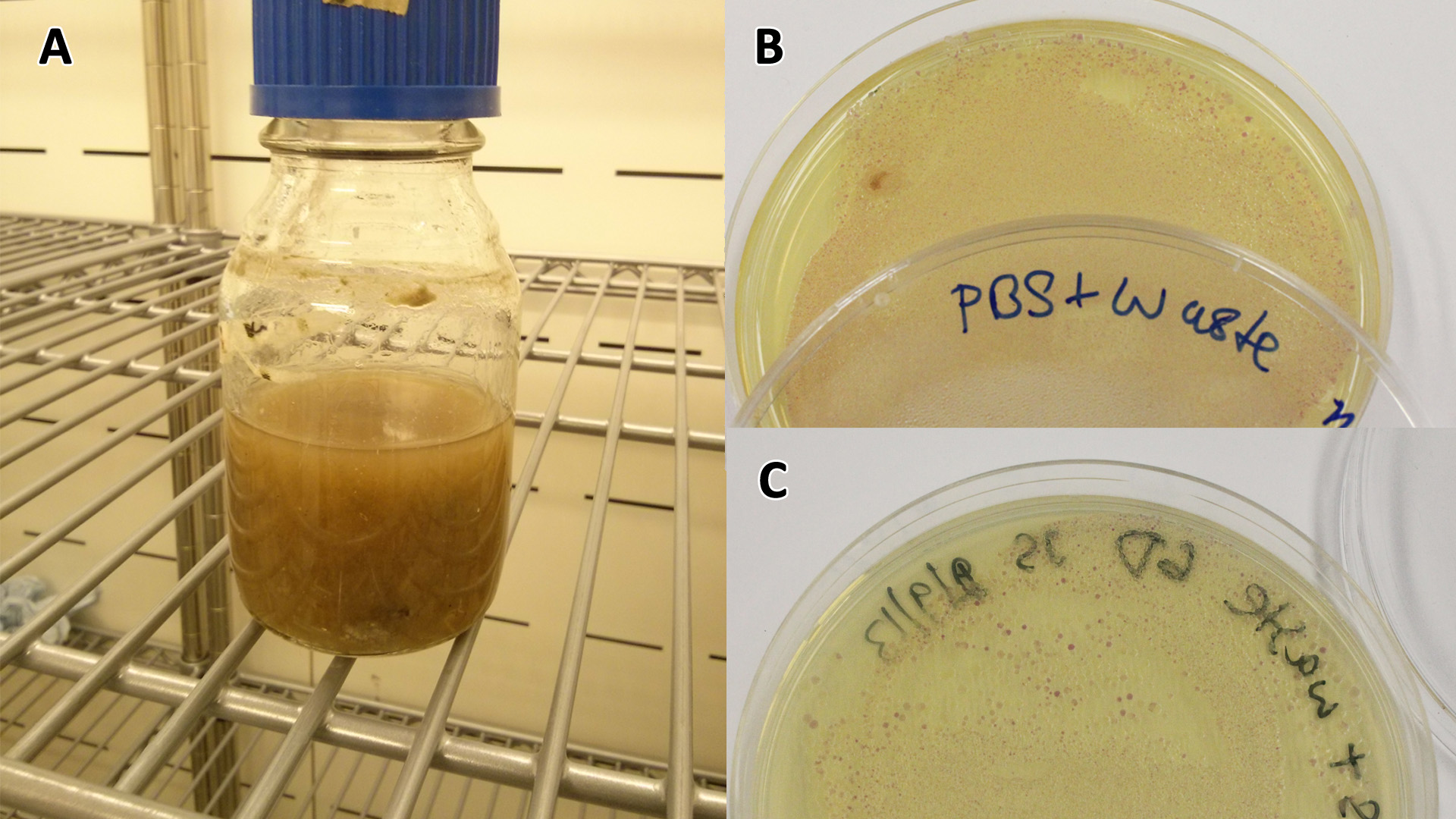

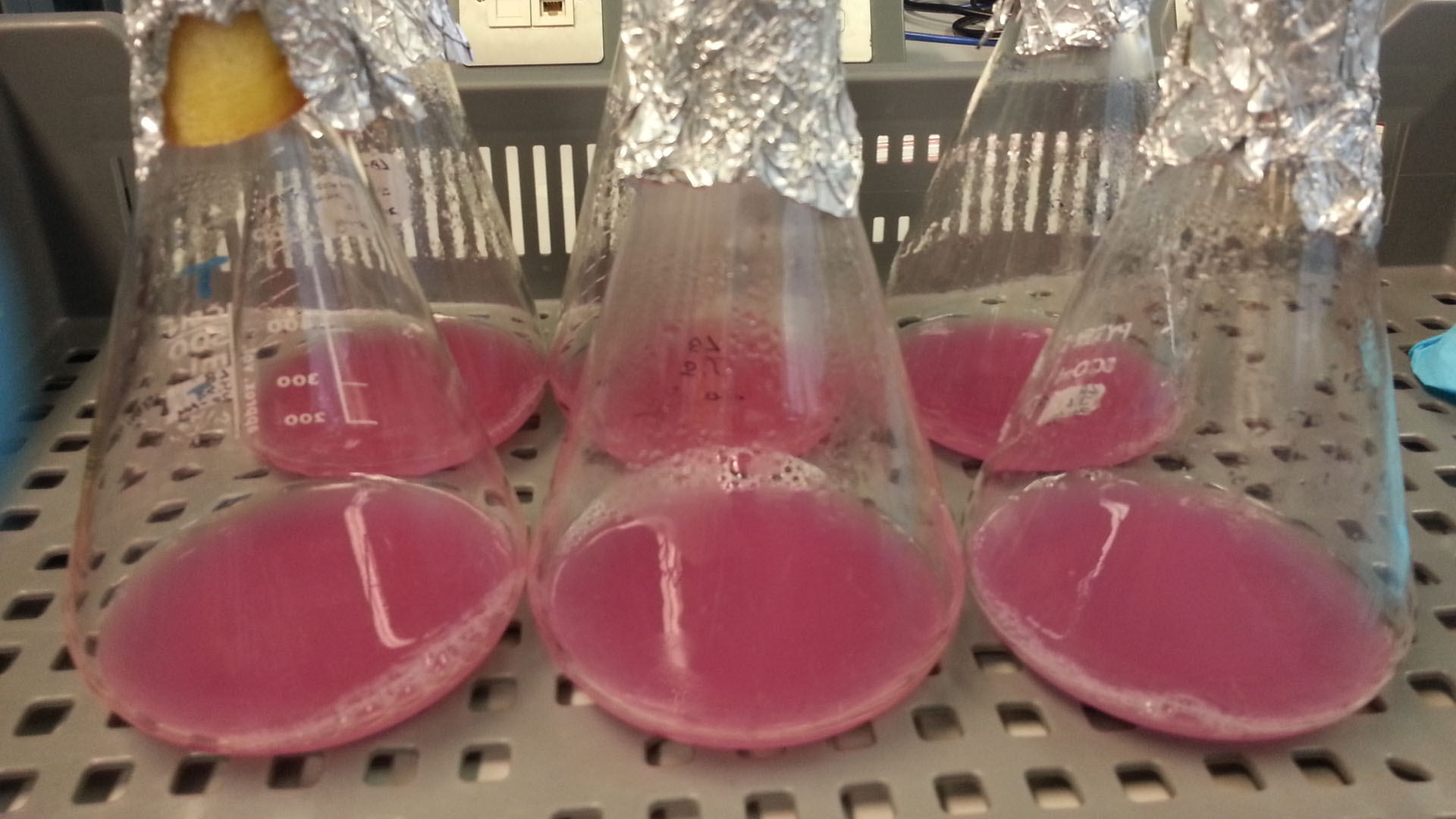

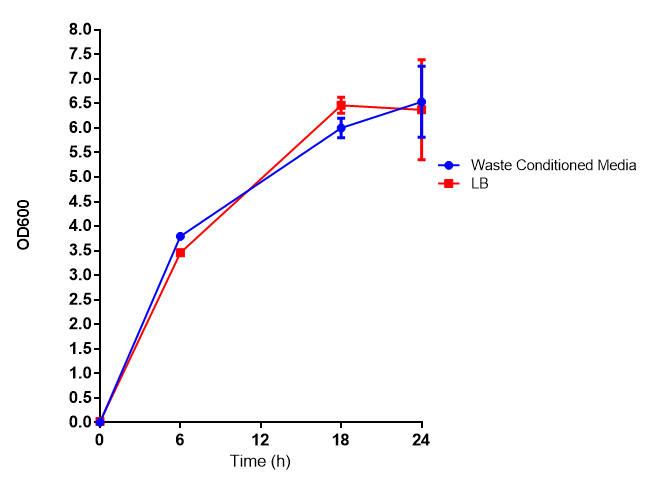

| - | < | + | <h4>Waste conditioned media</h4> |

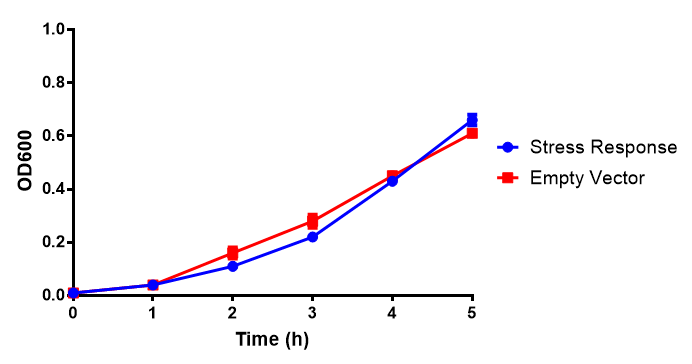

These assays were designed to test whether our chassis, <i>E.coli</i> MG1655 strain could grow with waste conditioned media (WCM) over a period of 24-48 hours. Waste conditioned media is a filter sterilised version of the waste media and was designed for several reasons; Firstly we were unsure whether mixed waste would be toxic to <i>E.coli</i> and hence a less concentrated version may be more suitable and secondly large chunks of waste would prevent accurate OD600 measurements and therefore we decided to filter out the largest chunks. | These assays were designed to test whether our chassis, <i>E.coli</i> MG1655 strain could grow with waste conditioned media (WCM) over a period of 24-48 hours. Waste conditioned media is a filter sterilised version of the waste media and was designed for several reasons; Firstly we were unsure whether mixed waste would be toxic to <i>E.coli</i> and hence a less concentrated version may be more suitable and secondly large chunks of waste would prevent accurate OD600 measurements and therefore we decided to filter out the largest chunks. | ||

| Line 1,560: | Line 1,509: | ||

</div> | </div> | ||

<div id="CollapsiblePanel2" class="CollapsiblePanel"> | <div id="CollapsiblePanel2" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Mixed waste degradation: Polyurethane (PUR) </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

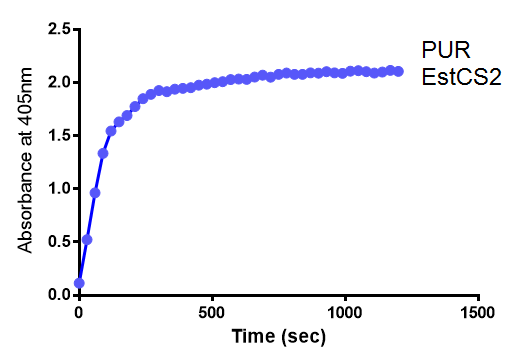

| - | < | + | <h4> PUR Esterase enzyme activity </h4> |

<h4>Cell lysate assay</h4> | <h4>Cell lysate assay</h4> | ||

| Line 1,609: | Line 1,558: | ||

</div> | </div> | ||

<div id="CollapsiblePanel3" class="CollapsiblePanel"> | <div id="CollapsiblePanel3" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Mixed waste degradation: Toxicity </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

| - | < | + | <h4>Ethylene glycol </h4> |

[[File:EG_growth.png|thumbnail|center|600px|<b> Ethylene glycol in LB with Stress Response cells.</b> MG1655 were grown in ethylene glycol, a byproduct of polyurethane degradation. Cells were grown in 0mM, 100mM or 200mM Ethylene Glycol. At 37°C, the concentrations of ethylene glycol used do not affect growth, however at 30°C, the increasing concentration results in halved growth. A two-tailed t-test addressing the null hypothesis, temperature does not affect growth with ethylene glycol shows that the null hypothesis must be rejected as p = 0.001. Data points show final time point after 6h growth for each concentration. Growth was at 37°C and 30°C with shaking over 6h. Error bars are SEM, n=4. Figure made by Imperial College London 2013 iGEM.]] | [[File:EG_growth.png|thumbnail|center|600px|<b> Ethylene glycol in LB with Stress Response cells.</b> MG1655 were grown in ethylene glycol, a byproduct of polyurethane degradation. Cells were grown in 0mM, 100mM or 200mM Ethylene Glycol. At 37°C, the concentrations of ethylene glycol used do not affect growth, however at 30°C, the increasing concentration results in halved growth. A two-tailed t-test addressing the null hypothesis, temperature does not affect growth with ethylene glycol shows that the null hypothesis must be rejected as p = 0.001. Data points show final time point after 6h growth for each concentration. Growth was at 37°C and 30°C with shaking over 6h. Error bars are SEM, n=4. Figure made by Imperial College London 2013 iGEM.]] | ||

| Line 1,624: | Line 1,573: | ||

</div> | </div> | ||

<div id="CollapsiblePanel4" class="CollapsiblePanel"> | <div id="CollapsiblePanel4" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Bioplastic production </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

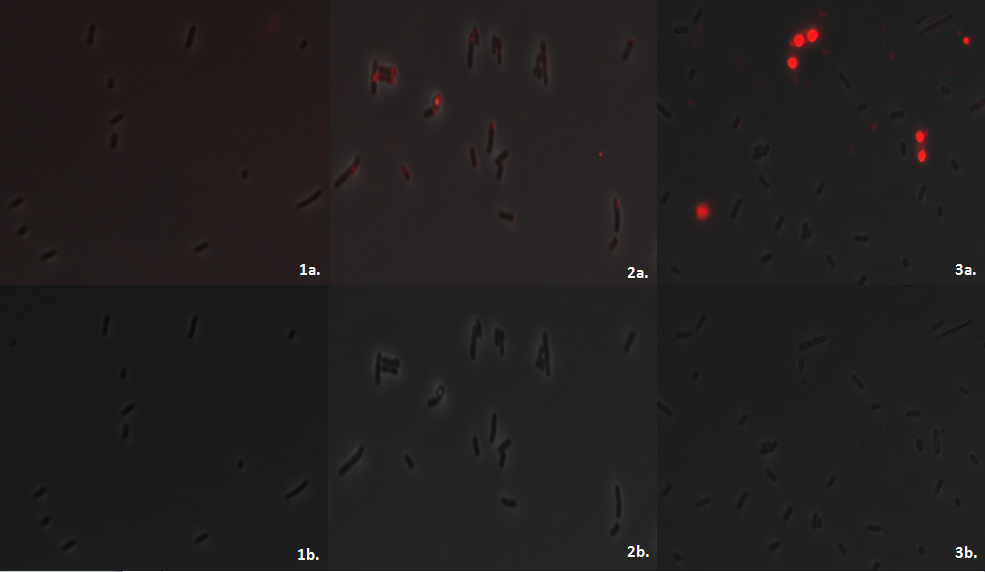

| Line 1,662: | Line 1,611: | ||

</div> | </div> | ||

<div id="CollapsiblePanel5" class="CollapsiblePanel"> | <div id="CollapsiblePanel5" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Increasing Bioplastic Production </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

| Line 1,685: | Line 1,634: | ||

</div> | </div> | ||

<div id="CollapsiblePanel6" class="CollapsiblePanel"> | <div id="CollapsiblePanel6" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Bioplastic from mixed waste </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

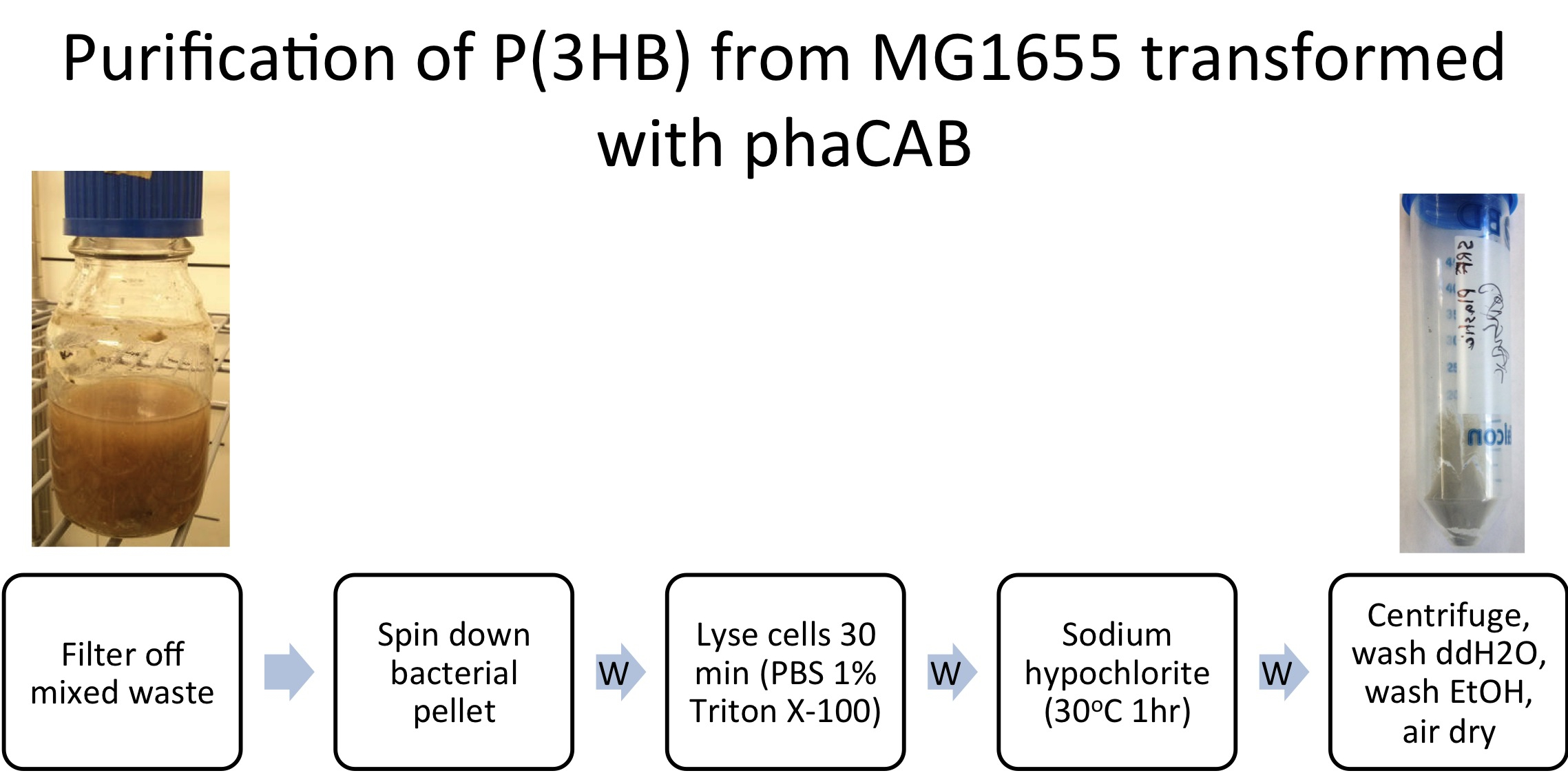

| Line 1,695: | Line 1,644: | ||

[[File:Purification_of_P(3HB).jpg|thumbnail|center|600px|<b>P(3HB) purification:</b> The diagram summaries the process of P(3HB) purification from E. coli (MG1655) transformed with native phaCAB (BBa_K934001)]] | [[File:Purification_of_P(3HB).jpg|thumbnail|center|600px|<b>P(3HB) purification:</b> The diagram summaries the process of P(3HB) purification from E. coli (MG1655) transformed with native phaCAB (BBa_K934001)]] | ||

| - | < | + | <p class="clear">See [https://www.youtube.com/watch?v=4msf6EMNIrY here] a video of the process.</p> |

| + | <h2>3HB Assay: Confirming production of 3HB</h2> | ||

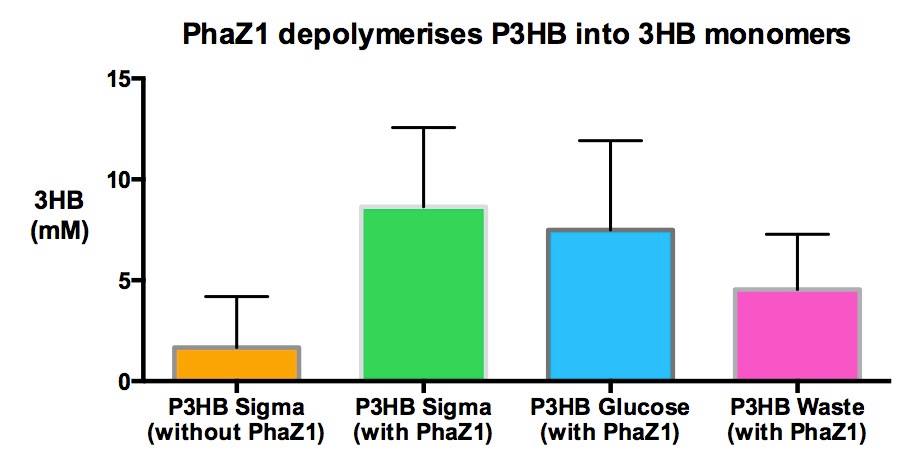

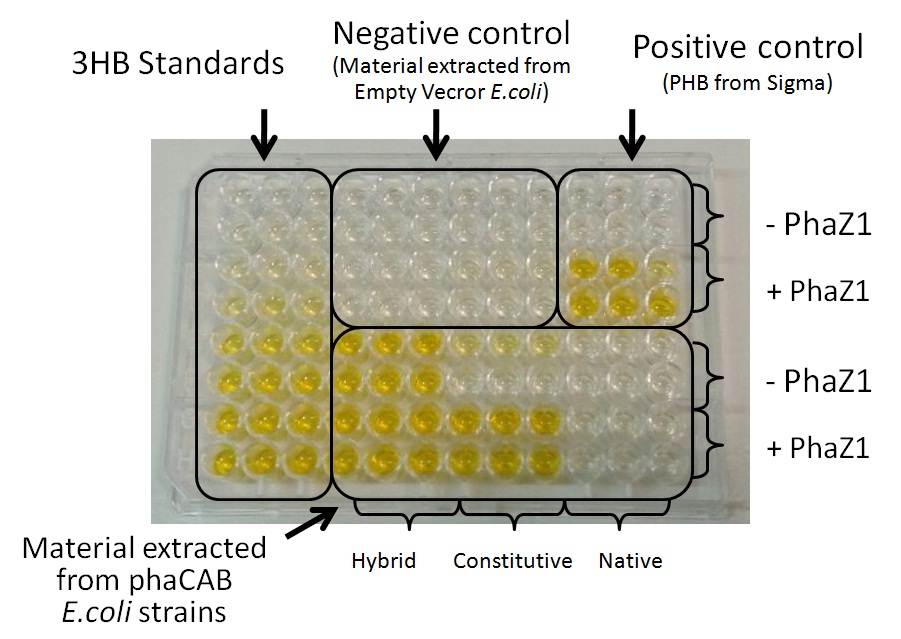

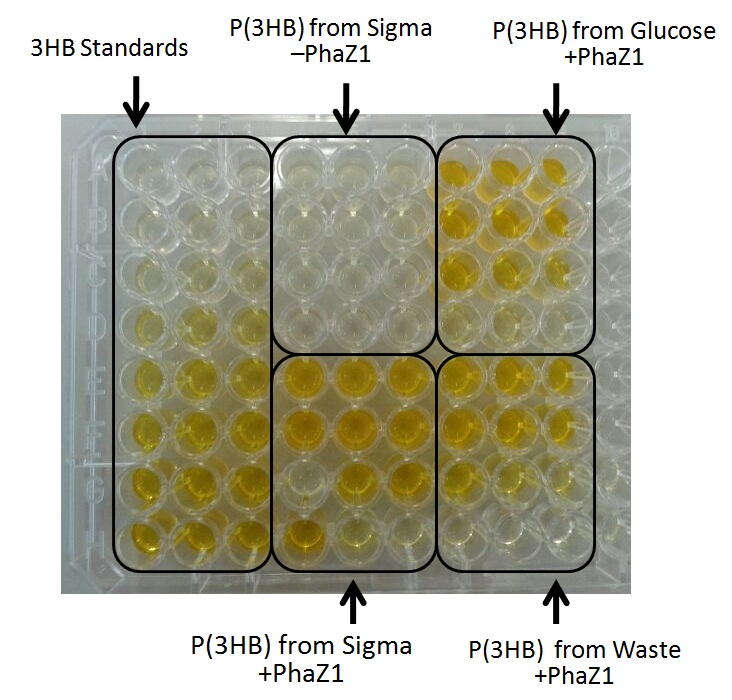

| + | We have adapted a medical kit for 3HB detection for chemically analysing our samples. This provided a simple but accurate mean to measure the 3HB liberated from the polymer after phaZ1 depolymerase enzyme treatment. The monomer 3HB indicated the presence of P(3HB) in the material we purified from cells grown on waste as a sole carbon source. Please see the protocol [https://2013.igem.org/Team:Imperial_College/Protocols#3HB_assay here] and our data and calculations [https://2013.igem.org/Team:Imperial_College/3HB_assay here]. | ||

| + | <br> | ||

{| class="wikitable" style="margin: 1em auto 1em auto;" | {| class="wikitable" style="margin: 1em auto 1em auto;" | ||

| - | |[[File: | + | |[[File:3HB_assay_from_PHB_new.jpg|thumbnail|left|600px| <b>The chemical analysis of the produced bioplastic. The samples break break down to 3HB monomers after treatment with our PhaZ1 enzyme (BBa_K1149010). We synthesised P(3HB) using our improved Biobrick part (hybrid promoter phaCAB, BBa_K1149051). Our engineered bioplastic producing <i>E.coli</i> synthesised P(3HB) directly from waste. (Imperial iGEM data [https://2013.igem.org/Team:Imperial_College/3HB_assay here].)</b>]] |

|} | |} | ||

| - | + | [[File:Imperial_P3HB_from_waste.jpg|thumbnail|centre|600px|<font size="2.7"><b>The bioplastic produced by our bacteria contains PHB and can be broken down into monomers by PhaZ1 enzyme (expressed by our bacteria)Imperial iGEM data.</b>]] | |

| + | <br> | ||

| + | We repeated the previously described experiment with <i>E.coli</i> cells containing all three P(3HB) production operons, grown on waste media. We also also tested the material left after the extraction protocol from cells containing the Empty vector only, grown on waste media. The yellow colour indicates presence of 3HB. | ||

| + | [[File:Full_annotated_diagram.jpg|thumbnail|centre|600px|<font size="2.7"><b>Production of PHB from waste confirmed. Imperial iGEM data.</b>]] | ||

| - | |||

<html> | <html> | ||

| Line 1,709: | Line 1,663: | ||

</div> | </div> | ||

<div id="CollapsiblePanel7" class="CollapsiblePanel"> | <div id="CollapsiblePanel7" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Extras </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

| Line 1,727: | Line 1,681: | ||

</div> | </div> | ||

<div id="CollapsiblePanel8" class="CollapsiblePanel"> | <div id="CollapsiblePanel8" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>Protocols </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

<h4>Waste Conditioned Media (WCM)</h4> | <h4>Waste Conditioned Media (WCM)</h4> | ||

| Line 1,733: | Line 1,687: | ||

SRF refers to the refuse from recycling facilities that has no value currently and is incinerated to produce power at a cost to the recycling facility, it is composed of 30% plastics while the rest is cellulosic waste</p> | SRF refers to the refuse from recycling facilities that has no value currently and is incinerated to produce power at a cost to the recycling facility, it is composed of 30% plastics while the rest is cellulosic waste</p> | ||

| + | |||

| + | |||

| + | <p class="clear">See here how we make up waste conditioned media and purify plastic from it.</p> | ||

| + | <iframe width="840" height="630" src="//www.youtube-nocookie.com/embed/1oXt_EfqmLU?rel=0" frameborder="0" allowfullscreen></iframe> | ||

| + | |||

<h4>Waste Growth Assay</h4> | <h4>Waste Growth Assay</h4> | ||

| Line 1,746: | Line 1,705: | ||

</div> | </div> | ||

<div id="CollapsiblePanel9" class="CollapsiblePanel"> | <div id="CollapsiblePanel9" class="CollapsiblePanel"> | ||

| - | <div class="CollapsiblePanelTab" tabindex="0">< | + | <div class="CollapsiblePanelTab" tabindex="0"><h4>MSDS </html><font size="1">▼</font size="1"><html></h4></div> |

<div class="CollapsiblePanelContent"> | <div class="CollapsiblePanelContent"> | ||

</html> | </html> | ||

| Line 1,773: | Line 1,732: | ||

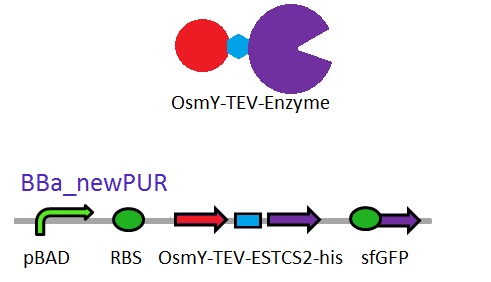

<b>We are changing the pelB secretion tag to OsmY-fusion partner for better secretion</b> | <b>We are changing the pelB secretion tag to OsmY-fusion partner for better secretion</b> | ||

| - | <p>As seen in the [https://2013.igem.org/Team:Imperial_College/Western_Blots Western Blot] results, some of the enzymes designed for secretion were not secreted. These proteins may have been stuck in the periplasmic space. Thus we are optimising enzyme secretion by building a new construct with OsmY [http://parts.igem.org/Part:BBa_K892008 BBa_K892008] fusion for secretion. OsmY is naturally secreted from E.coli and will carry our PUR esterase enzyme with. Once in the culture medium, we think that the enzyme is going to be functional in the fusion form but we included a TEV site in between the domains that can be cleaved by TEV protease if needed.</p> | + | <p>As seen in the [https://2013.igem.org/Team:Imperial_College/Western_Blots Western Blot] results, some of the enzymes designed for secretion were not secreted. These proteins may have been stuck in the periplasmic space. Thus we are optimising enzyme secretion by building a new construct with OsmY [http://parts.igem.org/Part:BBa_K892008 BBa_K892008] fusion for secretion. OsmY is naturally secreted from <i>E.coli</i> and will carry our PUR esterase enzyme with. Once in the culture medium, we think that the enzyme is going to be functional in the fusion form but we included a TEV site in between the domains that can be cleaved by TEV protease if needed.</p> |

[[File:FuturePURbrick.jpg|400px|center]] | [[File:FuturePURbrick.jpg|400px|center]] | ||

| Line 1,781: | Line 1,740: | ||

This construct will be a substitute for [http://parts.igem.org/Part:BBa_K1149002 BBa_K1149002] which is the PUR esterase EstCS2 with the pelB seretion tag. | This construct will be a substitute for [http://parts.igem.org/Part:BBa_K1149002 BBa_K1149002] which is the PUR esterase EstCS2 with the pelB seretion tag. | ||

| - | <b>We will | + | UPDATE 28-10-13: |

| + | |||

| + | Whilst further optimisation is required a western blot analysis of our new construct OsmY-ESTC2 indicated that our enzyme maybe secreting into the supernatant. | ||

| + | |||

| + | |||

| + | <b>We will test our Hybrid phaCAB within a bioreactor setup</b> | ||

| - | + | We will inoculate a 15L bioreactor at Imperial College London to perform a pilot scale test of our plastic producing system. | |

<html></p> | <html></p> | ||

Latest revision as of 03:48, 29 October 2013

Module 1: Resource-full Waste

Non-recyclable waste is sourced from a recycling centre, placed in a bioreactor with our M.A.P.L.E system which degrades the waste and synthesises the bioplastic P(3HB). Click the tabs to find out more

Overview

Specifications

Design

Modelling

Assembly

Testing & results

Future work

Waste from recovery facilities is a mixture of plastics and cellulosic rich biomass such as fibres and wood. The Resource-full waste module utilises the large variety of materials organisms can naturally degrade to recycle the waste and to provide food for the production of the bioplastic poly-3-hydroxybutyrate, P(3HB).

Separating polyurethane and selling its breakdown products

Certain enzymes have the ability to degrade plastics as a result of their evolutionary history, dealing with tough and highly variable substrates such as lignin. Various enzymes have been biobricked to deal with most of the major petrochemical plastics, except for polyurethane. Polyurethane is one of the plastic constituents of this mixed waste. We have designed biobricks containing naturally occurring polyurethane esterases (also known as PUR esterases) to break polyurethane down into its constituent chemicals of ethylene glycol and poly(isocyanate). These valuable chemicals will be separated using specialised filters and sold back to industry.

Using the residual material as a substrate for P(3HB) production

The remaining organic portion of the mixed waste is used as a carbon source for P(3HB) production. P(3HB) is produced by organisms containing the pha CAB operon, originally found in soil bacteria such as Ralstonia eutropha. The operon contains three genes which are members of the pathway required to make P(3HB). P(3HB) is used as a storage molecule in the organisms which produce it. They do this when nutrients are limiting but when there is a plentiful carbon source.

P(3HB) is produced commercially by several companies. One of the crucial factors in whether production is economical or not is the efficiency of bioplastic production. We have hugely increased the efficiency of P(3HB) production; an important step in making our system feasible.

To scale up the production of P(3HB), our system would require large amounts of purified sugars. We would, therefore, hydrolyse the long polysaccharide components to release the sugars. This is a current industrial pre-treatment technique to allow the fermentation of ligno-cellulosic biomass.

References:

- Harding KG, Dennis JS, von Blottnitz H, Harrison STL. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically-based poly-beta-hydroxybutyric acid using life cycle analysis. J Biotechnol 2007 MAY 31;130(1):57-66.

- Kim S, Dale BE. Energy and Greenhouse Gas Profiles of Polyhydroxybutyrates Derived from Corn Grain: A Life Cycle Perspective. Environ Sci Technol 2008 OCT 15;42(20):7690-7695.

- Kendall A. A life cycle assessment of biopolymer production from material recovery facility residuals. Resources, Conservation and Recycling 61 (2012) 69– 74 conomou A. Following the leader: bacterial protein export through the Sec pathway. Trends in microbiology 1999;7(8) 315-320.

- Chul-Hyung Kang, Ki-Hoon Oh, Mi-Hwa Lee, Tae-Kwang Oh, Bong Hee Kim, Jung- Hoon Yoon. A novel family VII esterase with industrial potential from compost metagenomic libraryMicrobial Cell Factories 2011, 10:41 doi:10.1186/1475-2859-10-41

- Da Almeida, Alejandra. Effect of the granule associated protein phasin (PhaP) on cell growth and poly(3-hydroxybutyrate) (PHB) accumulation from glycerol in bioreactor cultures of recombinant E. coli. Volume 131, Issue 2, Supplement, September 2007, Pages S167.

Specification

1. Our bacteria should survive and grow in mixed waste

In order for the bacteria to produce bioplastic from the mixed waste they first need to be able to use it as a carbon source

2. Our bacteria should secrete a functional polyurethane esterase

To recover the resources from polyurethane in the mixed waste, the enzymes should secrete in an active form.

3. Our bacteria should be able to tolerate mixed waste degradation products, such as ethylene glycol

The products of polyurethane degradation are toxic and so any bacteria growing with them must be able to survive to a concentration which will allow economical production of ethylene glycol. We have chosen a strain of E.coli-MG1655, which is resistant to ethylene glycol toxicity.

4. Our bacteria should produce P(3HB)

5. Our bacteria should produce P(3HB) from the mixed waste

PUR Degradation: Pathway ▼

Lignin degrading microbial enzymes are capable of degrading plastics. Some previous iGEM teams have exploited this ability. We have built on their work and extended the plastic degradation capabilities of the synthetic biology community by improving polyurethane (PUR) degradation, as this has not been successfully achieved before. We have identified 5 PUR-esterase enzymes from the literature that are capable of catalyzing the below reaction.

We have synthesised all of the genes in the below table and are testing them for expression in E.coli, secretion, activity and PUR degradation capabilities. Our ultimate design is to be able to control the relative levels of different enzymes in a waste-degrading bio-reactor, in order to adjust it to the composition of waste. We have, therefore, designed the expression constructs accordingly. Our models predict the degradation rate of polyurethane at the bioreactor scale. .

PUR Degradation: BioBrick Designs ▼

| enzyme | source organism | biobrick | reference |

|---|---|---|---|

| EstCS2 | uncultured unknown bacterium (GU256649.1) | BBa_K1149002 | Kang et.al 2011 |

| pueA | Pseudomonas chlororaphis | BBa_K1149003 | Stern et al., 2000 |

| pueB | Pseudomonas chlororaphis | BBa_K1149004 | Howard et al., 2001 |

| pudA | Comamonas acidovorans | BBa_K1149005 | Allen et al. 1999 |

| pulA | Pseudomonas fluorescens | BBa_K1149006 | Vega et al., 1999 |

Secretion Strategy:

E.coli is commonly used as a chassis in innovative iGEM projects that aim to prove a concept and make the case for a novel function in a biologically engineered machine. In our case, we aim to degrade and synthesise plastic and the degradation part of our system needs to be extracellular. There are many strategies for secretion. You can read about these on our Secretion Guide page and find the corresponding biobricks and projects. If you are currently in the process of designing a Genetically Engineered Machine in E.coli, this page provides a good starting point to look for information.

We chose the pelB secretion tag as it has been demonstrated to work in many cases, sometimes with very high transport efficiency (1)(2). pelB has been used in iGEM projects for many years and is part of 50+ constructs. The UC-Davis team last year used it to secrete LC-Cutinase, a PET plastic degrading enzyme [http://parts.igem.org/Part:BBa_K936013 (BBa_K936013)] successfully, which is somewhat similar to our plastic-degrading enzymes.

Safety:

We considered the safety aspects of using the PudA enzyme, since its sequences were originally from a Risk Group 2 (RG2) organism. We submitted our safety information to iGEM for review. Safety forms were approved on October 2nd, 2013 by the iGEM Safety Committee. We did not use the organism only the part itself and the final sequences were codon optimised for expression in E. coli, which included the elimination of the forbidden restriction sites.

References

- Thanassi DG, Hultgren SJ. Multiple pathways allow protein secretion across the bacterial outer membrane. Current opinion in cell biology 2000;12(4) 420-430.

- Sletta H, Tondervik A, Hakvag S, Aune TEV, Nedal A, Aune R, et al. The presence of N-terminal secretion signal sequences leads to strong stimulation of the total expression levels of three tested medically important proteins during high-cell-density cultivations of E.coli. Applied and Environmental Microbiology 2007;73(3) 906-912.

Bioplastic Synthesis: Pathway ▼

Poly-3-hydroxybutyrate P(3HB) is a polyester which is naturally produced inside bacteria such as Ralstonia eutropha, where it accumulates as granules inside the cell. In its native bacteria it is produced as an energy store (1).It's properties as a plastic has gained it the attention of researchers and industrialists. In our system, the bacteria will take up organic molecules from waste and use them for P(3HB) production.

We have made P(3HB) in E.coli, transferring three genes naturally found in Ralstonia eutropha into E.coli MG1655. These encode the three enzymes necessary for P(3HB) production; polyhydroxyalkanoate synthase(phaC), 3-ketothiolase(phaA) and acetoacetyl coenzyme A reductase(phaB). These are encoded by the pha CAB operon. We have altered the expression of these three genes to maximise the production of P(3HB) as high yields are required for it to be economically viable.

3-ketothiolase:

Acetoacetyl coenzyme A reductase:

Polyhydroxyalkanoate synthase:

Bioplastic Synthesis: Biobrick Designs ▼

We used the pha CAB biobrick [http://parts.igem.org/Part:BBa_K934001 BBa_K934001] to produce P(3HB) which contains the native operon of Ralstonia eutropha. Inthe future we would like to see our system implemented at an industrial scale. This requires high yields to be economically viable. We created P(3HB) synthesis models to inform our experimental attempts to increase P(3HB) yield. We were especially interested to find out if up or down-regulation of any of the enzymes involved in the biosynthetic pathway could increase yields. To analyse this, we needed to know the reactions in the metabolic pathway and also the relative parameters of the enzymes and their dynamic relationships in order to identify bottlenecks in the flux of metabolites. The results from the metabolic model suggest that the amount of pha B is especially critical and increasing its level should give us more P(3HB). (Please see our modelling section for details.) To do this, we designed constructs with stronger promoters to up-regulate the expression of the operon.

We designed and constructed two new constructs for increased expression of the operon (including pha B). The first construct uses the constitutive promoter [http://parts.igem.org/Part:BBa_J23104 J23104] and the [http://parts.igem.org/Part:BBa_B0034 RBS 0034] with a following scar site TACTAGAG in front of the ATG of the pha C gene. The second construct was designed as a hybrid promoter incorporating BBa_J23104 and the original promoter first, followed by the native promoter and RBS, due to recent results of high expression from a hybrid promoter[http://www.plosone.org/article/info%3Adoi%2F10.1371%2Fjournal.pone.0056321]. The region containing the native promoter and RBS is 352 nucleotides long and might contain important regulatory elements and therefore we were interested to test the hybrid construct in comparison to both the native and constitutive promoter configurations.</

Chassis Design: Tolerance to Waste ▼

We chose the MG1655 E.coli strain as chassis because it constitutively expresses genes that make it resistant to toxic waste degradation products, such as Ethylene glycol. The [http://parts.igem.org/Part:BBa_K892010 aldA] and [http://parts.igem.org/Part:BBa_K892009 fucO] genes have an important role in decreasing the toxic effects of ethylene glycol by converting it into glycolaldehyde which is a link to the cell`s central metabolism. We have received these genes from the registry and future work could be to express these in Bacillus or cellulose-degrading organisms to make them tolerant as well.

Enzyme Secretion Strategy ▼

E.coli is commonly used as a chassis in innovative iGEM projects that aim to prove a concept and make the case for a novel function in a biologically engineered machine. In our case, we aim to degrade and synthesise plastic and the degradation part of our system needs to be extracellular. There are many strategies for secretion. You can read about these on our Secretion Guide page and find the corresponding biobricks and projects. If you are currently in the process of designing a Genetically Engineered Machine in E.coli, this page provides a good starting point to look for information.

We chose the pelB secretion tag as it has been demonstrated to work in many cases, sometimes with very high transport efficiency (3). pelB has been used in iGEM projects for many years and is part of 50+ constructs. The UC-Davis team last year used it to secrete LC-Cutinase, a PET plastic degrading enzyme [http://parts.igem.org/Part:BBa_K936013(BBa_K936013)] successfully, which is somewhat similar to our plastic-degrading enzymes.

References

- Economou A. Following the leader: bacterial protein export through the Sec pathway. Trends in microbiology 1999;7(8) 315-320.

- Thanassi DG, Hultgren SJ. Multiple pathways allow protein secretion across the bacterial outer membrane. Current opinion in cell biology 2000;12(4) 420-430.

- Sletta H, Tondervik A, Hakvag S, Aune TEV, Nedal A, Aune R, et al. The presence of N-terminal secretion signal sequences leads to strong stimulation of the total expression levels of three tested medically important proteins during high-cell-density cultivations of E.coli. Applied and Environmental Microbiology 2007;73(3) 906-912.

Safety ▼

Safety issues regarding our chassis can be found here.

Modelling

What we learnt from the PUR degradation model:

- The model assisted the design of enzyme assays, in particular:

- The toxicity of the PUR degradation product, Ethylene glycol was taken into account in the modelling and it successfully determined the maximum tolerance of the system.

- Ethylene glycol toxicity assays were carried out in the wet lab and were designed according to the results from our model.

What we learnt from the P(3HB) synthesis model:

- Scanning concentration of pha B and sensitivity analysis showed that increasing the concentration of pha B would increase the production rate of P(3HB) in our engineered 'E.coli'.

- Simulations showed that the constitutive promoter J23104 could lead to a higher expression of pha B than the native promoter. As a result the Wet lab team designed and built [http://parts.igem.org/Part:BBa_K1149051 BBa_K1149051], which significantly increased bioplastic production.

- Results from the metabolic model suggested that the synthesis of P(3HB) would be accompanied by a drop of ATP over time and hence allowed us to identify potential limitations of our engineered system. This is important for the Industrial Implementation of our system.

1.0 Polyurethane (PUR) degradation model ▼

Introduction

The efficiencies for polyurethane (PUR) degradation and ethylene glycol production are important for the performance of our system. We built a mathematical and deterministic model that is based on MATLAB extension Simbiology for polyurethane degradation. The model contains the kinetic properties of degradation enzymes that are helpful for the design of assays. As we scaled up the initial concentrations of all substrates to meet the conditions for a bio-reactor, the model can provide preliminary simulations and predictions for the MAPLE system.

Design

Objective

Here are some specific objectives for the model to achieve:

1. The model should contain the gene expression model of the degradation enzymes because the enzyme concentration determines the rate of plastic degradation. In our case for PUR degradation, we used [http://parts.igem.org/Part:BBa_K206000 pBAD strong promoter K206000] for most enzymes. We built the gene expression model based on inducible pBAD promoter, which gene expression rate can be regulated by inducer concentration.

2. The model should show the efficiency of the enzyme secretion to the culture from the cells. It's also important because the enzyme concentration in the culture depends on it. Here we used pelB secretion tag for most enzymes in order to achieve a high efficiency.

3. The model basically predicts how long will take to degrade a known concentration of soluble polyurethane. It is assumed that the enzyme in our assays has the same kinetic properties as the enzyme used in the literature. The model can suggest a suitable concentration of the plastic to use in order to get good results from the assays.