Team:Marburg

From 2013.igem.org

| Line 30: | Line 30: | ||

<a href="https://2013.igem.org/Team:Marburg/Human_Practice:Students"> | <a href="https://2013.igem.org/Team:Marburg/Human_Practice:Students"> | ||

<img src="https://static.igem.org/mediawiki/2013/5/53/Mr_home_school.png" /></a> | <img src="https://static.igem.org/mediawiki/2013/5/53/Mr_home_school.png" /></a> | ||

| - | |||

| - | |||

<a href="https://2013.igem.org/Team:Marburg/Human_Practice:BioTech2020plus"> | <a href="https://2013.igem.org/Team:Marburg/Human_Practice:BioTech2020plus"> | ||

<img src="https://static.igem.org/mediawiki/2013/1/1a/MR_cycle_biotech.png" /></a> | <img src="https://static.igem.org/mediawiki/2013/1/1a/MR_cycle_biotech.png" /></a> | ||

Revision as of 00:25, 22 September 2013

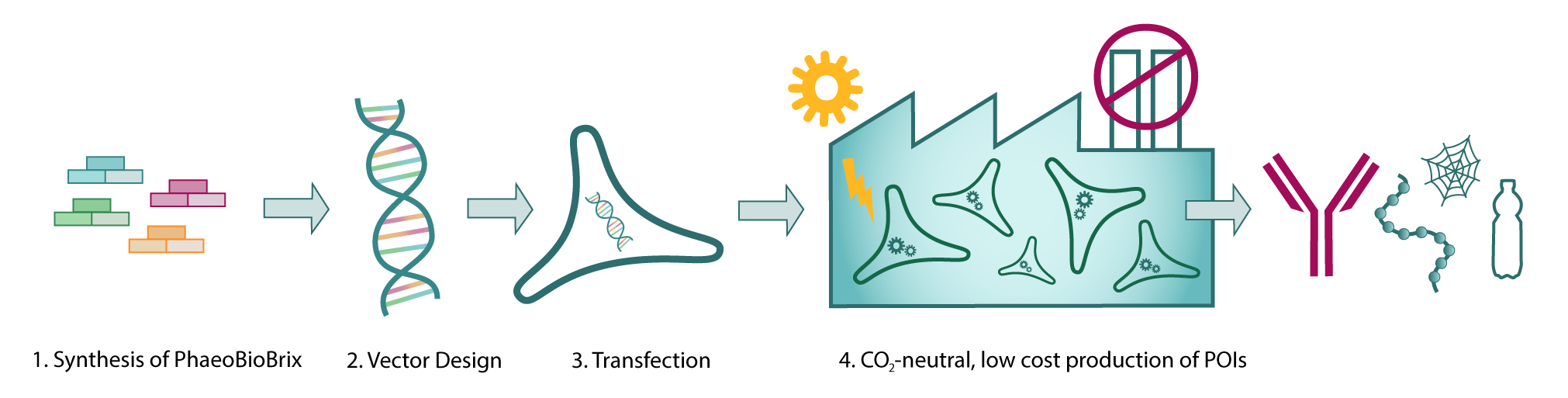

Phaectory: Producing high-value proteins in Phaeodactylum tricornutum

The diatom Phaeodactylum tricornutum is a widely spread organism in marine and limnic waters. Together with about 6000 other species, diatoms belong to the phylum of heterokonts. As a group of great ecological relevance diatoms are responsible for up to 20% of the global CO2 fixation and generate about 40 % of the marine biomass of primary producers (Falkowski et al., 1998, Field et al., 1998).

In addition, diatoms represent an important source of lipids and silicate making them interesting for various biotechnological applications e.g. in biofuel industry, food industry and nanofabrication. "Classical" biotechnology is applied in bacteria, yeast and other fungi. Both need to be fed with carbon sources and the purification of the desired products e.g. high-value proteins is cost intensive, very time consuming and difficult. This is due to the fact that the cells need to be disrupted hence proteins/metabolites have to be removed from the medium.

By using a green cell factory of plants or algae it is possible to produce all kinds of products even high-value proteins like human antibodies in a large scale background. Looking at previous iGEM-projects we recognized that no green chassis was ever introduced into the competition although these organisms perform photosynthesis which enables a carbon dioxide neutral handling. In the photosynthetic process light energy is converted into chemical energy which can be used to fuel different cellular reactions in the cell. Concerning the problem of global warming these organisms offer the possibility to reduce the emission of green house gases and work against the extensive use of fossil fuels. Moreover it is not necessary to feed green algal cell factories with carbohydrates. The world population is continuously growing resulting in a scarceness of nutritions. Our team wants to introduce a green cell factory which is driven by sunlight, produces no carbon dioxide and above all does not compete with the nutrition producing sector.

The microalga P. tricornutum is a green organism incorporating all above mentioned advantages of a green bioreactor. This organism is living from CO2 and light and is able to produce substances like bioplastic, biofuels, spider silk and complex proteins. In our project we decided to produce human antibodies against Hepatitis B. The benefit of proteins produced by P. tricornutum is that the posttranslational modifications fit the human system and need no further adaptations. Another important point is that the desired antibodies are secreted into the pure surrounding medium, so that the purification of the desired product can be omitted. As a plant, microalgae do not secret any other substances and therefore all products produced in Phaectory are already present in a high purity (Hempel et al., 2011).

In order to introduce this organism as a chassis to the iGEM community, we build a toolbox of expression vectors, promoters, selection markers, reporter proteins and signal peptides for P. tricornutum. This allows every future iGEM team to produce their own complex proteins, which can easily be extracted.

"

"